Flexible display panels, display equipment and preparation methods for flexible display panels

A flexible display and panel technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as affecting the life of flexible display panels, reducing water and oxygen barrier capabilities, and film packaging failure, and preventing peeling. , The effect of improving bending strength and increasing material density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and effect of the present application more clear and definite, the present application will be further described in detail below with reference to the accompanying drawings and examples.

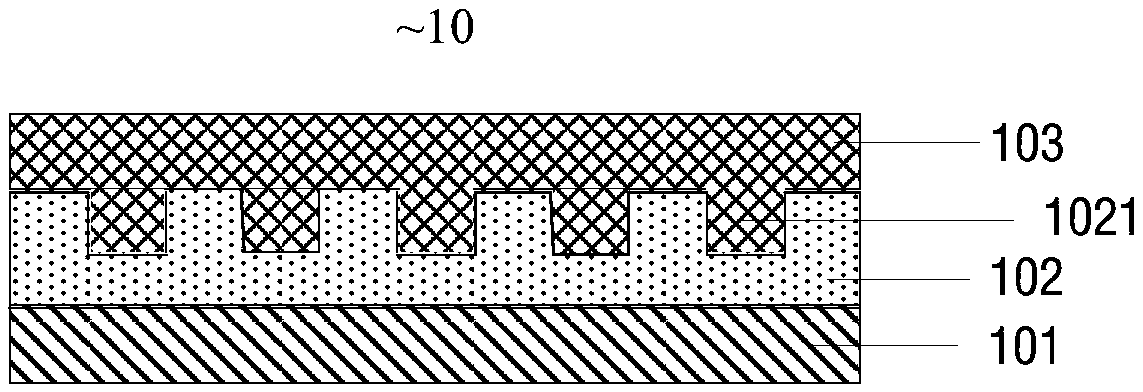

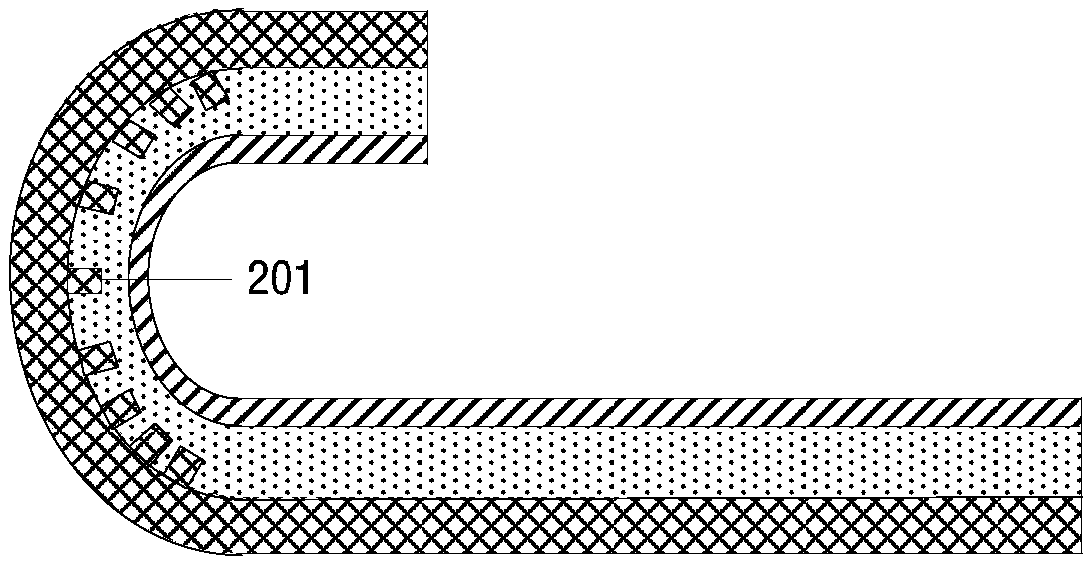

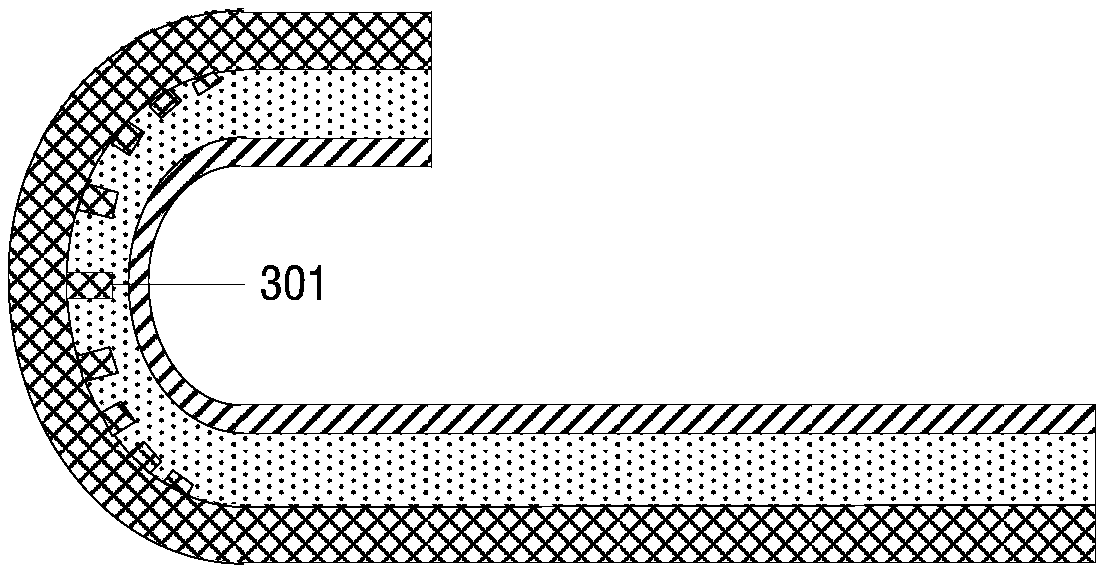

[0028] The present application provides a flexible display panel, which includes a thin film encapsulation layer, and the thin film encapsulation layer includes an organic encapsulation layer and an inorganic encapsulation layer. Among them, a plurality of grooves are provided on the side of the organic packaging layer away from the light-emitting layer, and the inorganic packaging layer material fills the grooves, so that the inorganic packaging material is embedded in the organic packaging material, which can strengthen the gap between the organic packaging layer and the inorganic packaging layer. Especially in the bending process of the display panel, it can prevent the peeling between layers, thereby improving the packaging performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com