Electrostatic device

An electrostatic and electrostatic field technology, which is used in textiles and papermaking, continuous winding spinning machines, open-end spinning machines, etc., can solve the interference of electrostatic spinning production efficiency, difficulty in improving, and unreasonable design of the twister structure. and other problems, to reduce the probability of insufficient twist, simplify the stress process, and avoid the effect of breaking the fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

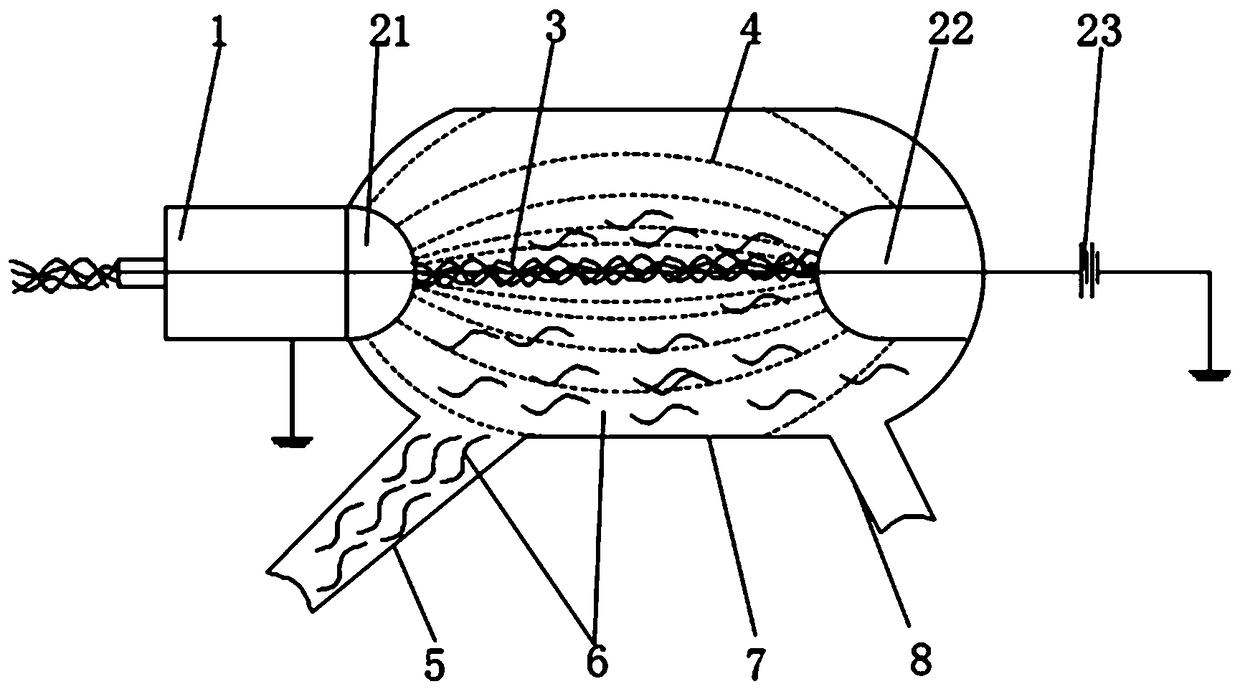

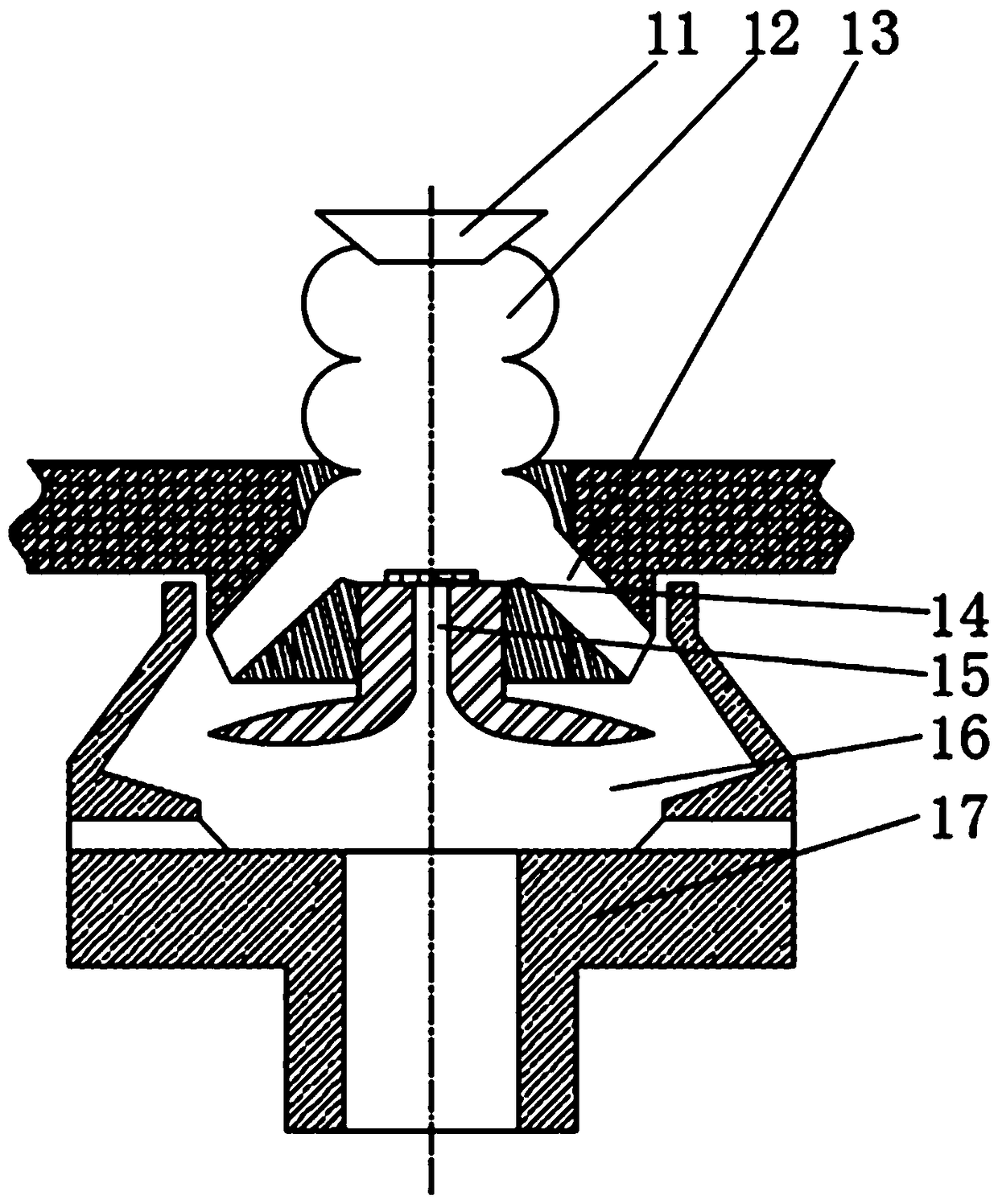

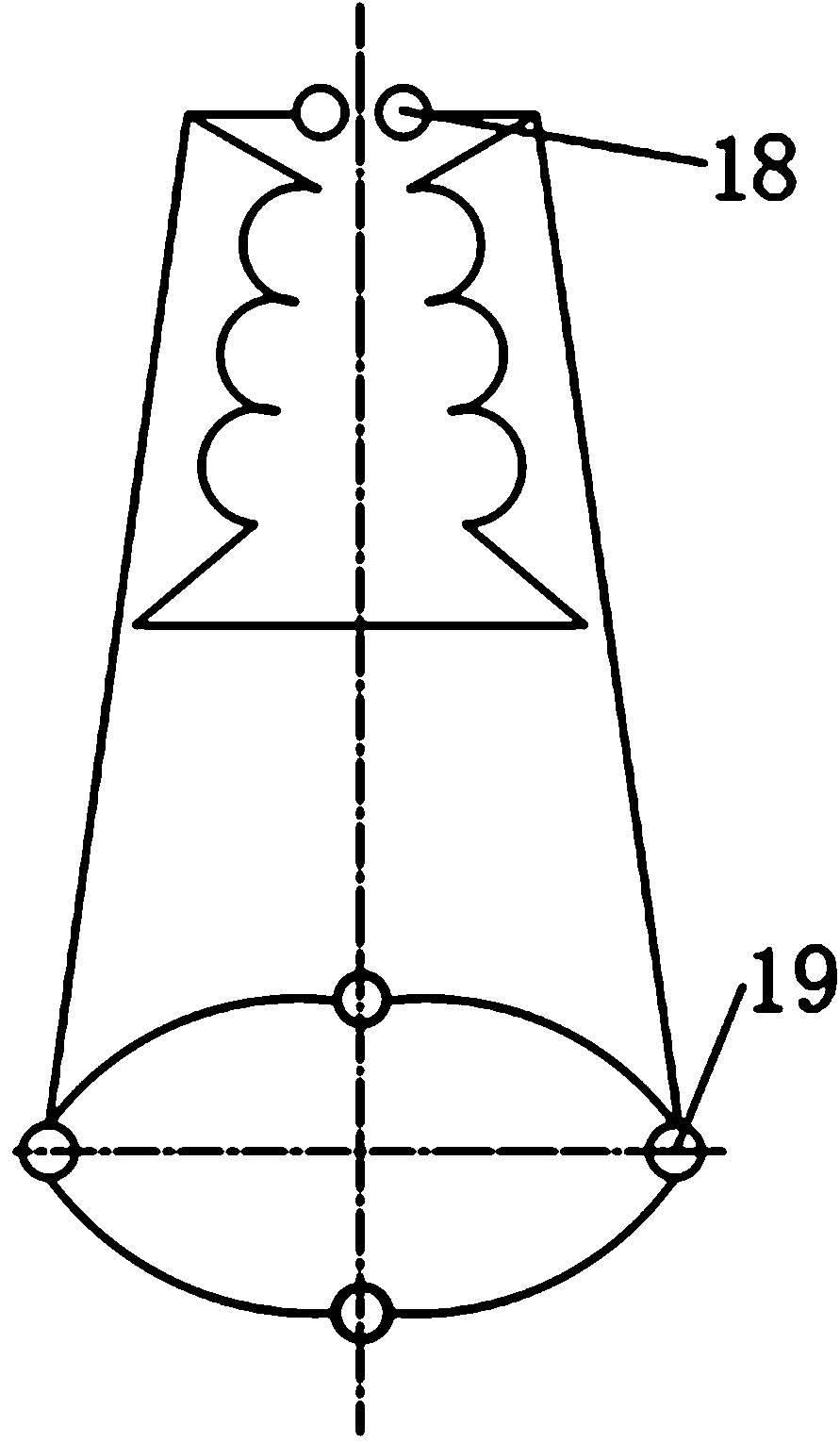

[0026] Such as Figure 1-3 As shown, an electrostatic device of the present invention includes a supply port 5, an electrostatic field generator, and an adder 1, and the electrostatic field generator includes a high-voltage power supply 23, a negative electrode 21, a positive electrode 22, and a device for protecting the electrostatic field environment Electric field cover 7, described negative electrode 21, positive electrode 22 are under the action of high-voltage power source 23, form power line 4 in electric field cover 7; Electric field cover 7 is provided with supply port 5 and suction duct 8, and described supply port 5 and suction The air duct 8 acts to guide the fiber 6 into the electric field cover 7, the electric force line 4 guides the fiber 6 to attach to the free-end whisker 3, and the free-end whisker 3 guides the fiber 6 to enter the twister 1 to be twisted into a yarn; Described adder 1 comprises bell mouth 11, and described bell mouth 11 is used for obtaining...

Embodiment 2

[0028] This embodiment makes the following further limitations on the basis of embodiment 1: as Figure 2-4As shown, a blocking net 14 is provided between the air passage 15 and the transition pipe 12 . The barrier net 14 is used to prevent the fiber 6 from being directly introduced into the condensation tank 16 from the air hole, so as to avoid the direct export of the untwisted fiber 6 . The blocking net 14 is provided with a cross-shaped frame inside, which is spliced with the end face of the air channel 15 through an adhesive, and the center of the cross-shaped frame is on the central axis of the air channel 15 . The cross-shaped retainer plays the role of a small twister, and when a small amount of fiber 6 is directly introduced into the condensation tank 16 from the air channel 15, due to the rotation of the twister, the cross-shaped retainer can also be used for this part of the fiber 6. Twist, and will be on the central axis of the main twisted fiber 6, thereby redu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap