Core-shell particles for use as filler for feeder compositions

A particle, core-shell technology applied in the field of core-shell particles used as fillers for riser materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

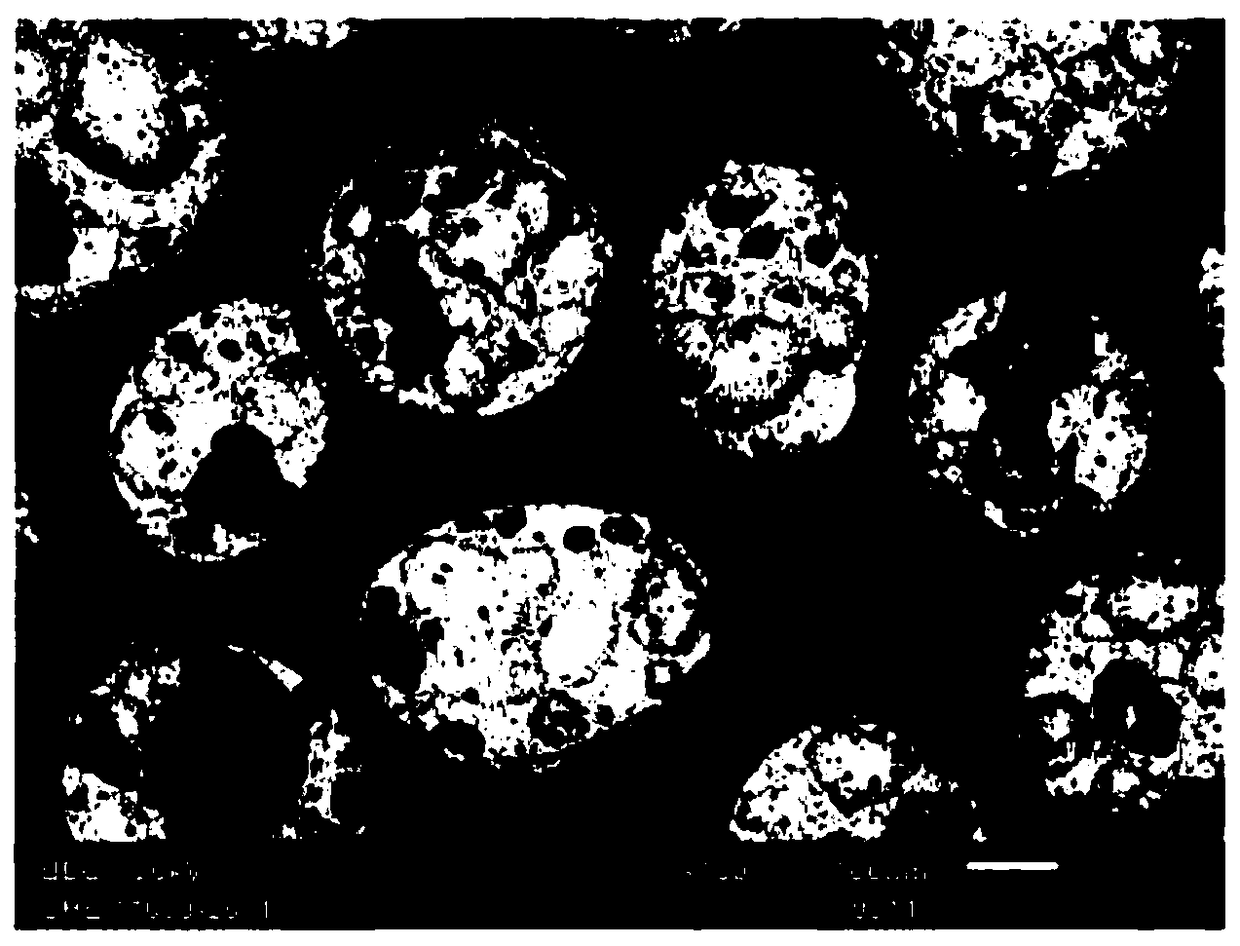

Embodiment 1

[0103] In a mixer of type BOSCH Profi 67, 664 g of foamed glass Liaver (standard particle size 0.1 mm to 0.3 mm; Liaver GmbH & Co. KG) were charged as carrier material and filled with 72 g of cold box binder (Hüttenes-Albertus AG). : benzyl ether resin based on Activator 6324 / Gas Resin 7241, the ratio of Activator 6324:Gas Resin 7241 is 1:1) wets evenly. 136 g of calcined kaolin (d50 value=1.4 μm, d10 value=0.4 μm, d90 value=7 μm) were added and the whole was mixed homogeneously. Finally, to harden the adhesive, approximately 0.5 mL of tert-amylamine was added. After a few seconds, the formed core-shell particles exist as loose material for further use.

Embodiment 2

[0105] In a mixer of type BOSCH Profi 67, 640 g of foamed glass Liaver (standard particle size 0.25 mm to 0.5 mm; Liaver GmbH & Co. KG) was charged as carrier material and filled with 72 g of cold box adhesive (Hüttenes-Albertus AG). : benzyl ether resin based on Activator 6324 / Gas Resin 7241, the ratio of Activator 6324:Gas Resin 7241 is 1:1) wets evenly. 160 g of calcined kaolin (d50 value=1.4 μm, d10 value=0.4 μm, d90 value=7 μm) were added and the whole was mixed homogeneously. Finally, to harden the adhesive, approximately 0.5 mL of tert-amylamine was added. After a few seconds, the formed core-shell particles exist as loose material for further use.

Embodiment 3

[0107] In a mixer of type BOSCH Profi 67, 664 g of Poraver foam glass (standard particle size 0.1-0.3; Dennert Poraver AG) was charged as carrier material and filled with 72 g of cold box binder (Hüttenes-Albertus company: based on activated The benzyl ether resin of agent 6324 / gas resin 7241, the ratio of activator 6324:gas resin 7241 is 1:1) wets evenly. 136 g of calcined kaolin (d50 value=1.4 μm, d10 value=0.4 μm, d90 value=7 μm) were added and the whole was mixed homogeneously. Finally, to harden the adhesive, approximately 0.5 mL of tert-amylamine was added. After a few seconds, the formed core-shell particles exist as loose material for further use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com