Method of manufacturing a rotor for a reluctance motor

A reluctance motor and rotor technology, applied in the manufacture of motor generators, stator/rotor bodies, synchronous motors for single-phase current, etc., can solve the problems of limited number of revolutions, weakened mechanical stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

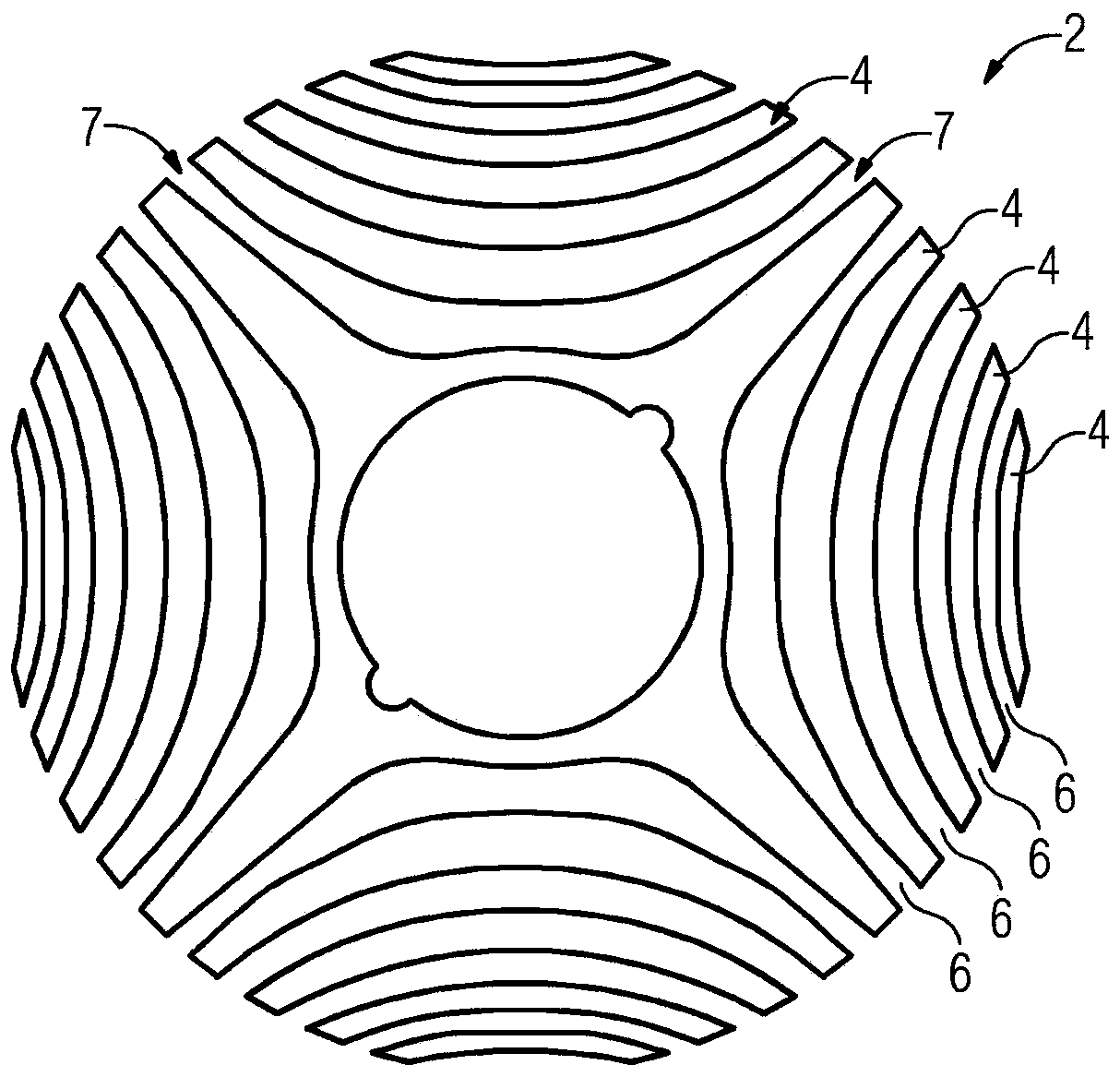

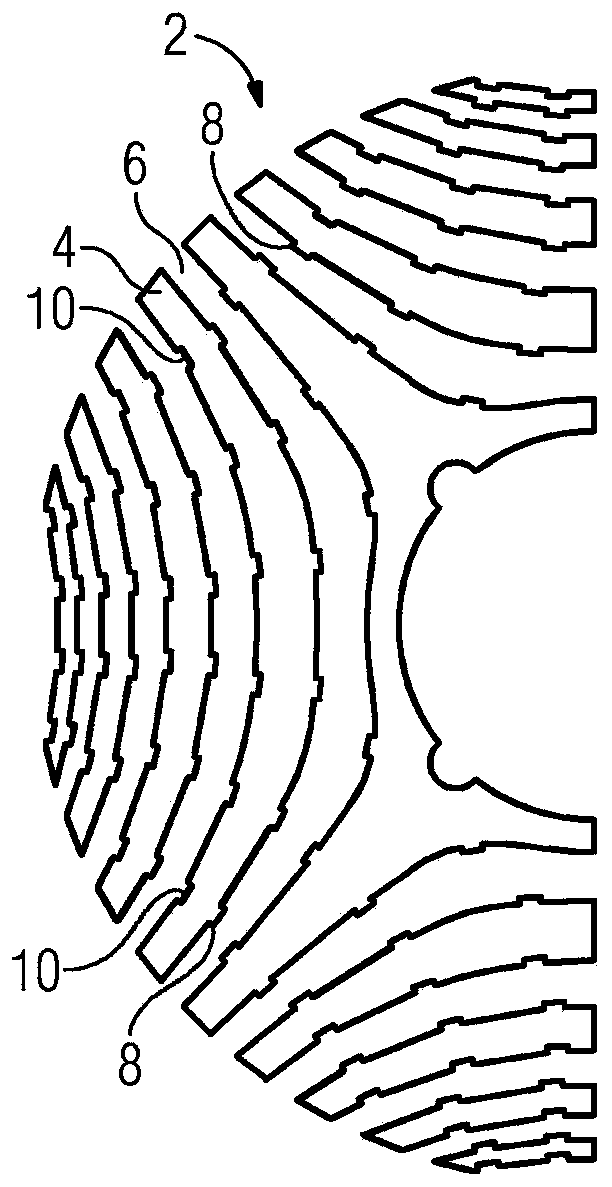

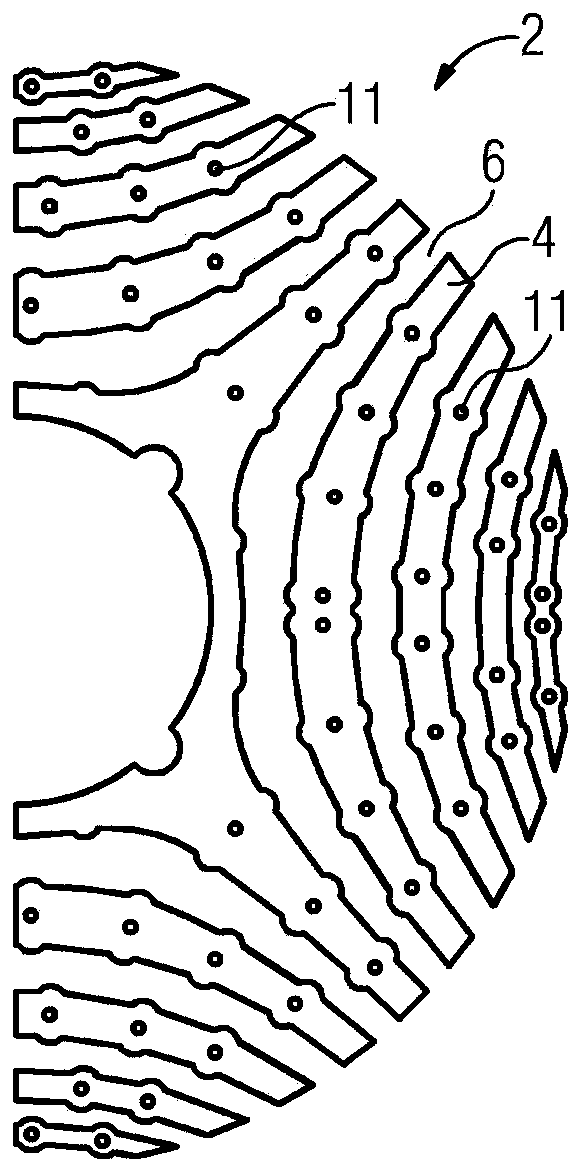

[0035] exist figure 1 Rotor laminations 2 of a rotor 12 produced according to the invention for a reluctance motor 18 , not shown in detail here, are shown in FIG. Such a reluctance motor 18 is Figure 7 Schematically shown in , the reluctance motor is an electric machine comprising a rotor 12 and a stator 20 . The reluctance motor 18 has a housing 22 in which the rotor 12 is rotatably mounted on a shaft 24 . The individual rotor laminations 2 are inserted one after the other on the shaft 24 and in this case form a single lamination stack. In operation, rotor 12 rotates about axis D. Furthermore, the stator 20 is located inside the housing 22 .

[0036] according to figure 1The rotor lamination 2 has a plurality of magnetic foils 4 made of a material with high magnetic permeability, eg iron. The lamellae are separated from one another by non-magnetic regions, which in the exemplary embodiment shown are arcuate grooves 6 , which are formed in particular by means of a tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com