Safe butt-joint power-on device for digitalized automatic assembly line

A technology of energizing device and assembly line, which is applied to the parts, coupling devices, circuits, etc. of the connecting device, can solve the problems of unsafe wiring method, long manual wiring time, mismatch of the whole line rhythm, etc., so as to avoid the rhythm mismatch. , the structure is simple, the effect of shortening the wiring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose of the invention, technical solutions and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods;

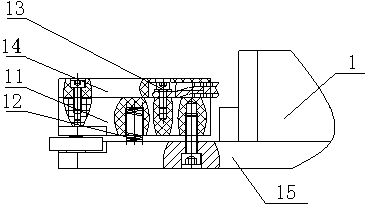

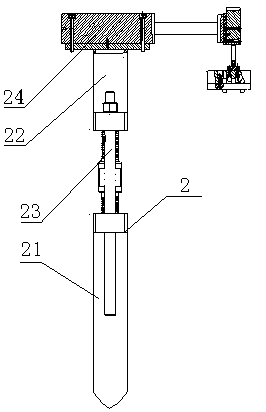

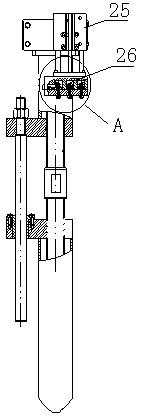

[0018] In the accompanying drawings: a safe butt-connecting device for a digital automatic assembly line, characterized in that it includes an insulating socket 1 and an insulating plug assembly 2; the insulating socket 1 includes a socket insulating mounting seat 11 arranged on a tray 15, A spring 12 is pre-embedded in the socket insulating mounting seat 11, and a copper conductive screw a13 wrapped with a wire is also arranged on the socket insulating mounting seat 11. Connection and fixation; the insulating plug assembly 2 includes a mounting column 21, the mounting column 21 is fixed on the ground through expansion bolts, the mounting frame 22 is arranged above the mounting column 21 and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com