Large manipulator with weight-optimized articulated mast

A technology of manipulators and masts, which is applied in the direction of manipulators, program-controlled manipulators, cranes, etc., can solve problems such as complex production technology, and achieve the effect of simple weight reduction, weight reduction, and low material thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

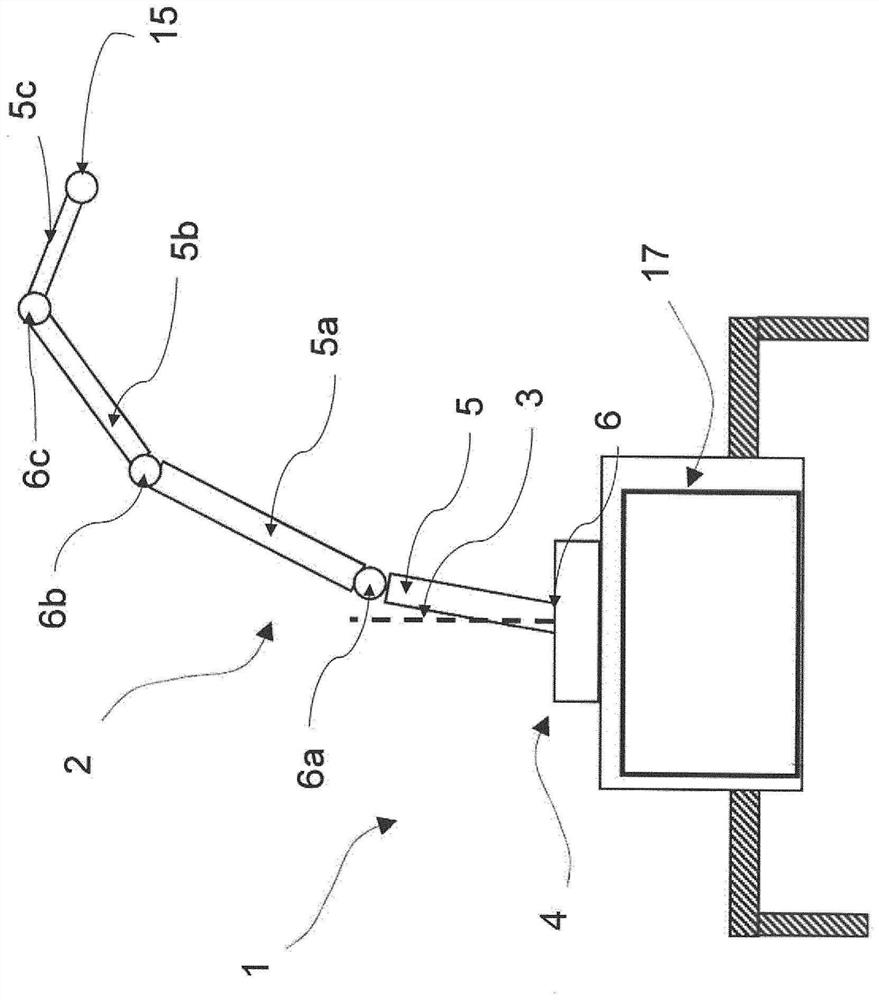

[0029] according to figure 1 The illustration in the figure shows a large manipulator 1 for a vehicle-mounted concrete pump with a folding articulated mast 2 with a turntable 4 rotatable about a vertical axis 3 and a plurality of mast sections 5, 5a, 5b, 5c. Each mast section 5, 5a, 5b, 5c can be driven at the hinged joint 6, 6a, 6b, 6c relative to the adjacent mast section 5, 5a, 5b, 5c or the turntable 4 around the hinge axis by means of a drive The unit (not shown) pivots. By means of the large manipulator 1, the fluid concrete is conveyed from the concrete pump 17 to the top of the mast 15 through a concrete supply line (not shown), wherein the concrete supply line terminates in a terminal hose (not shown), so that when passing through this vehicle-mounted concrete When pumping concrete, large distances and heights can be bridged with the aid of the large manipulator 1 .

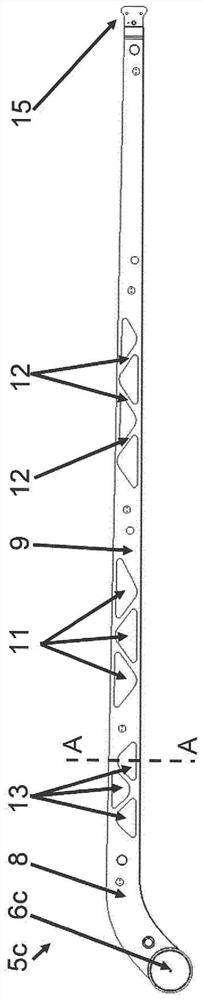

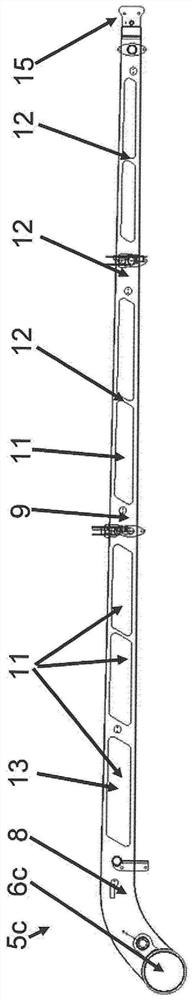

[0030] figure 2 The last mast section 5c forming the mast top 15 is schematically shown, which ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com