A kind of polymer cement waterproof mortar

A waterproof mortar and polymer technology, applied in the field of polymer cement waterproof mortar, can solve the problems of poor wetting of the construction base surface, reduced construction efficiency, poor crack resistance, etc., and achieve smooth and smooth construction surface, outstanding aging resistance, moist The effect of high humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

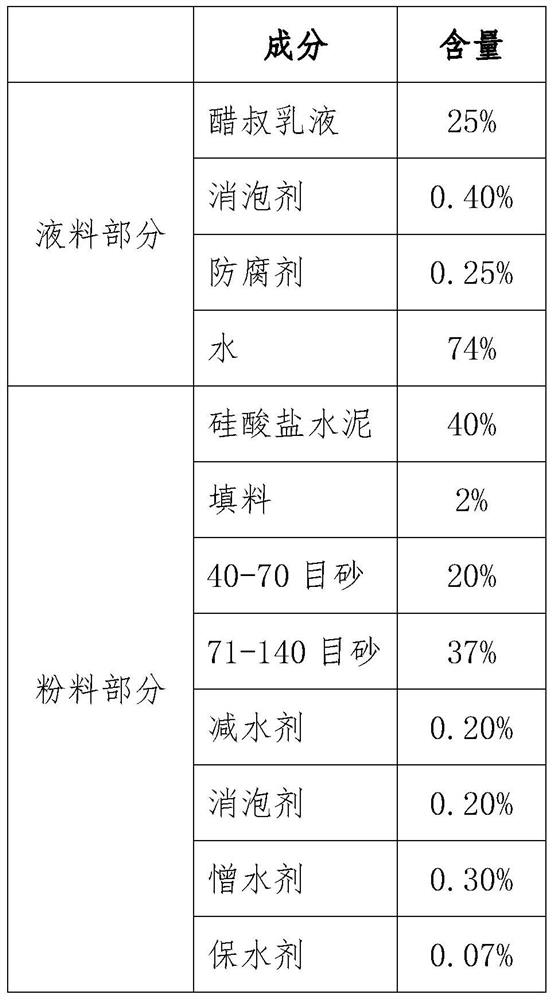

[0040] The present invention provides a polymer cement waterproof mortar, including a liquid component and a powder component, the ratio of the liquid component to the powder component in this embodiment is 0.28:1, and the specific content of each component is as follows As shown in Table 1-1:

[0041] The formula composition list of table 1-1 embodiment 1

[0042]

[0043] Pour the above liquid material into a clean mixing container, then slowly add the powder material while stirring according to the proportion, and fully stir for 3 to 5 minutes until a uniform glue without powder lumps is formed.

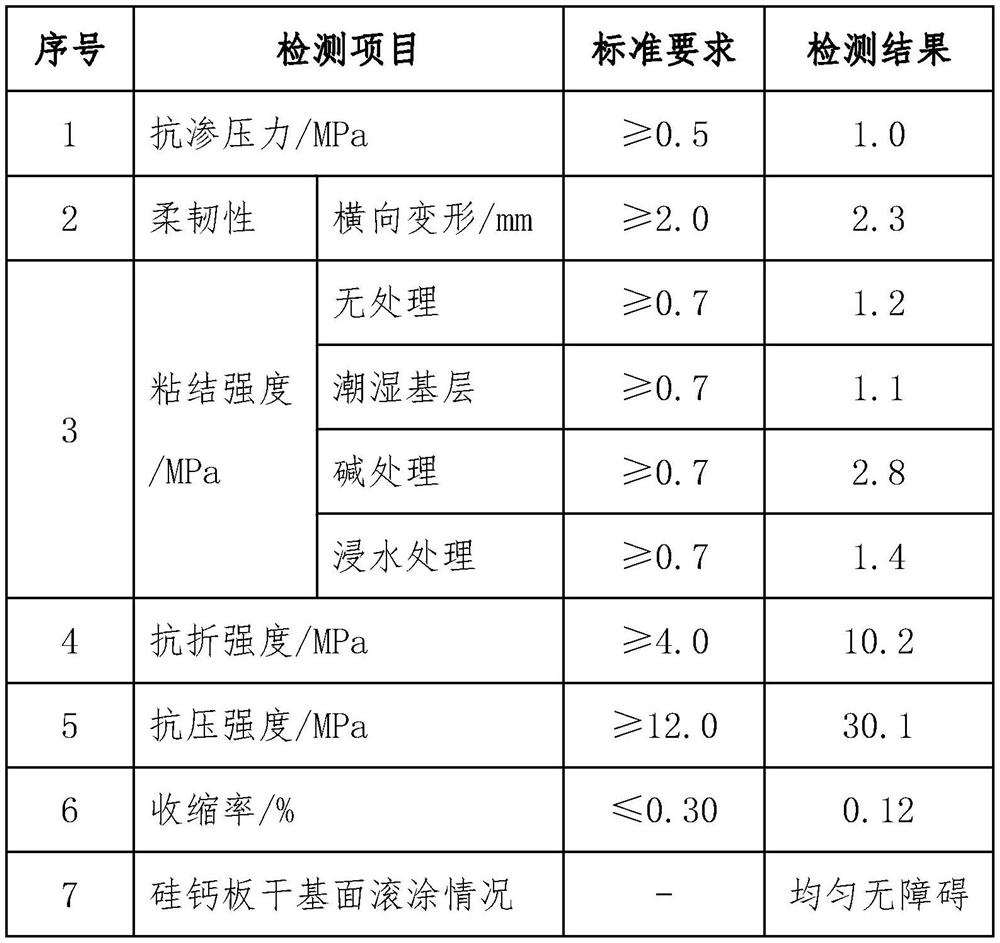

[0044] The polymer cement waterproof mortar of this example was tested according to the national standard, and the test results are shown in Table 1-2:

[0045] Table 1-2 Test result table of Example 1

[0046]

Embodiment 2

[0048] The present invention provides a polymer cement waterproof mortar, including a liquid component and a powder component, the ratio of the liquid component to the powder component in this embodiment is 0.34:1, and the specific content of each component is as follows As shown in Table 2-1:

[0049] The formula composition list of table 2-1 embodiment 2

[0050]

[0051]

[0052] Pour the above liquid material into a clean mixing container, then slowly add the powder material while stirring according to the proportion, and fully stir for 3 to 5 minutes until a uniform glue without powder lumps is formed.

[0053] The polymer cement waterproof mortar of this example was tested according to the national standard, and the test results are shown in Table 2-2:

[0054] Table 2-2 Test result table of Example 2

[0055]

[0056]

Embodiment 3

[0058] The present invention provides a polymer cement waterproof mortar, including a liquid component and a powder component, the ratio of the liquid component to the powder component in this embodiment is 0.37:1, and the specific content of each component is as follows As shown in Table 3-1:

[0059] The formula composition table of table 3-1 embodiment 3

[0060]

[0061]

[0062] Pour the above liquid material into a clean mixing container, then slowly add the powder material while stirring according to the proportion, and fully stir for 3 to 5 minutes until a uniform glue without powder lumps is formed.

[0063] The polymer cement waterproof mortar of this example was tested according to the national standard, and the test results are shown in Table 3-2:

[0064] Table 3-2 Test result table of Example 3

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com