A process for preparing aluminum-silicon solution by dissolution of laterite nickel ore smelting slag

A technology of laterite nickel ore and process method, applied in the fields of environment and materials, can solve the problems of low process efficiency and long time consumption, and achieve the effects of making full use of, improving the recovery rate and shortening the process operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

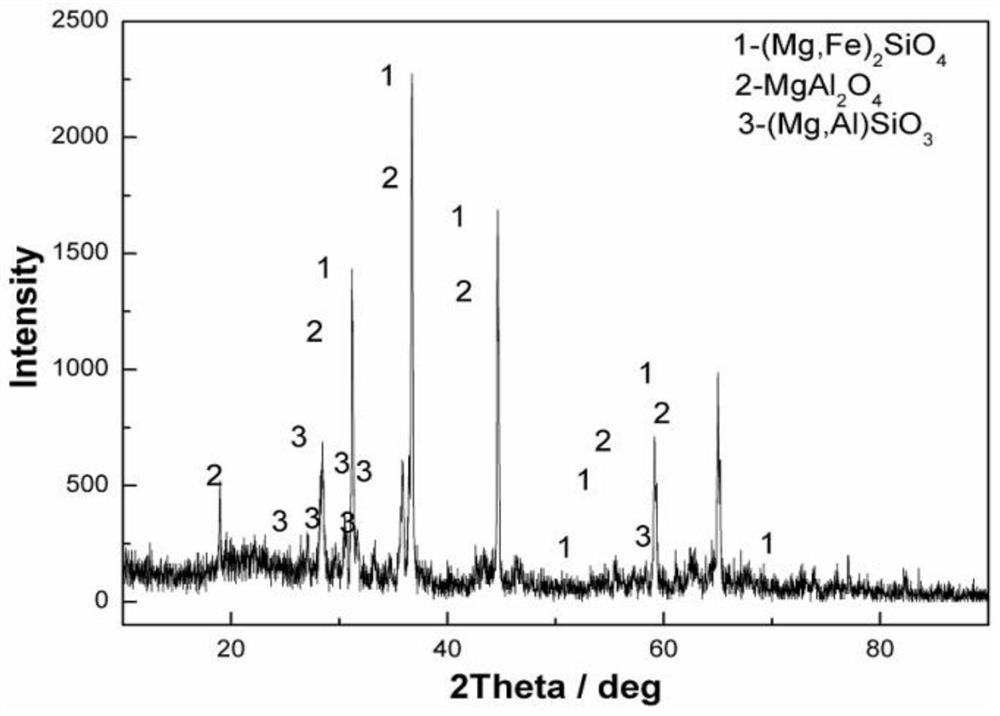

[0024] XRD analysis of metallurgical slag raw materials such as figure 1 As shown, the main phase composition of laterite nickel slag is (Mg,Fe) 2 SiO 4 , MgAl 2 o 4 , (Mg,Al)SiO 3 etc., its chemical composition is as shown in Table 1;

[0025] Table 1 Chemical analysis results (mass fraction) of laterite nickel ore metallurgical slag

[0026]

[0027] Crushing and grinding: The solid laterite nickel ore smelting slag is broken and ground to about 200 mesh.

[0028] Ingredients mixing: finely ground smelting slag and solid Na 2 CO 3 Mix with NaOH in a ratio of 3:7:10.

[0029] High-temperature alkali fusion: Put the above-mentioned mixture in a container, heat it to 600°C and keep it warm for 40 minutes, take it out and cool it, crush it and grind it for later use.

[0030] Water immersion: Add about 4% Al(OH) to the above alkali-melted material 3 , leached with deionized water, and kept at 80° C. for 45 minutes to obtain a crude aluminum-silicon eluate mixed with...

Embodiment 2

[0033] Metallurgical slag raw material is identical with embodiment 2.

[0034] Crushing and grinding: The solid laterite nickel ore smelting slag is broken and ground to about 200 mesh.

[0035] Ingredients mixing: finely ground smelting slag and solid Na 2 CO 3 Mix with NaOH in a ratio of 3:7:10.

[0036] High-temperature alkali fusion: Put the above-mentioned mixture in a container, heat it to 600°C and keep it warm for 40 minutes, take it out and cool it, crush it and grind it for later use.

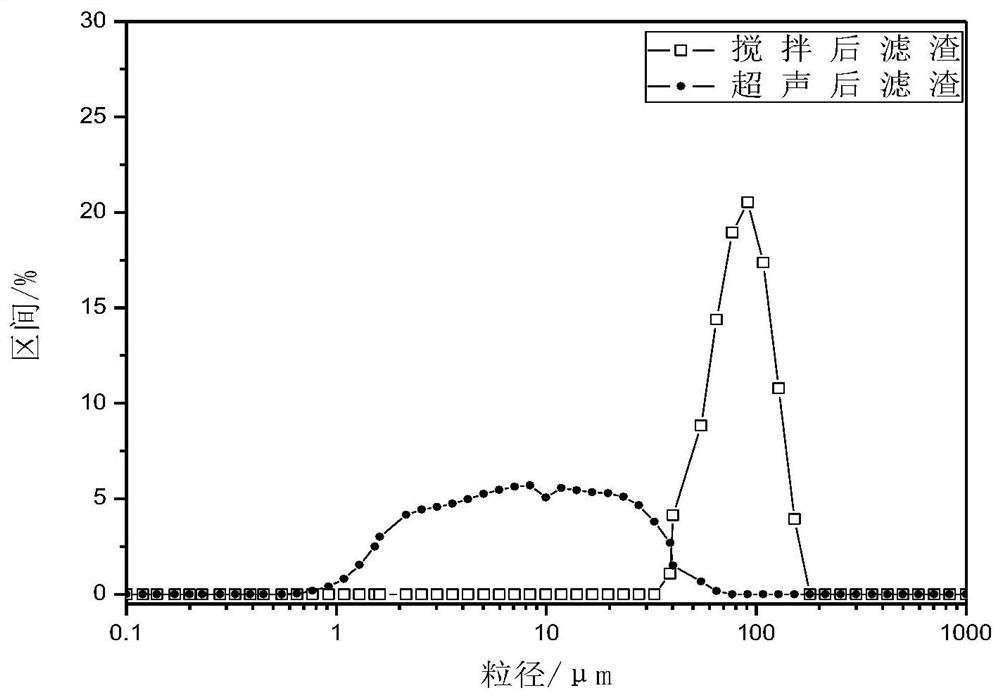

[0037] Mechanical stirring water immersion: add about 4% Al(OH) to the above alkali-melted material 3 , leached with deionized water, applied strong mechanical agitation (500r / min), and kept at 80°C for 45 minutes to obtain a crude aluminum-silicon elution liquid mixed with liquid and solid.

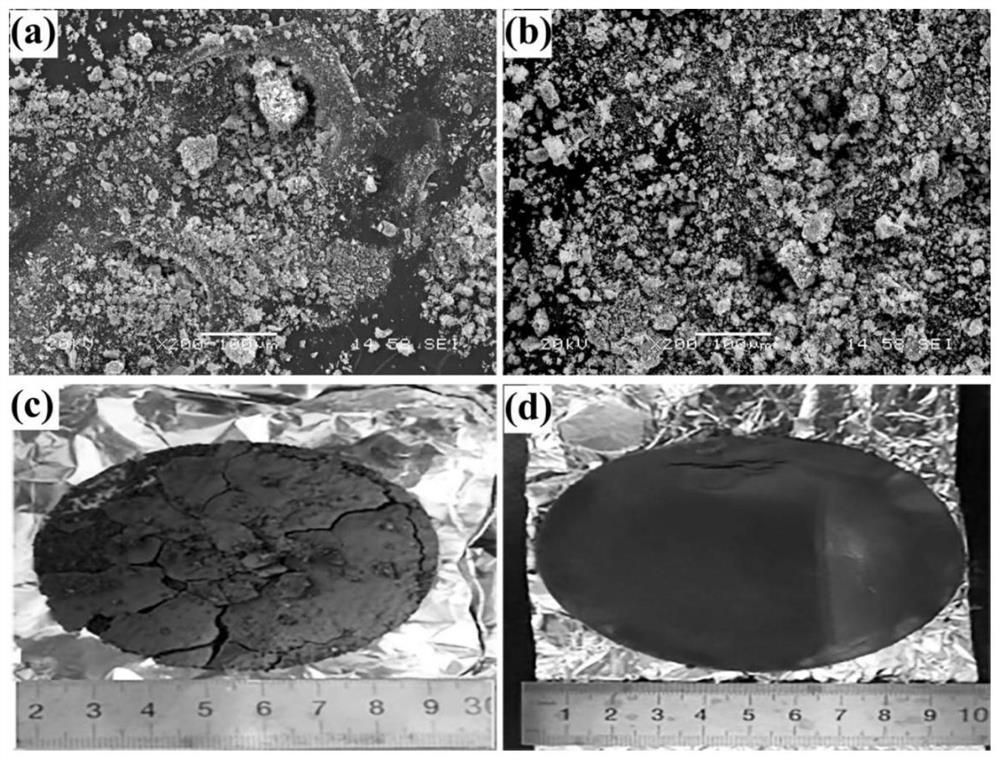

[0038] Solid-liquid separation: The above-mentioned crude aluminum-silicon eluate mixed with water-slag is subjected to suction filtration for liquid-solid separation to obtain aluminum-sil...

Embodiment 3

[0040] The metallurgical slag raw material is the same as that in Examples 1 and 2; crushing and grinding: the solid laterite nickel ore smelting slag is crushed and ground to about 200 mesh.

[0041] Ingredients mixing: finely ground smelting slag and solid Na 2 CO 3 Mix with NaOH in a ratio of 3:7.5:10.5.

[0042] High-temperature alkali fusion: Put the above-mentioned mixture in a container, heat it to 600°C and keep it warm for 40 minutes, take it out and cool it, crush it and grind it for later use.

[0043] Ultrasonic enhanced water immersion: Add about 4% Al(OH) to the above alkali-melted material 3 , leaching with deionized water, applying ultrasonication (intermittent mode, alternately on for 3min-off for 1.5min), and after maintaining at 80°C for 45min, a crude aluminum-silicon elution liquid mixed with liquid and solid was obtained.

[0044]Solid-liquid separation: The above-mentioned crude aluminum-silicon eluate mixed with water-slag is subjected to suction fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com