Plate cutting device

A cutting device and plate technology, applied in the field of parts processing, can solve problems such as low cutting accuracy, human injury, and potential safety hazards, and achieve the effect of facilitating centralized collection and reducing cutting errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further detailed explanation through specific implementation mode below:

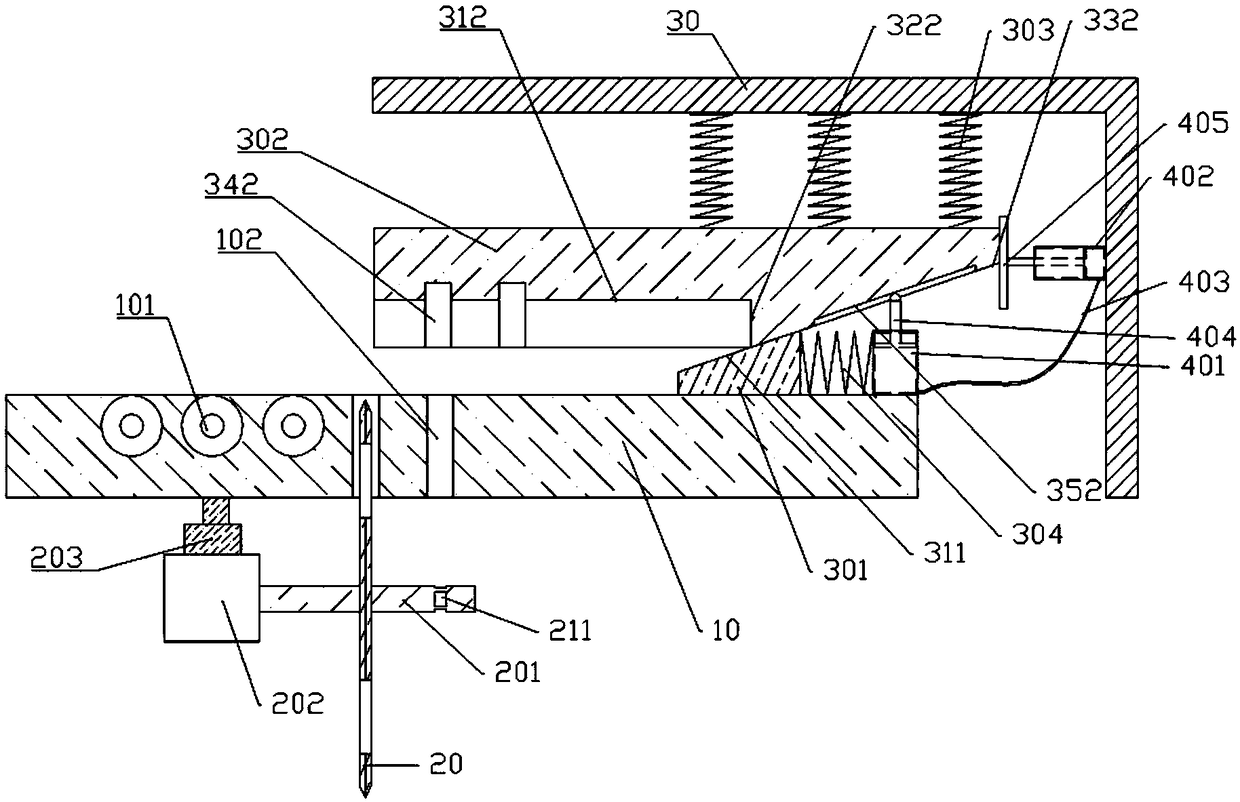

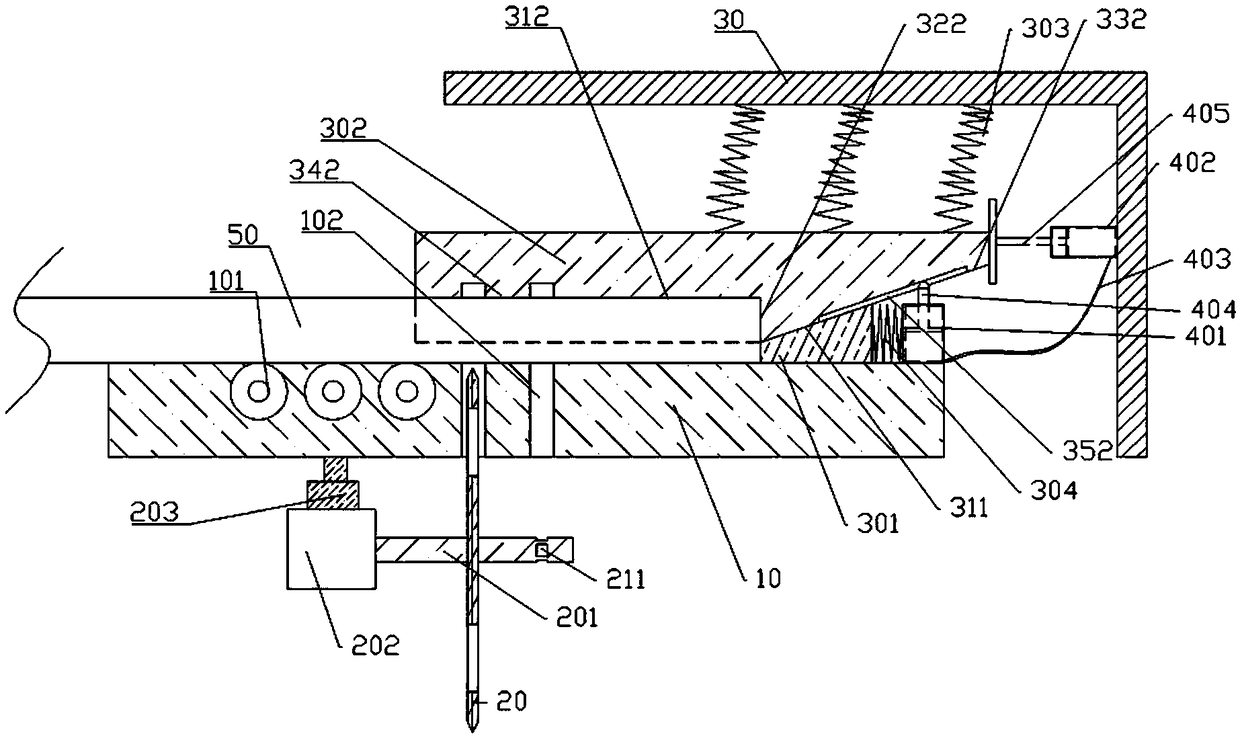

[0024] The reference signs in the accompanying drawings of the description include: machine table 10, transmission wheel 101, knife hole 102, cutting knife 20, rotating shaft 201, socket 211, motor 202, third cylinder 203, frame 30, block 301, first Wedge surface 311, pressure block 302, horizontal surface 312, vertical surface 322, second wedge surface 332, knife relief groove 342, chute 352, extension spring 303, compression spring 304, first cylinder 401, second cylinder 402, connection Tube 403 , first slide bar 404 , second slide bar 405 , plate 50 .

[0025] The embodiment is basically as attached figure 1 And attached figure 2 Shown: a plate cutting device, including a machine table 10, a cutting knife 20, a rotating transmission wheel 101, a rotating shaft 201, a control unit, a motor 202 that drives the rotating shaft 201 to rotate, and a limiting mechanism for limiting the plate 50. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com