Battery Management System and Electric Vehicle

A battery management system and battery cell technology, applied in electric vehicles, battery/fuel cell control devices, vehicle components, etc., can solve problems such as difficulty in adapting to battery management system requirements, achieve reliability and safety, and score accurately , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described below in conjunction with the accompanying drawings.

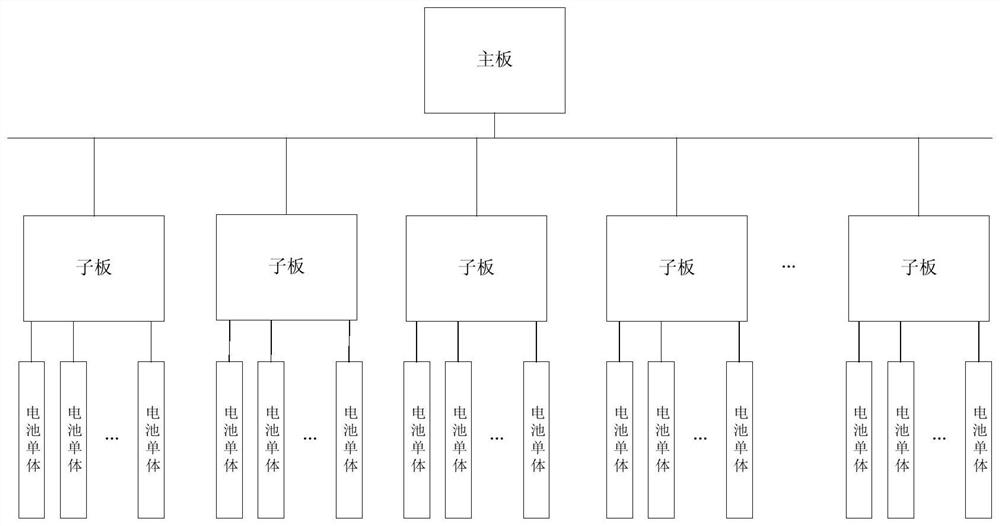

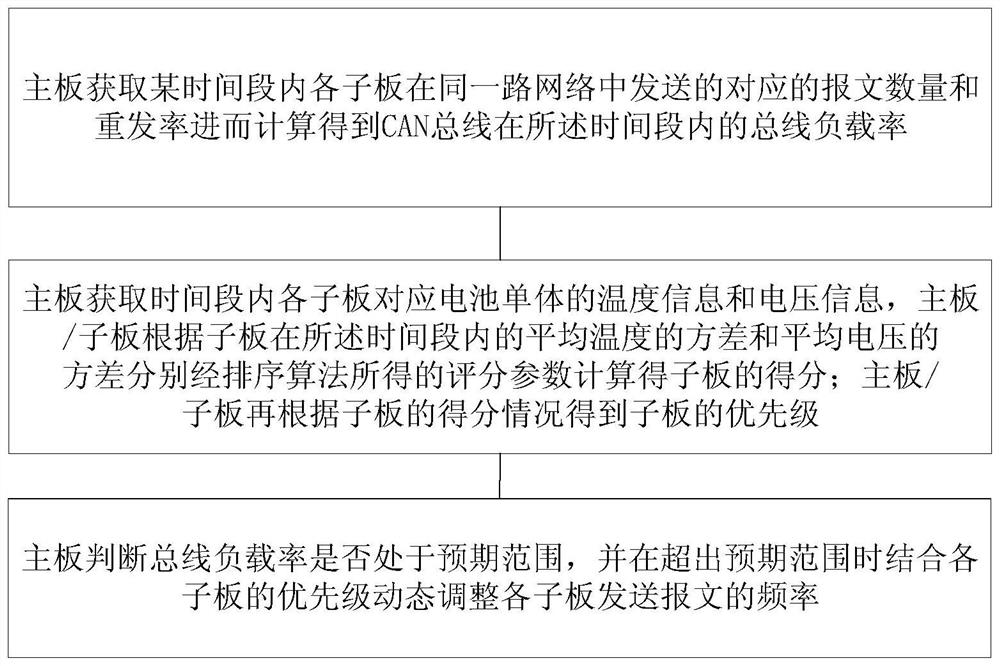

[0037] to combine figure 1 and figure 2 As shown, they are respectively a structural block diagram and a working principle diagram of a battery management system for an electric vehicle provided by the present invention. The battery management system includes several battery cells, a main board and several sub-boards, and each sub-board corresponds to a plurality of battery cells. monomer. Such as figure 1 It can be understood that the battery cells are divided into a plurality of battery cell groups, each sub-board corresponds to a battery cell group, and each battery cell group includes the plurality of battery cells. Each sub-board interacts with the main board through the CAN bus, figure 2 It can also be referred to as a communication flowchart between the main board and the sub-board. The main board obtains the corresponding number of messages and the retransmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com