Turbine disk cavity sealing structure with bypass gas entraining

A turbine disc and bleed air technology, applied in the direction of leakage prevention, engine components, machines/engines, etc., can solve the problems of turbine performance decline, turbine efficiency reduction, loss increase, etc., to achieve good economy and realizability, secondary Reduced flow loss and improved turbine efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

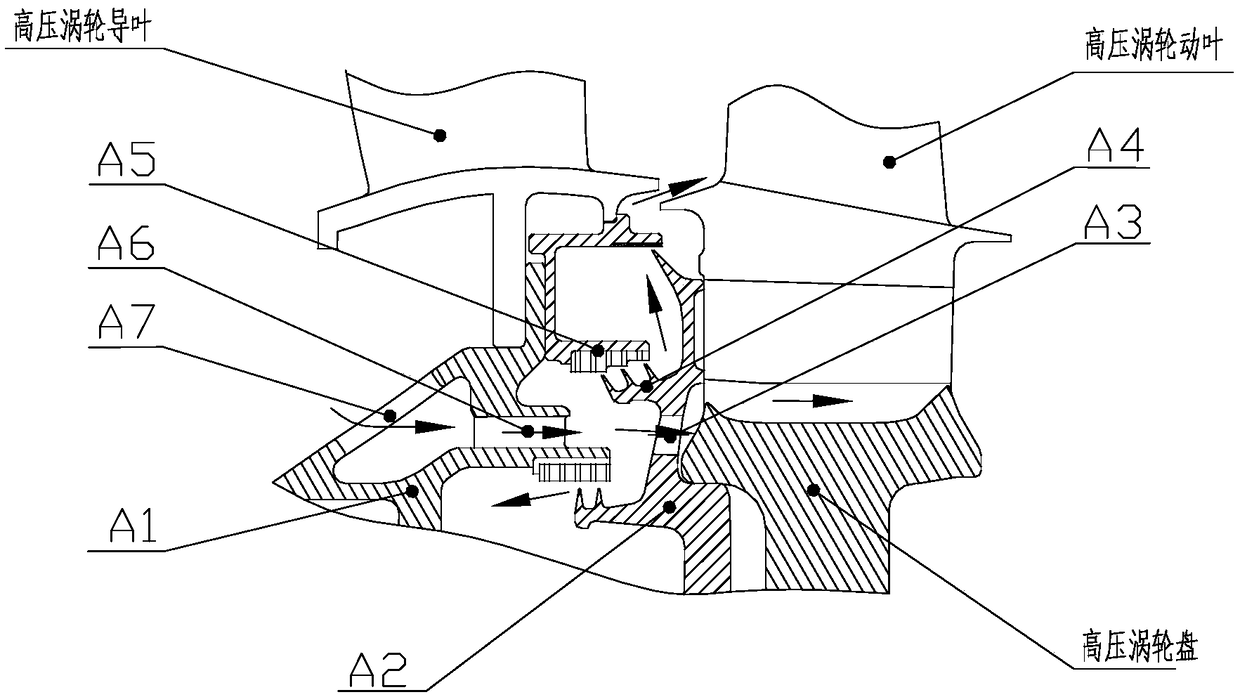

[0024] A typical existing turbine disc cavity sealing structure is as follows: figure 1 As shown, the structure is composed of A1 inner support ring, A2 front baffle, A3 front baffle air intake, A4 sealing grate, A5 honeycomb structure, A6 pre-rotating nozzle, A7 inner support ring air intake. Among them, the inner support ring of A1 is connected with the guide vane of the high-pressure turbine through the snap ring, and the front baffle of A2 is connected with the rotor blade of the turbine by a fast buckle structure. The working principle of the sealing structure of the turbine disk cavity is: the cold air introduced from the front of the compressor enters the gas collection chamber through the A7 inner support ring air intake hole on the A1 inner support ring, and is divided into three strands after being depressurized and accelerated by the A6 pre-rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com