self-embedded retaining wall

A retaining wall and self-embedded technology, which is applied in container cultivation, construction, artificial islands, etc., can solve problems such as inconvenient construction, and achieve the effects of convenient installation, sufficient water, and high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

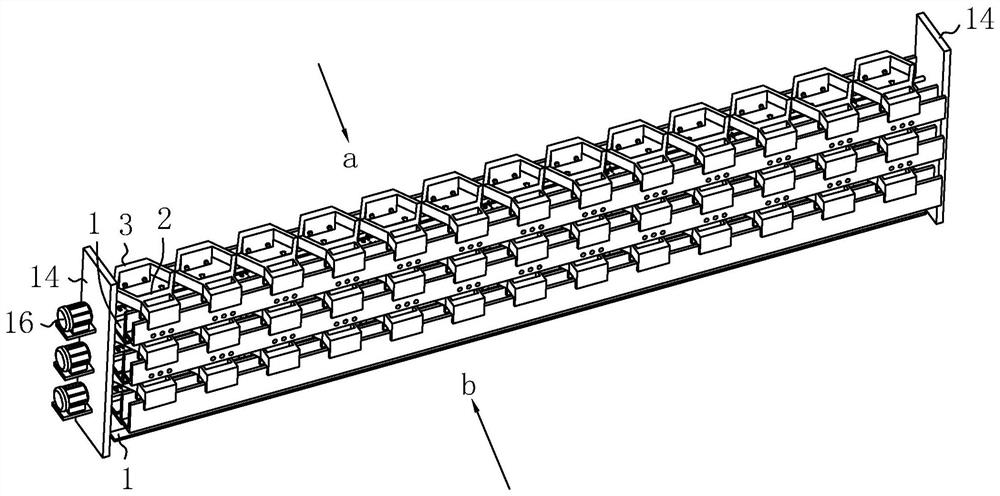

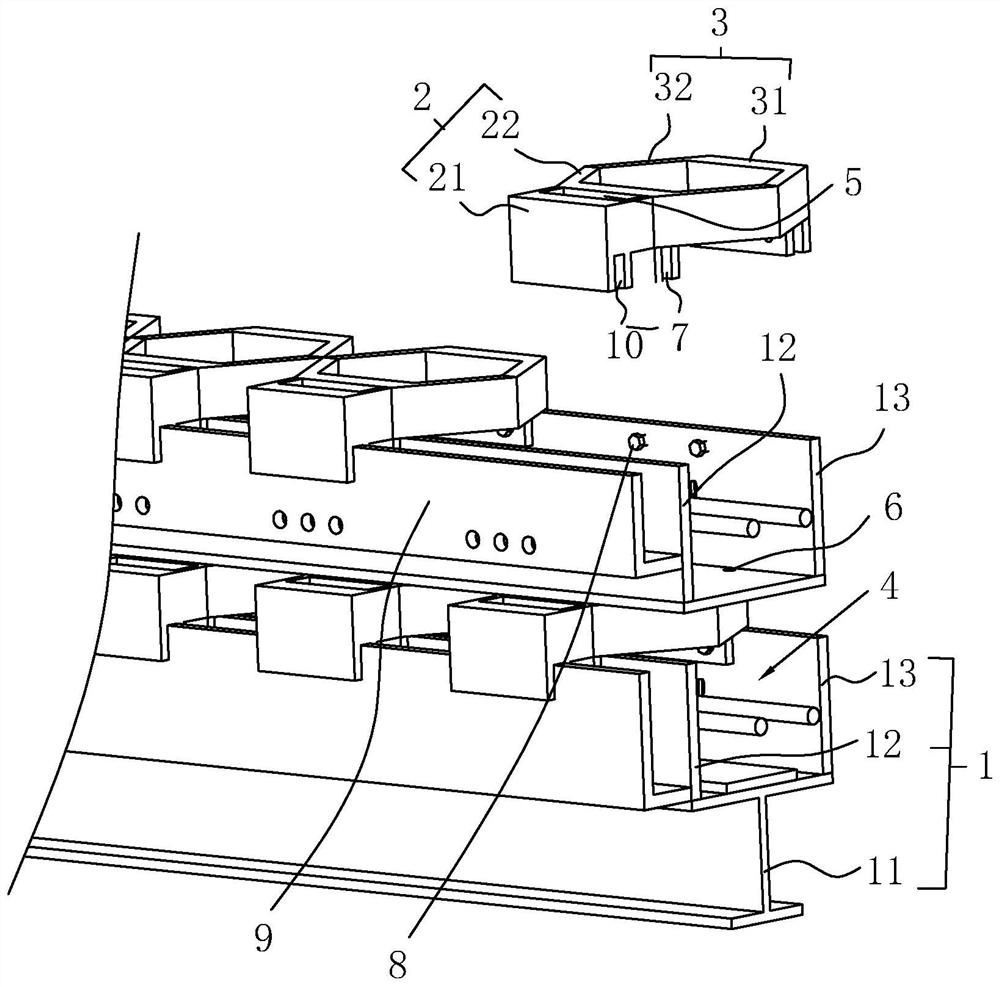

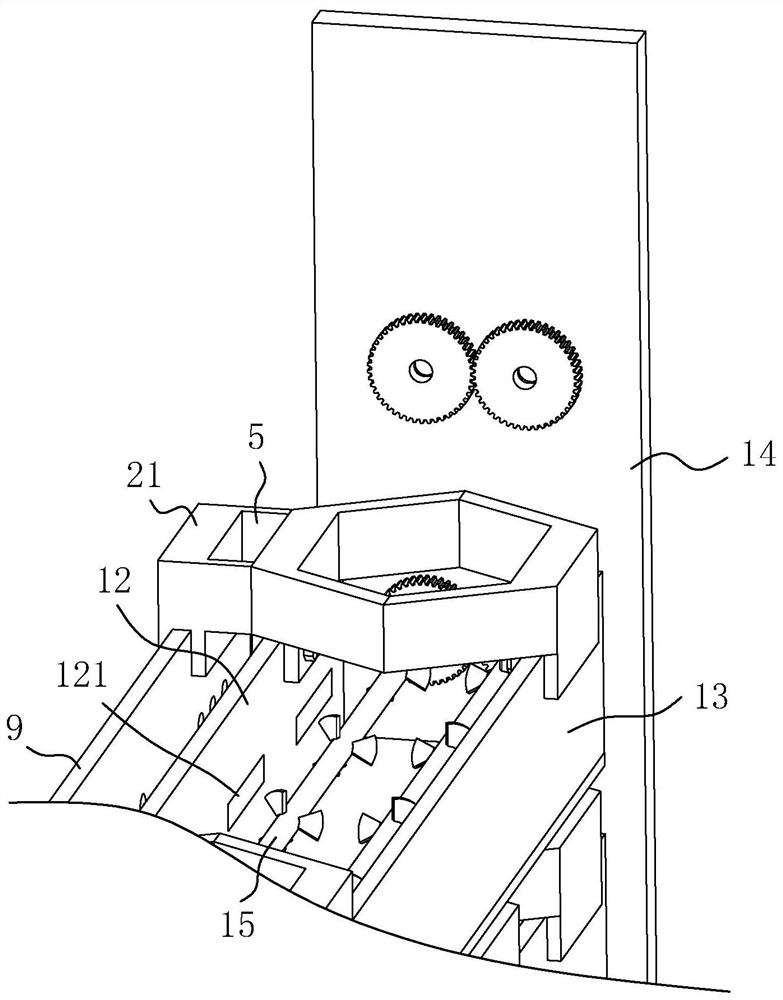

[0037] refer to figure 1 , is a self-embedded retaining wall disclosed by the present invention, comprising a bearing frame 1 screwed on the old wall, a first splicing body 2 inserted on the bearing frame 1 and facing the water side, and a first joint body 2 facing the filling side The second splicing body 3, the first splicing body 2, and the second splicing body 3 are surrounded to form a closed ring body, and the carrier frame 1 is used to install on the old wall, and the carrier frame 1 is used as a base to ensure that the first splicing body 2 and the second splicing body The body 3 has the same reference plane when installed, and then the first splicing body 2 and the second splicing body 3 are plugged on the carrier frame 1. Compared with the construction method of using a single brick to stack up in the prior art, the construction method is greatly improved. The convenience and quickness of forming the self-embedded retaining wall.

[0038] refer to figure 1 and fi...

Embodiment 2

[0044] A self-embedded retaining wall, the construction method of the retaining wall comprises the following steps:

[0045] (1) Clean the dust on the surface of the old wall, and screw the lower surface of the I-beam to the old wall;

[0046] (2) Weld the first board and the second board to both sides of the upper surface of the I-beam along the length direction to form reserved grooves, weld the L-shaped baffle to the outer wall of the first board, and the L-shaped baffle A planting groove is formed between the first inserting board;

[0047] (3) Weld the end plates to both ends of the I-beam, and install the motor and the biaxial stirring paddle;

[0048] (4) Fill the reserved groove with soil, and then fix the first joint body and the second joint body on the first board and the second board by screws;

[0049] (5) Repeat the above steps until a self-embedded retaining wall of the desired height is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com