Method for laser-stirring friction composite welding of large-thickness plate

A friction stir and hybrid welding technology, used in laser welding equipment, welding equipment, non-electric welding equipment and other directions, can solve the problems of poor weld formability, easy formation of collapse and root leakage, etc., to improve surface tension and promote force balance , the effect of inhibiting collapse and root leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

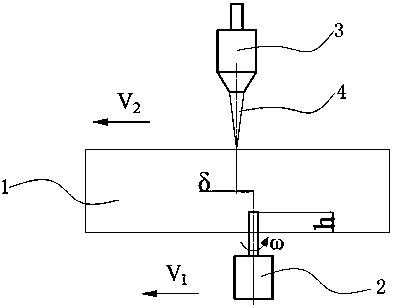

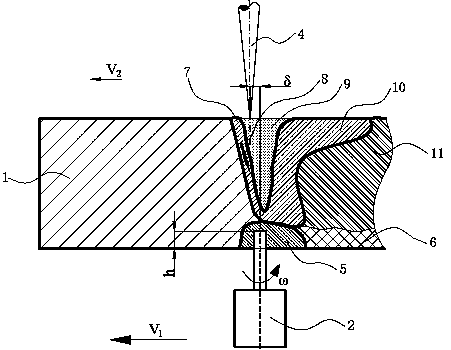

[0025] The following will be combined with the attached figure 1 and figure 2 Specific embodiments of the present invention will be described in detail.

[0026] In this embodiment, a method for laser-friction stir hybrid welding of large-thickness plates includes the following steps.

[0027] Step 1: Provide the workpiece 1 plate to be welded, which is made of aluminum alloy and has a thickness of 15 mm to 25 mm. Before welding, use an organic solvent to remove surface oil, impurities, etc.

[0028] Step 2: Arrange the friction stir processing head 2 on the back of the plate to be welded 1 .

[0029] Step 3: arrange the laser welding head 3 on the front surface of the workpiece 1 to be welded.

[0030] Step 4: The high-energy laser beam 4 focused by the laser welding head 3 irradiates the upper surface of the workpiece 1 to be welded and moves along the welding direction.

[0031] The power of the high-energy laser beam 4 is greater than 15 kW; the moving speed of the la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com