Light-emitting diode micro-devices and display panels

A technology of light-emitting diodes and display panels, which is applied in semiconductor devices, electrical solid-state devices, electrical components, etc., can solve the problems of restricting the development of Micro-LEDs, low transfer efficiency, and waste of raw materials, so as to save raw materials and production costs and improve product quality. Yield rate and productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

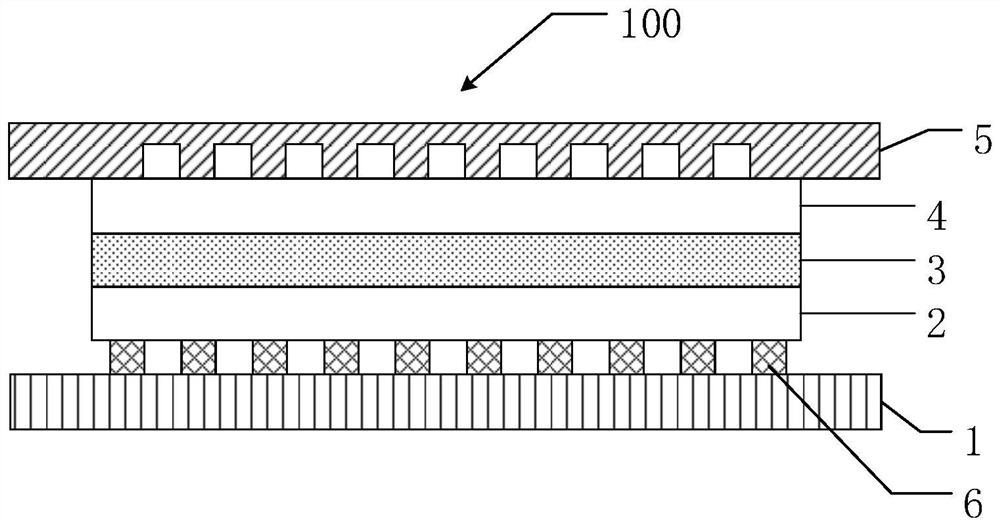

[0029] Such as figure 1 As shown, this embodiment provides an LED micro-device 100 , including a light emitting chip layer 3 , a first conductive layer 2 , a second conductive layer 4 , a first transparent substrate 1 and a transparent conductive layer 5 . The first conductive layer 2 is disposed on one surface of the light emitting chip layer 3 , and the second conductive layer 4 is disposed on the other surface of the light emitting chip layer 3 . The first conductive layer 2 covers the first transparent substrate 1 . The transparent conductive layer 5 is arranged on the second conductive layer 4 and is electrically connected to the second conductive layer 4. It is an indium tin oxide semiconductor transparent conductive film (ITO conductive glass). In order to reduce the crosstalk between pixels, transparent conductive The connecting surface of the layer 5 to the second conductive layer 4 is patterned.

[0030] The light-emitting wafer layer 3 is cut from a wafer with sev...

Embodiment 2

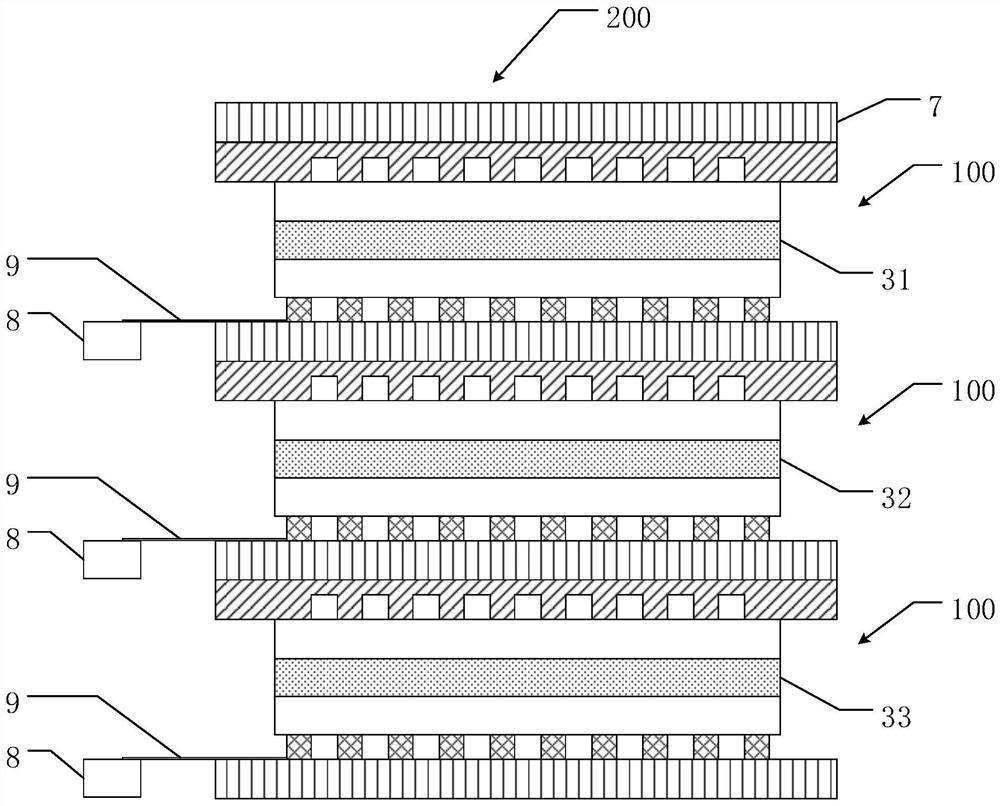

[0034] Such as figure 2 As mentioned above, this embodiment provides a display panel 200 including a group of LED micro-devices 100 as described in Embodiment 1, and all LED micro-devices 100 in each group are stacked up and down.

[0035] Each set of LED micro-device 100 includes LED micro-device 100 with red light-emitting wafer layer 31 , LED micro-device 100 with green light-emitting wafer layer 32 and LED micro-device 100 with blue light-emitting wafer layer 33 . The LED micro-device 100 with the green light-emitting wafer layer 32 is disposed on the LED micro-device 100 with the blue light-emitting wafer layer 33 . The LED micro-device 100 with the red light-emitting wafer layer 31 is disposed on the LED micro-device 100 with the green light-emitting wafer layer 32 .

[0036] The display panel 200 provided in this embodiment further includes a second transparent substrate 7 and three driving circuits 8 . The second transparent substrate 7 is a glass substrate, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com