Construction process of manual hole-digging cast-in-place pile in weak-weathered rock or medium-weathered rock stratum area

A technology of artificial digging piles and construction technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as affecting the safety of surrounding buildings and neighbors' claims disputes, reducing the impact of shock waves, improving tunneling speed, and saving energy. the effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

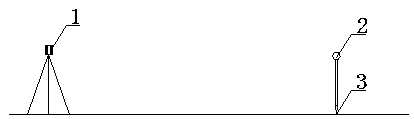

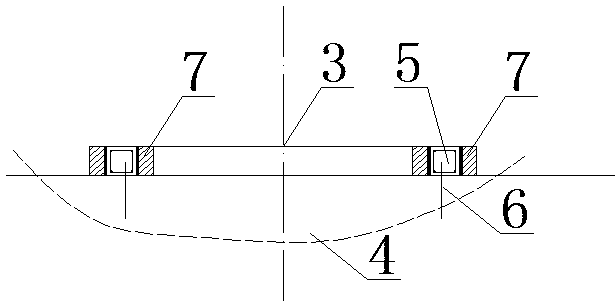

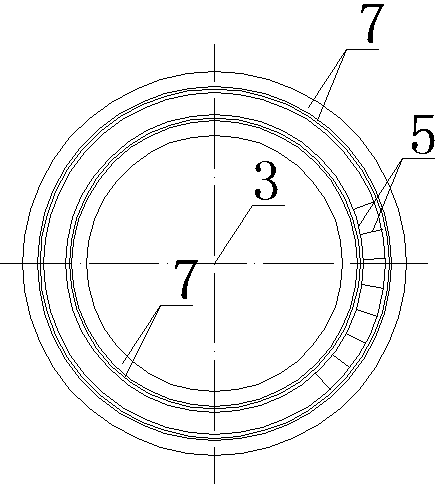

[0031] Such as Figure 1-7 As shown, the construction technology of artificially dug holes in the weakly weathered rock or medium weathered rock formation includes the following steps:

[0032] S1: Use the GPS total station 1 and the GPC total station measuring rod 2 to form a measuring equipment system, and determine the centerline 3 of the manual excavation pile;

[0033] S2: At the position of the wellhead 4 of the manual digging pile, bind the reinforcement skeleton 5 of the well ring with the reserved reinforcement head 6 of the retaining wall of the manual digging pile, and support the well ring template 7;

[0034] S3: After dismantling the cast-in-place concrete well circle template 7, a complete reinforced concrete well circle 8 is formed, and a lifting frame 9, a blower 10, and an air duct 11 are installed at the well circle and connected to manual digging piles for soil excavation or rock drilling work surface; manual excavation of the earthwork in the well circle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com