Information control system of numerical control manufacturing machine tool for assembling cables

A technology of information control and machine tools, which is applied in the direction of circuits, electrical components, circuit/collector parts, etc., can solve the problems of difficulty in blanking and recovery of residual materials, inability to factory prefabricate cable assembly components, long construction period, etc., to achieve The peeling and cutting effect is accurate and efficient, the on-site assembly time is shortened, and the effect of measuring work is eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

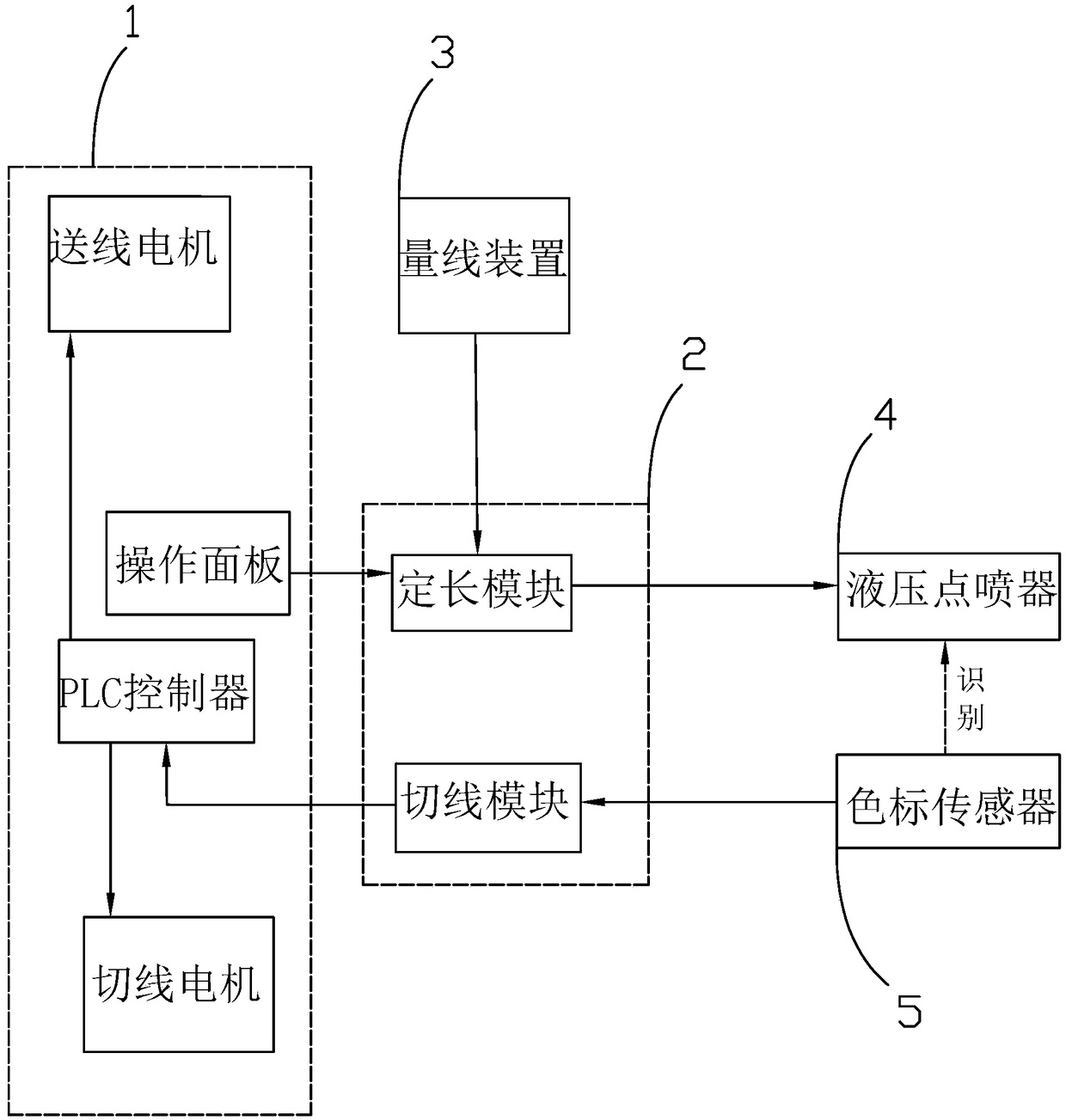

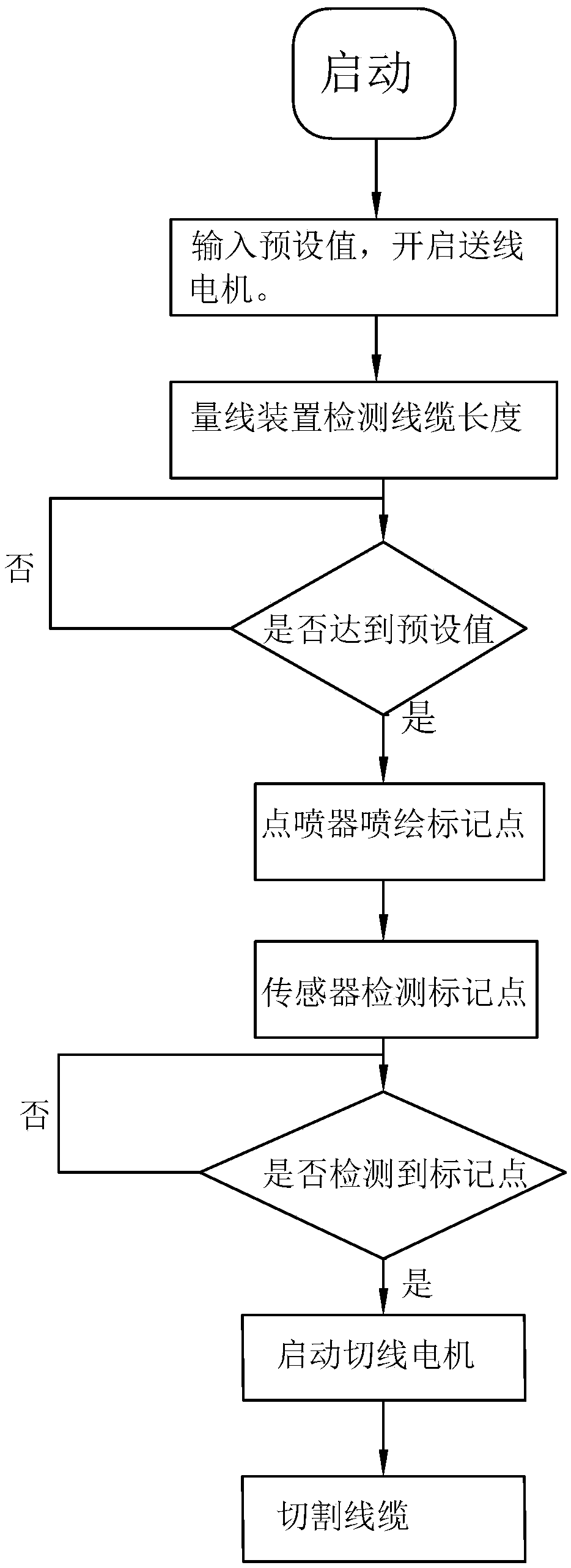

[0027] Example: Assemble the information control system of the cable CNC production machine, such as figure 1 As shown, it includes a control unit 1, a processing unit 2, an inkjet unit 3, a measurement unit 4 and an identification unit 5; the control unit is connected to the processing unit, and the inkjet unit, the measurement unit and the identification unit are all connected to the processing unit.

[0028] The control unit includes an operation panel, a PLC controller, and a wire feeding motor and a thread trimming motor controlled by the PLC controller.

[0029] The processing unit includes a CNC processor. The CNC processor is provided with a fixed-length module and a line-cutting module. The input end of the fixed-length module is connected to the operation panel, and the output end of the line-cutting module is connected to the input end of the PLC controller.

[0030] The measuring unit includes a line measuring device, and the output end of the line measuring device...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap