Intelligent detection system and method for micro-pore shape of fuel injection nozzle based on machine vision

A technology of intelligent detection and machine vision, applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problems of low efficiency, high misjudgment rate, uneven classification quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

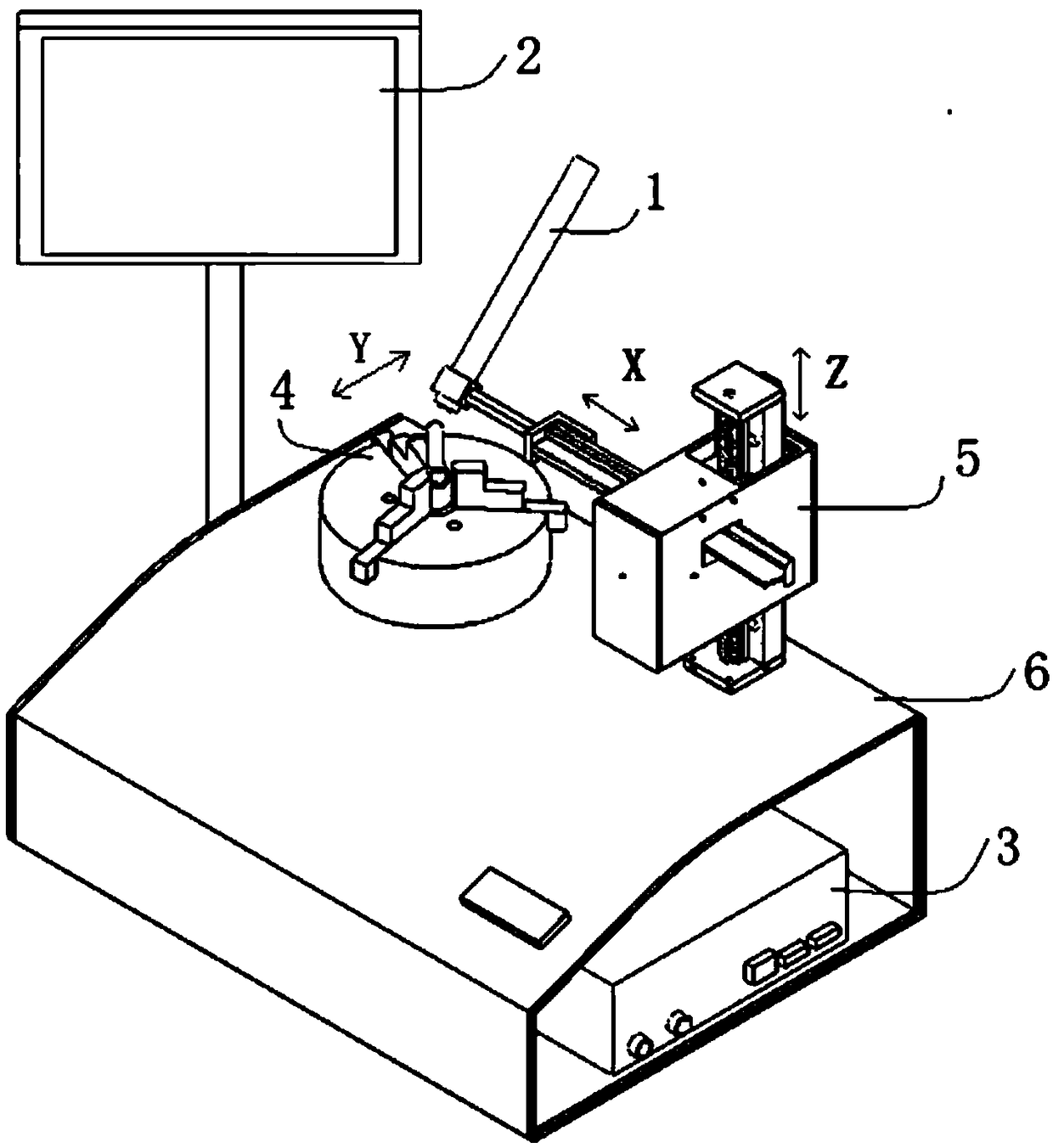

[0076] See eg figure 1 , in the example shown in this figure, the intelligent detection system for the micropore shape of the fuel injector includes an electron microscope 1 , an image processing system 2 , a main control system 3 , a rotating stage 4 , a positioning mechanism 5 and a shell 6 . The electron microscope 1 is fixed on the positioning mechanism 5 . The rotating stage 4 and the positioning mechanism 5 are fixed on the upper surface of the shell 6, the main control system 3 is placed inside the shell 6, and the image processing system 2 can be fixedly connected with the shell 6, or can be independent of each other. The positioning mechanism 5 , the image processing system 2 and the rotating stage 4 are respectively connected to the main control system 3 .

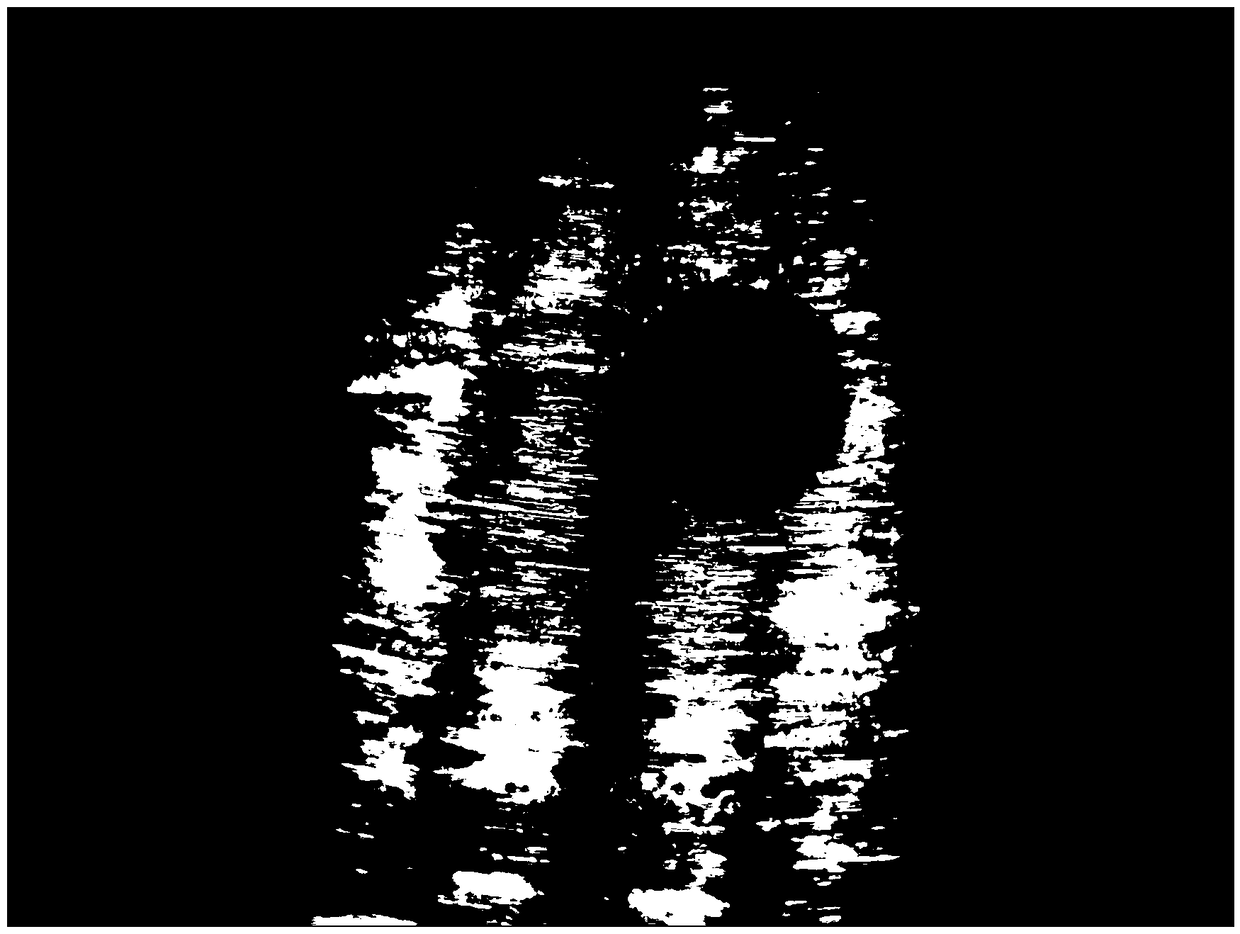

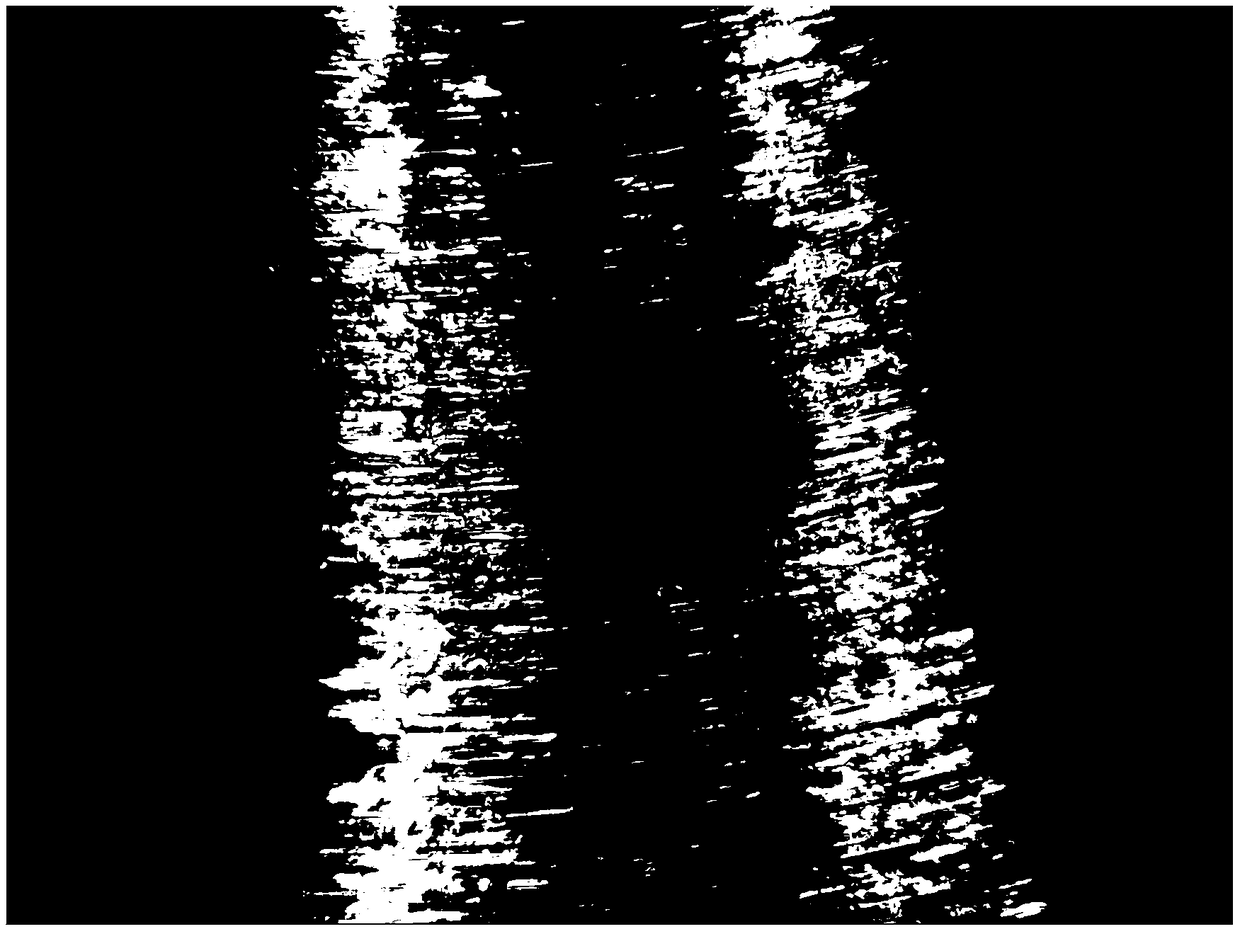

[0077] The electron microscope 1 is also connected with the image processing system 2, which is used to obtain the primary observation image R1 and the secondary observation image R2 of the micropore of the fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com