Potato slicer using torsion force

A slicing machine and slicing technology, applied in metal processing and other directions, can solve the problems of insufficient blade cutting ability and slow potato slicing speed, and achieve the effect of increasing speed, increasing cutting ability, and facilitating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

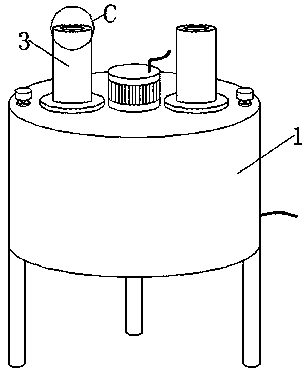

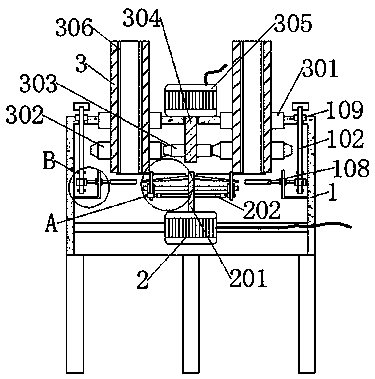

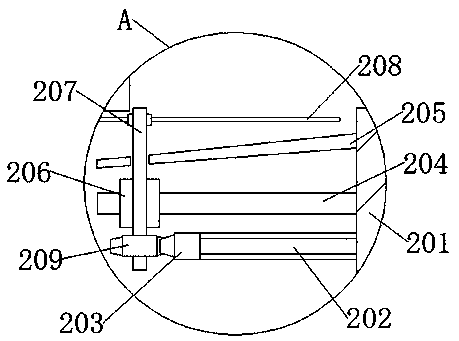

[0028] see Figures 1 to 7 Among them, in the embodiment of the present invention, a potato slicer utilizing torsion includes a protective cover 1, a slicing mechanism and a feeding structure. Three tripods; protective cover 1 includes threaded rod 101, upper washer 102, threaded ring 103, lower washer 104, support rod 105, sliding ring 106, bearing 109, L bar 107 and ejector rod 108, both sides of protective cover 1 top All are embedded and welded with bearings 109, the inner rings of the bearings 109 are welded with threaded rods 101, the bottoms of the threaded rods 101 are welded through the upper washer 102 and the lower washer 104, and the bottoms of the threaded rods 101 are threaded with threaded rings 103 , one side of the threaded ring 103 is provided with two supporting rods 105 and a sliding ring 106, and both sides of the sliding ring 106 are welded with supporting rods 105, and the supporting rods 105 are welded on one side of the threaded ring 103, protecting B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com