An aeroengine residual life prediction method

A technology of aero-engine and prediction method, which is applied in the direction of internal combustion engine testing, special data processing applications, instruments, etc., can solve problems such as difficulties, and achieve the effect of improving robustness and avoiding biased estimation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]In order to describe the technical solution disclosed in the present invention in detail, further elaboration will be made below in conjunction with the accompanying drawings and specific embodiments.

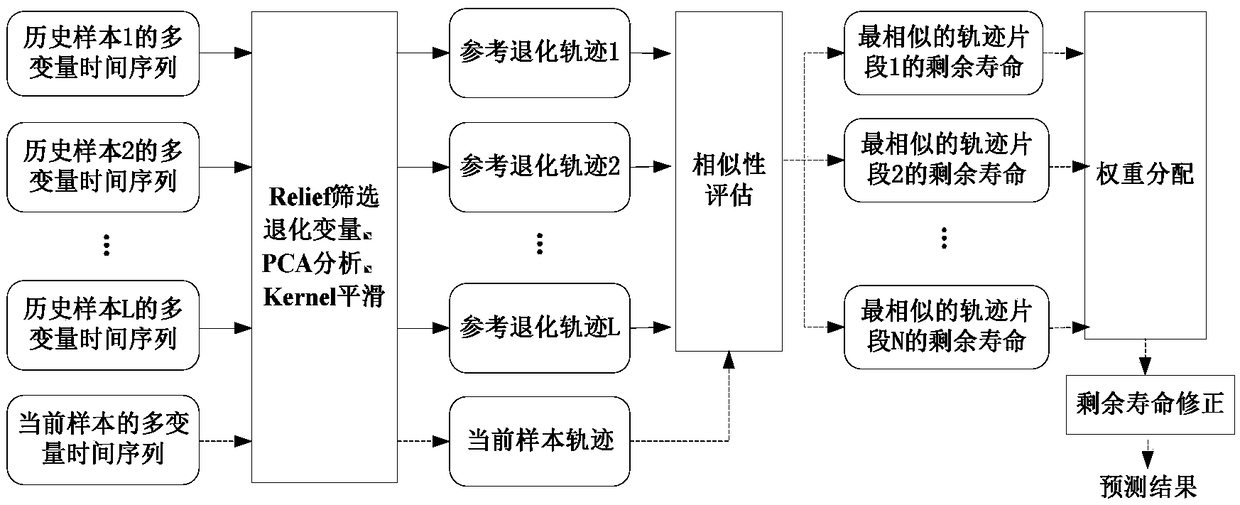

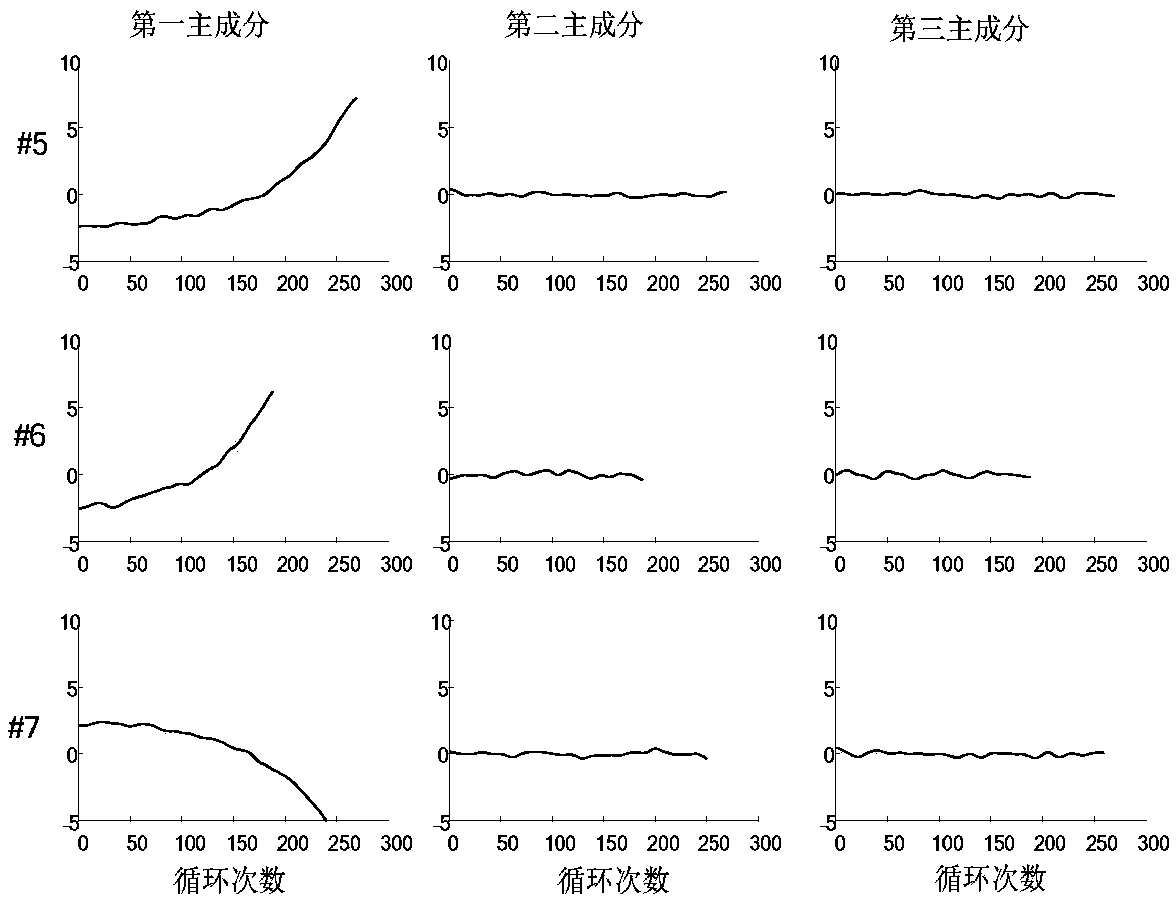

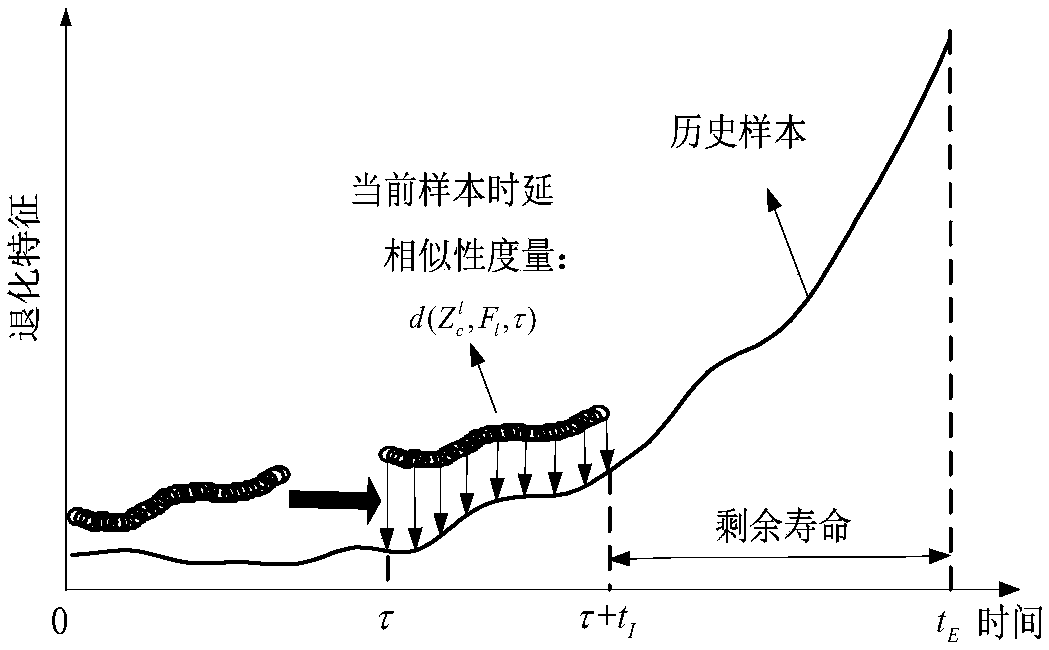

[0040] The invention relates to a method for predicting the remaining life of an aero-engine, which belongs to the technology of similarity modeling and remaining life prediction of aero-engine performance degradation characteristics. The present invention first performs degradation feature screening, principal component analysis (PCA), and Kernel smoothing to extract low-dimensional orthogonal degradation features and actual degradation tracks of the multi-dimensional time series data of the aero-engine through the Relief algorithm; then performs similarity matching on the degradation tracks, Find the set of degraded trajectory fragments in a group of historical samples that are most similar to the trajectory fragments of the sample to be tested, and use the density weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com