Jet extractor

An extractor and jet technology, which is applied in the field of jet extractors, can solve the problems of constant operation, cumbersome water adding process to the extractor, cumbersome process of assembling, fixing, disassembling and removing the jet bottle and the sample storage bottle, and simplifies the process of adding water. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

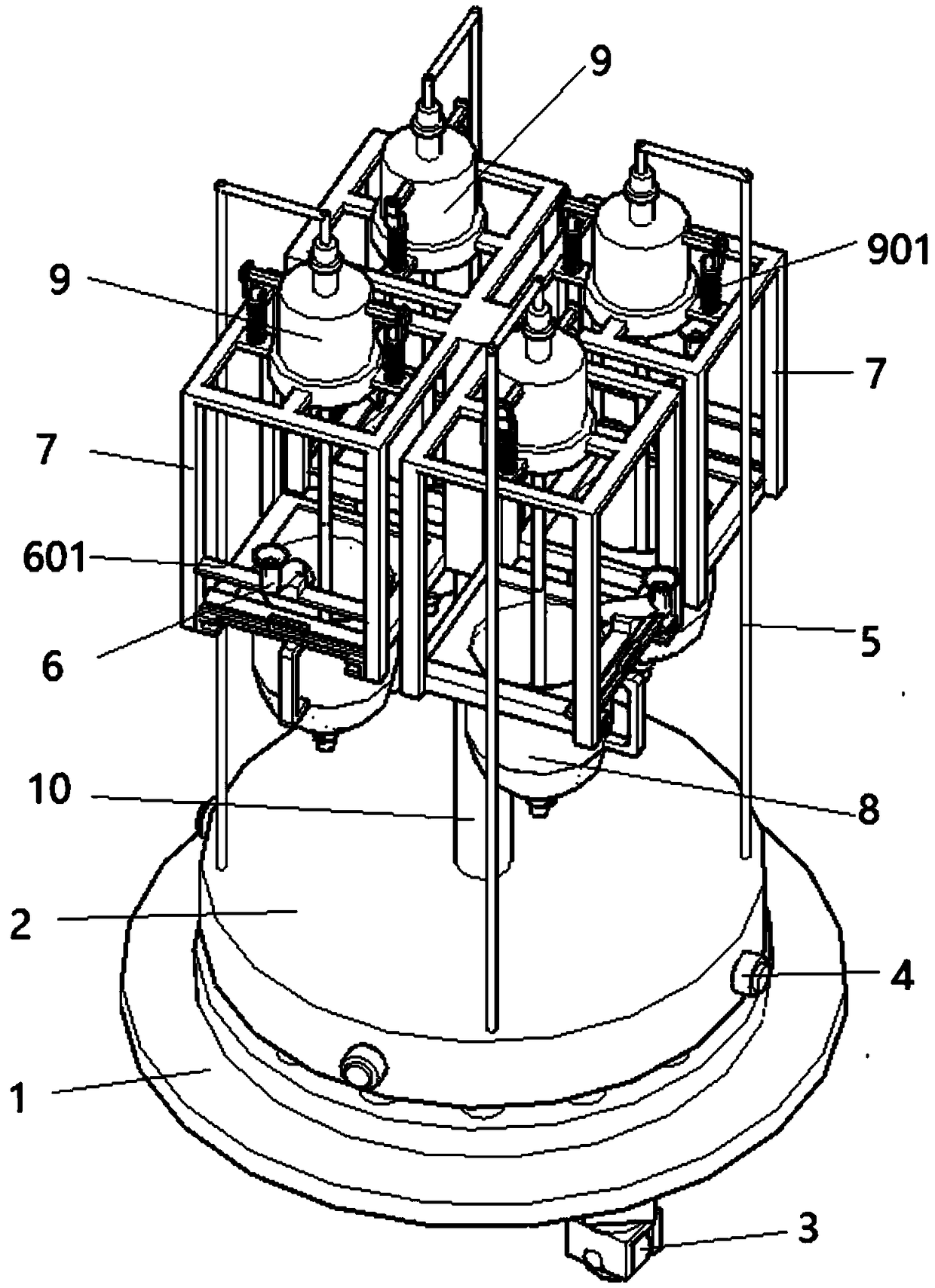

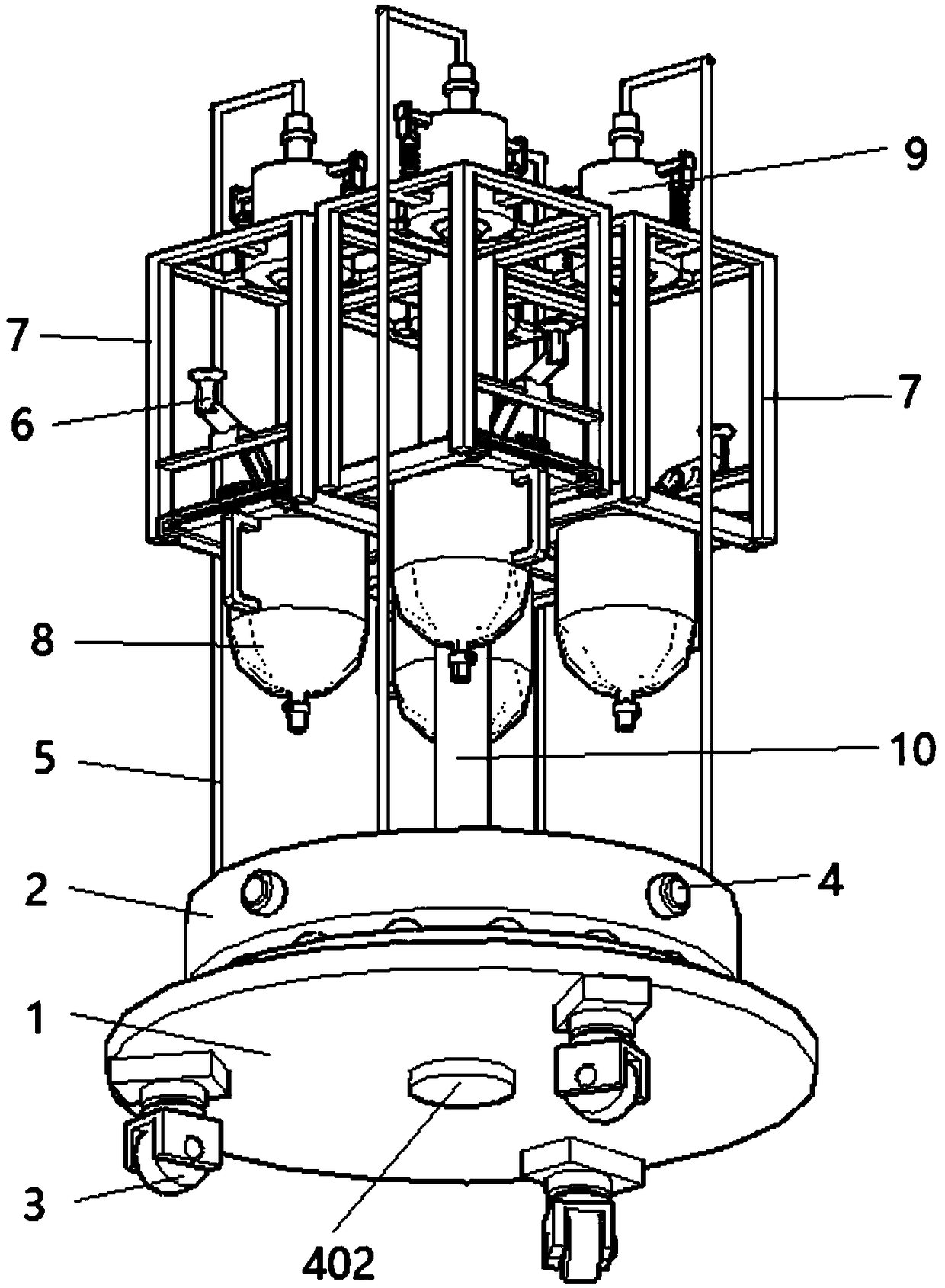

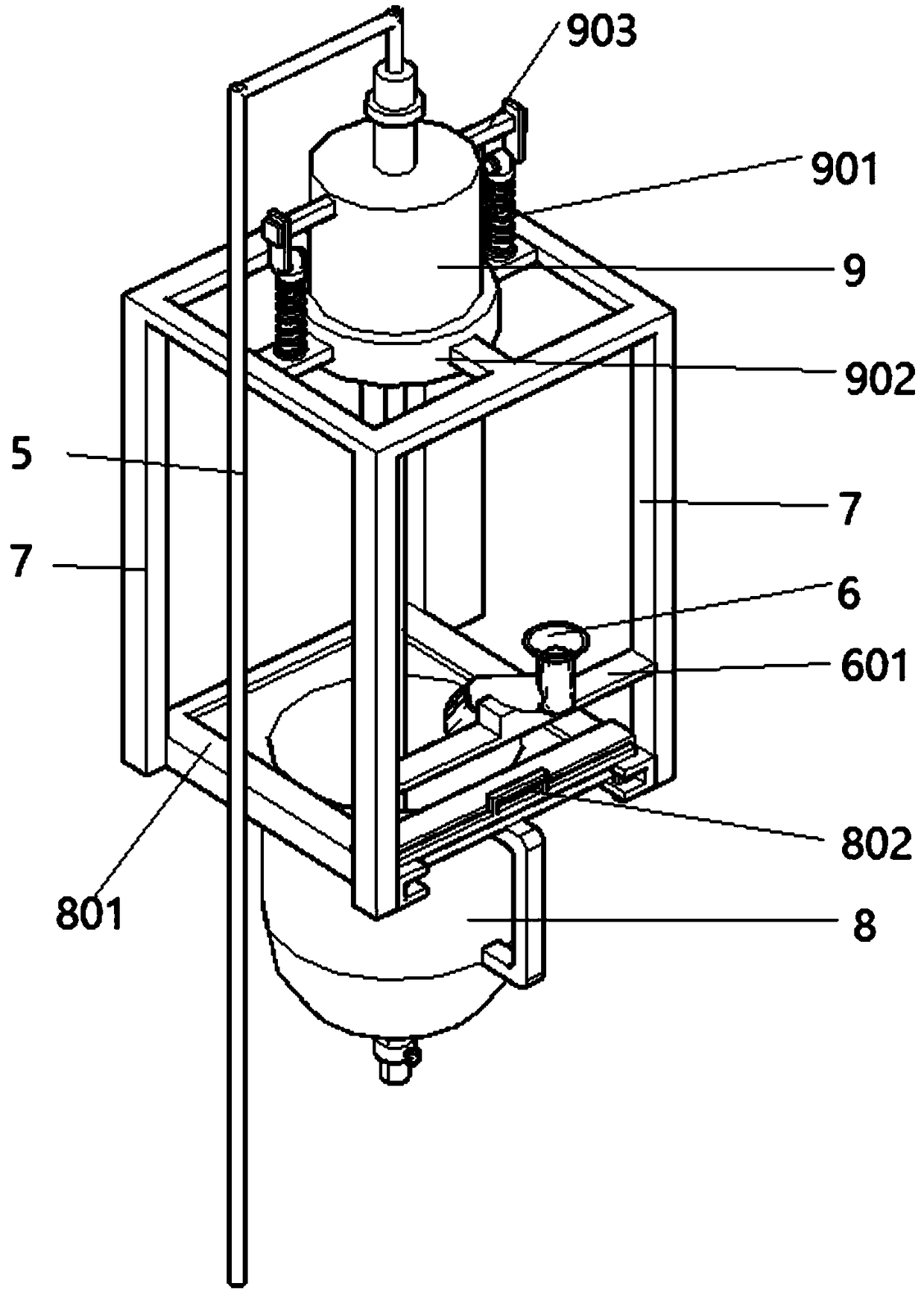

[0027] as attached figure 1 to attach figure 2 Shown:

[0028]The invention provides a jet extractor, which includes a base 1, an electrical component box 2, a charging port 201, a roller 3, a start button 4, an insertion rod 401, a limit baffle 402, an air pipe 5, a water filling funnel 6, and a funnel support horizontal Plate 601, support rod 7, sample storage cup 8, slide rail 801, limit plate 802, jet bottle 9, tension spring 901, support ring 902, limit rod 903, clamping plate 904 and center support rod 10, The base 1 is arranged in a circle, and its bottom is welded and fixed in an annular array with three rollers 3, and the three rollers 3 are universal wheels with brake devices; the electrical component box 2 is hollowed out in a cylindrical shape as a whole structure, a central support rod 10 is supported at the center of the top end face, and a plunger 401 is suspended at the center of the bottom face, and a limit baffle 402 is fixedly connected to the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com