Self-adaptation grain outer wall face grinding device

A self-adaptive, outer wall surface technology, applied in the direction of surface polishing machine tools, grinding machine parts, grinding/polishing equipment, etc., can solve problems such as occupational hazards, low grinding efficiency, inconsistent quality, etc., and achieve continuous long-term grinding , Grinding time saving, improving the effect of grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

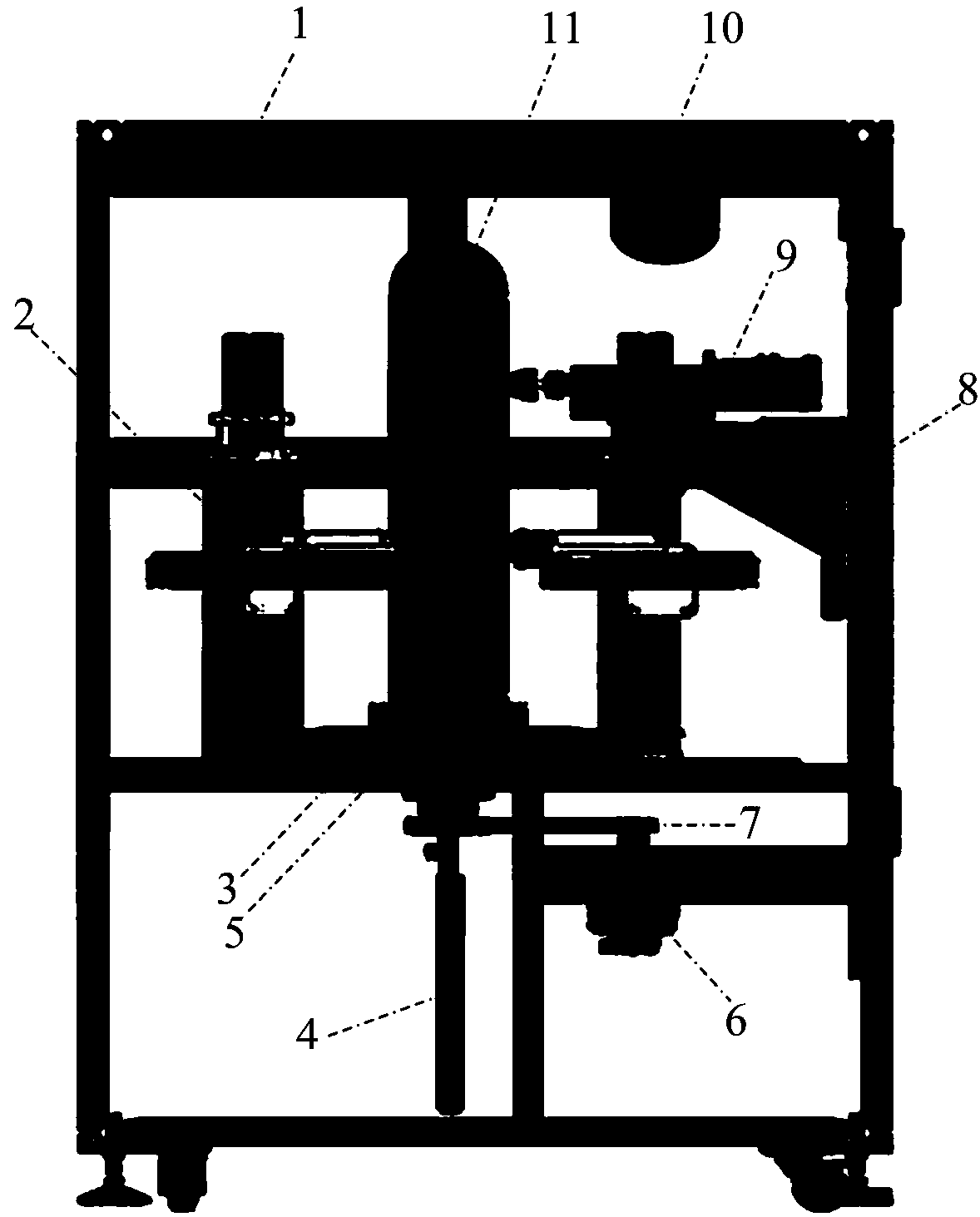

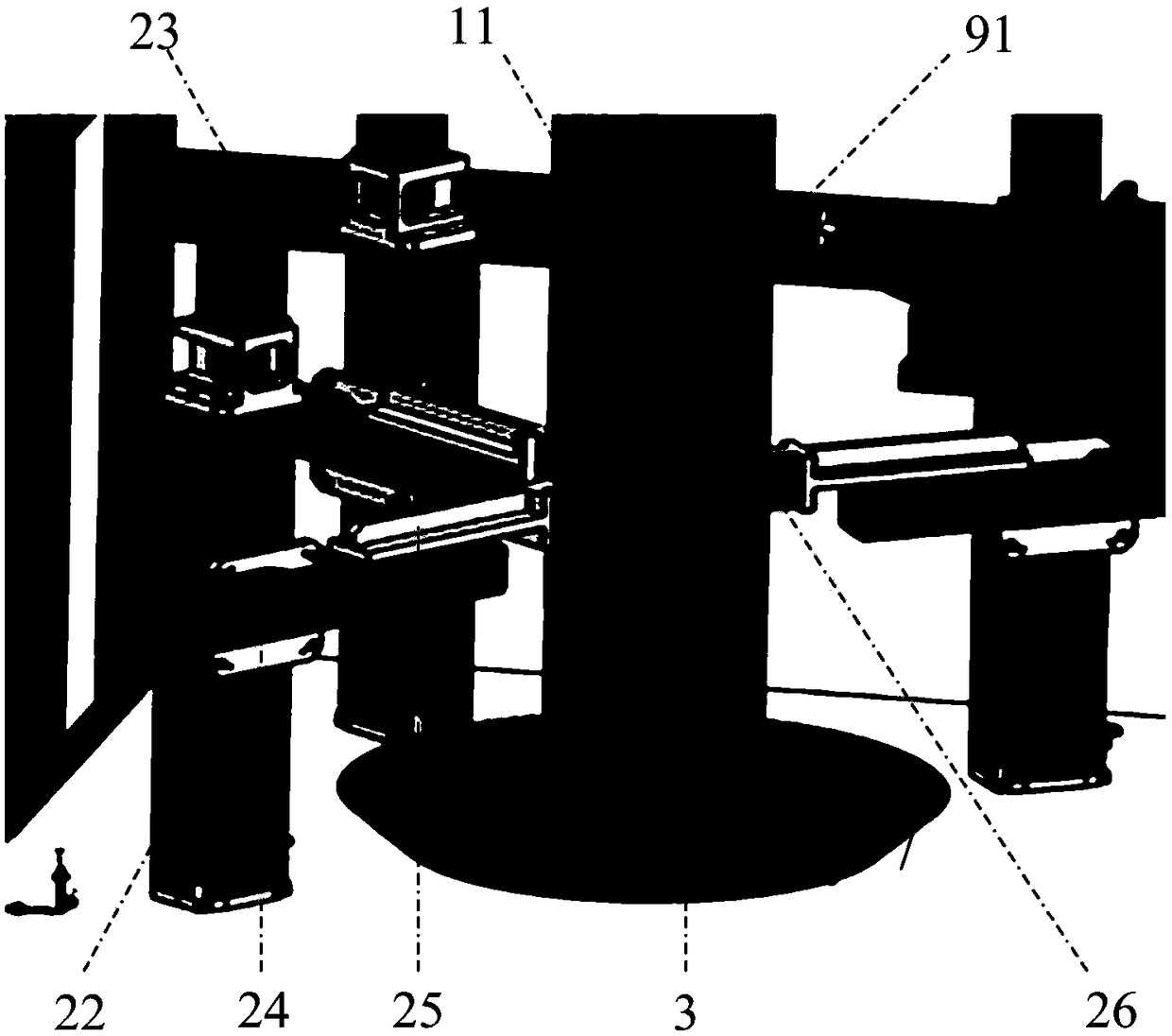

[0017] figure 1 Shown is a self-adaptive grinding device for the outer wall of the powder column, including a frame 1, a centering mechanism 2, a core seat 3, a vacuum tube 4, a material receiving tray 5, a rotating motor 6, a pulley 7, a lifting guide rail 8, a grinding Mechanism 9, explosion-proof camera 10.

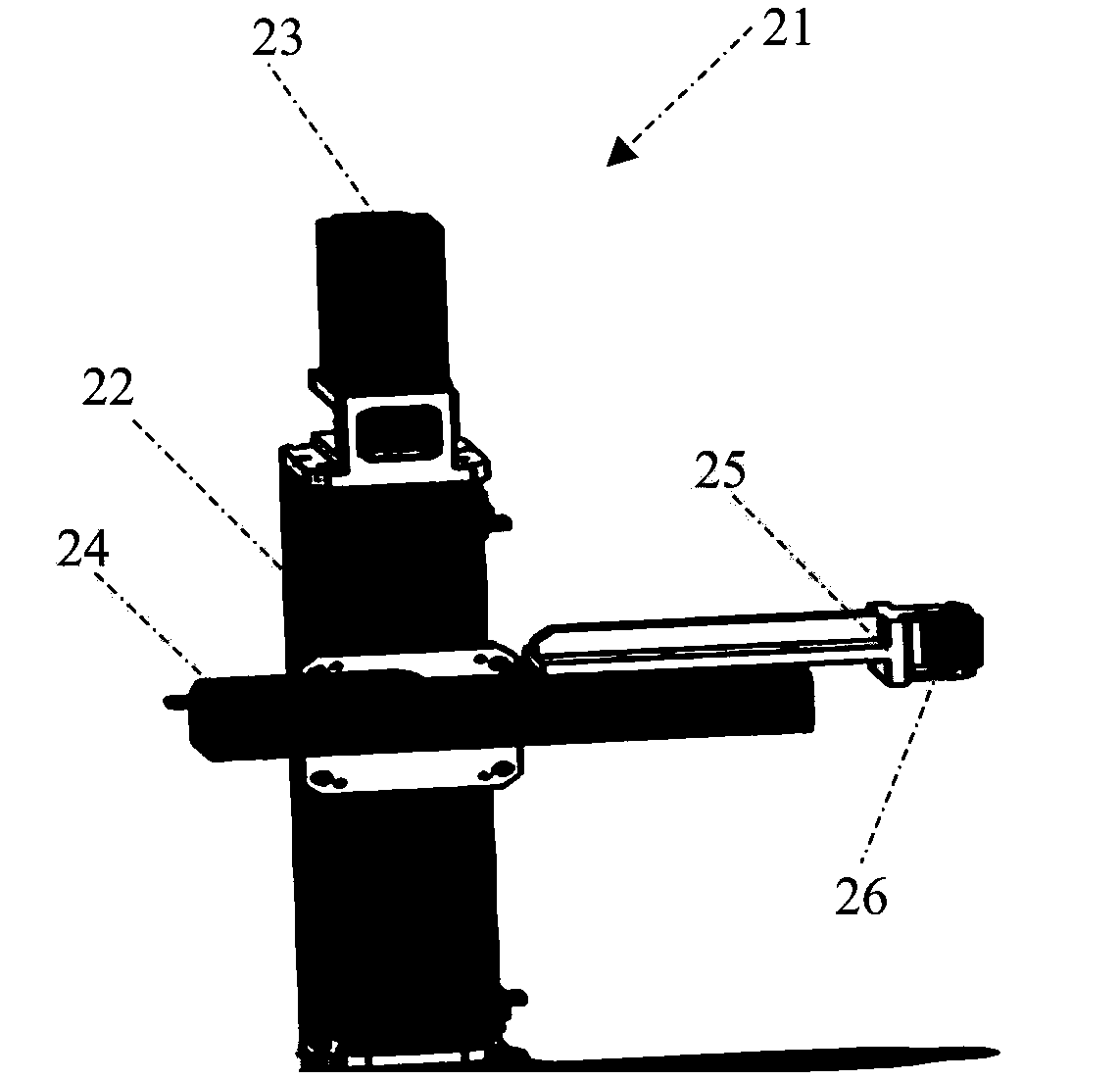

[0018] Described centering mechanism 2 is made up of three groups of centering arms 21, and centering arm 21 comprises vertical slide rail 22, screw motor 23, horizontal slide rail 24, horizontal arm 25, centering roller 26, as figure 2 shown.

[0019] The centering roller 26 is installed on one end of the horizontal arm 25, and the other end of the horizontal arm 25 can slide freely on the horizontal slide rail 24. When the horizontal arm 25 slides, the direction is the radial direction of the mold core seat 3, and the lead screw mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com