Chalcogen-containing compound, method for preparing same, and thermoelectric element comprising same

A chalcogen and compound technology, which is applied in the field of chalcogen-containing compounds, their preparation and thermoelectric elements containing them, can solve the problems of inability to exhibit phase stability, low thermal conductivity thermoelectric characteristics, differential phase stability, etc. , to achieve the effect of excellent thermoelectric characteristics, excellent characteristics and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

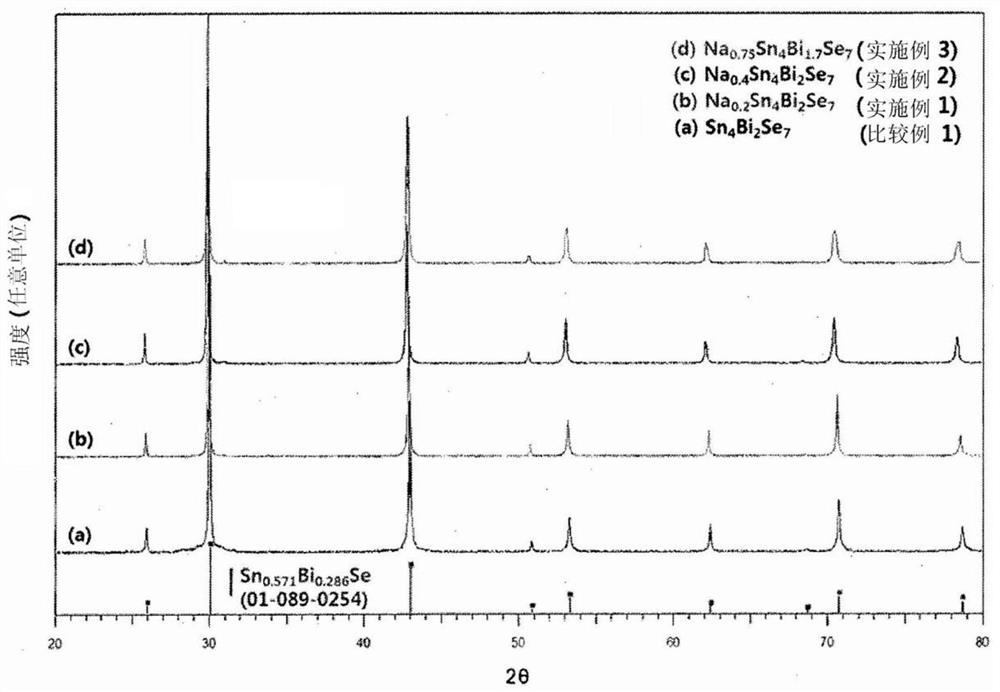

[0072] Example 1: Chalcogen-containing compound (Na 0.2 Sn 4 Bi 2 Se 7 ) preparation

[0073] Sn, Bi, Se and Na in a molar ratio of 4:2:6.9(7-0.1):0.1 in a glove box 2 The respective high-purity raw material powders of Se were weighed, placed in a carbon crucible, and then charged into a quartz tube. The inside of the quartz tube was evacuated and sealed. The raw materials were kept at a constant temperature in an electric furnace at 620°C for 24 hours.

[0074] Thereafter, the quartz tube in which the reaction was performed was cooled with water to obtain an ingot, which was finely ground into powder having a particle size of 75 μm or less, and sintered by spark plasma (SPS) at a temperature of 620° C. and a pressure of 50 MPa Sintering was performed for 10 minutes, thereby preparing a chalcogen-containing compound Na 0.2 Sn 4 Bi 2 Se 7 .

Embodiment 2

[0075] Example 2: Chalcogen-containing compound (Na 0.4 Sn 4 Bi 2 Se 7 ) preparation

[0076] The chalcogen-containing compound Na was prepared by the same method as in Example 1 0.4 Sn 4 Bi 2 Se 7 , the difference is that Sn, Bi, Se and Na 2 The respective high purity raw material powders of Se were mixed in a glove box in a molar ratio of 4:2:6.8(7-0.2):0.2.

Embodiment 3

[0077] Example 3: Chalcogen-containing compound (Na 0.75 Sn 4 Bi 1.7 Se 7 ) preparation

[0078] The chalcogen-containing compound Na was prepared by the same method as in Example 1 0.75 Sn 4 Bi 1.7 Se 7 , the difference is that Sn, Bi, Se and Na 2 The respective high purity raw material powders of Se were mixed in a glove box at a molar ratio of 4:1.7:6.625(7-0.375):0.375.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com