Measurement method for back-illuminated wafer crystal edge scribing depth

A back-illuminated, crystal-edge technology, applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve problems such as low measurement efficiency, improve product yield, speed up research and development progress, and support reliable data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

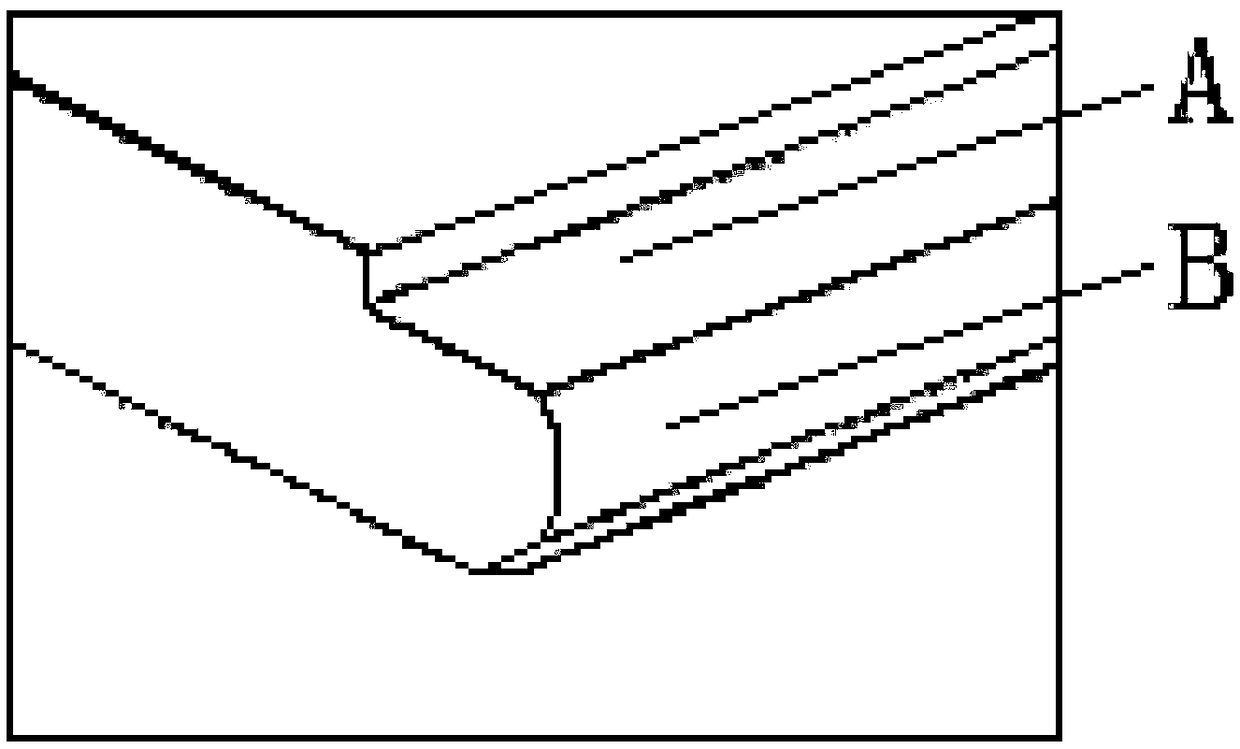

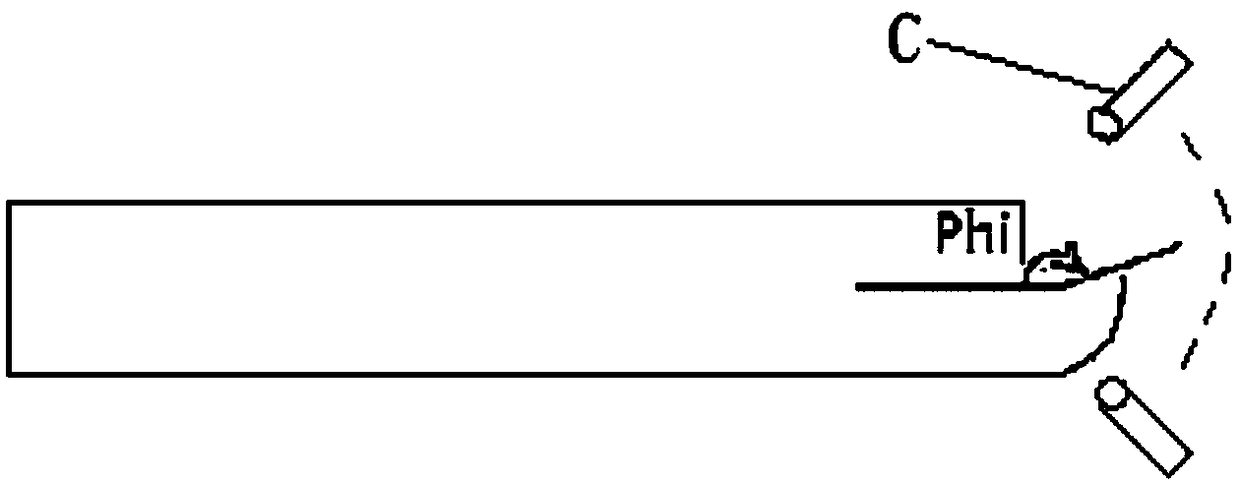

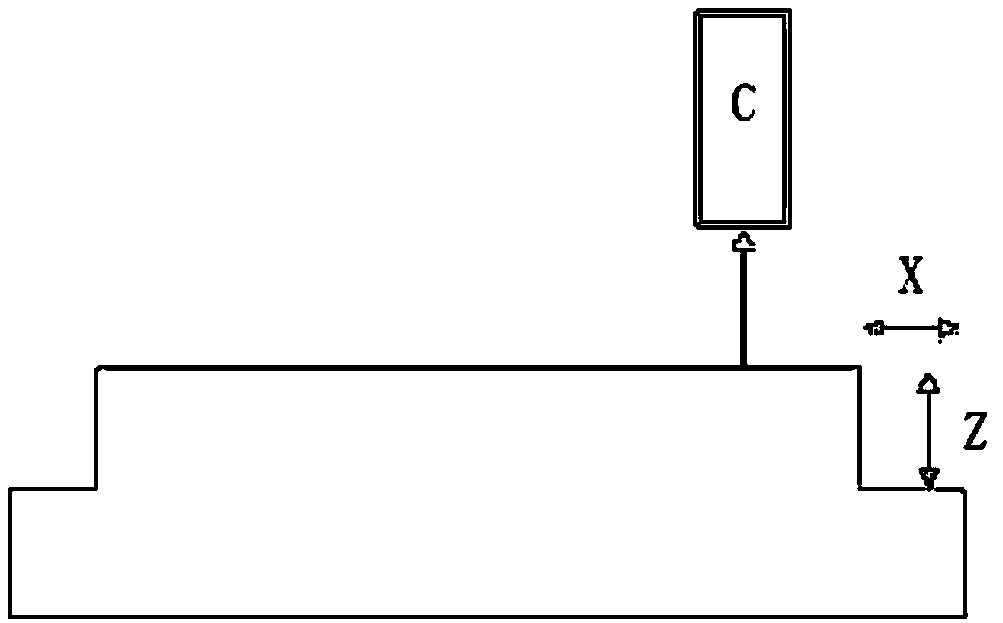

[0037] In the development stage of the back-illuminated wafer back-end process, a sample is selected, and a measurement program is established by using a wafer edge defect detector to scan the edge of the diced wafer to obtain the measurement data of the angular position of the dicing boundary line. Slice the sample and measure the actual scribing depth. The correction coefficient β in the elliptical crystal edge profile model is obtained by substituting the angular position data of the scribing boundary line measured by the crystal edge defect detector and the scribing depth obtained by slice analysis into the relationship function between the scribing depth and the angular position of the boundary line. And according to the correction coefficient β, and the wafer thickness T and other data, a complete elliptical crystal edge contour model corresponding relationship between the scribing depth and the angular position of the boundary line is established.

[0038] In the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com