A kind of high-efficiency chopping mechanism and chopping method

A tooth-chopping and high-efficiency technology, which is applied to the high-efficiency tooth-chopping mechanism and the field of tooth-chopping, can solve the problems of low working efficiency, low durability and high working pressure of the tooth-chopping machine, so as to improve the stability of use, the scope of application and the working pressure. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

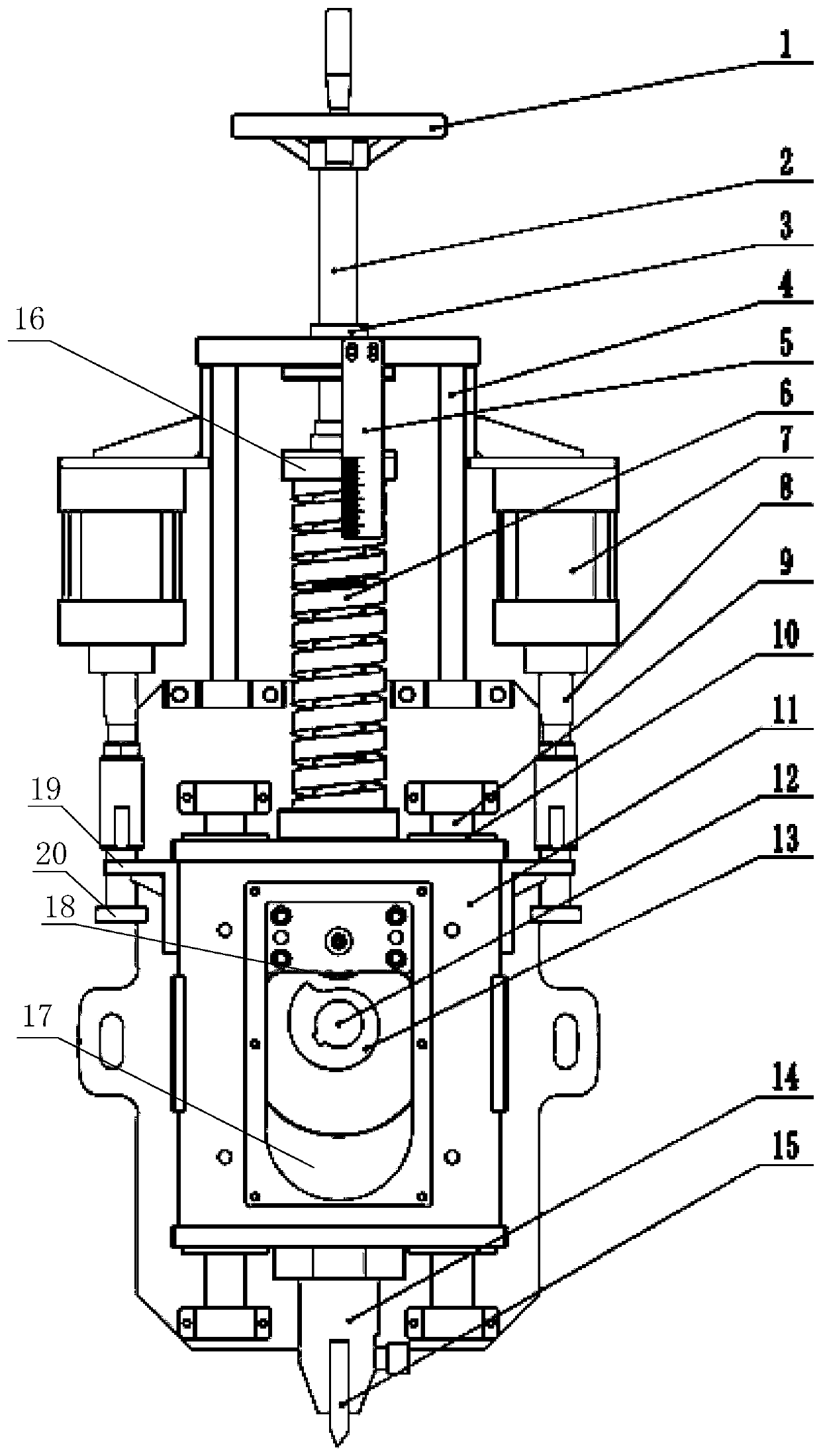

[0031] like figure 1 A kind of high-efficiency tooth chopping mechanism shown comprises a chopping knife 15, a clamping device 14 for clamping the chopping knife 15, and the chopping knife 15 is vertically downward, and the clamping device 14 and the chopping tooth ram 11 Fixedly connected, a bracket 4 is arranged above the tooth chopping ram 11, and a screw rod 2 passing through the bracket 4 is also included, a nut 3 is arranged on the top of the bracket 4, and the screw rod 2 passes through the nut 3, so The bottom end of the screw mandrel 2 is connected to the pressing plate 16 located in the bracket 4, a spring 6 is arranged between the top of the tooth chopping ram 11 and the bottom of the pressing plate 16, and a spring 6 is also included for driving the tooth chopping ram 11. The first linear drive mechanism for up and down motion.

Embodiment 2

[0033] On the basis of Example 1, such as figure 1 As shown, the first linear drive mechanism includes a through hole 17 opened inside the tooth chopping ram 11, a protrusion 18 protruding downward is provided on the inner top surface of the through hole 17, and a protrusion 18 is arranged below the protrusion 18 and located in the through hole. The cam 13 in the hole 17 is matched with the protrusion 18, and the cam 13 is driven by a motor to rotate. The output end of the motor drives the rotating shaft 12 to rotate through a shaft coupling, and the rotating shaft 12 is connected with the cam 13 by a flat key. It also includes a marking ruler 5 fixed on the bracket 4 , the said marking ruler 5 faces the top of the spring 6 , and the scale direction of the marking ruler 5 is parallel to the axis of the spring 6 . The hand wheel 1 is fixed on the top of the screw mandrel 2 .

Embodiment 3

[0035] On the basis of Embodiment 2, a second linear drive mechanism is also included, the driving end of the second linear drive mechanism is connected to the drawbar 8, and the driving direction of the second linear drive mechanism and the axis of the drawbar 8 are all parallel On the axis of the spring 6, the traction rod 8 is used to pull the chopping tooth ram 11 to move. The outer surface of the chopping tooth ram 11 is fixedly connected to the limit plate 19, the draw bar 8 passes through the limit plate 19 from top to bottom, and the bottom end of the draw bar 8 is fixed with a limit block 20, so The limiting block 20 cannot pass through the limiting plate 19. A sliding bearing 10 is arranged on the top of the tooth chopping ram 11 , and the sliding shaft 9 is inserted into the tooth chopping ram 11 through the sliding bearing 10 . The second linear drive mechanism is an air cylinder 7 fixed outside the bracket 4 .

[0036] A method for chopping teeth, comprising the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com