A mold platform traverse train set with a synchronous control device and its use method

A technology of synchronous control and traversing of vehicles, applied in the directions of transportation and packaging, mechanical conveyors, conveyors, etc., can solve the problems of body width and self-weight, etc., and achieve low civil engineering workload, low cost and high layout flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

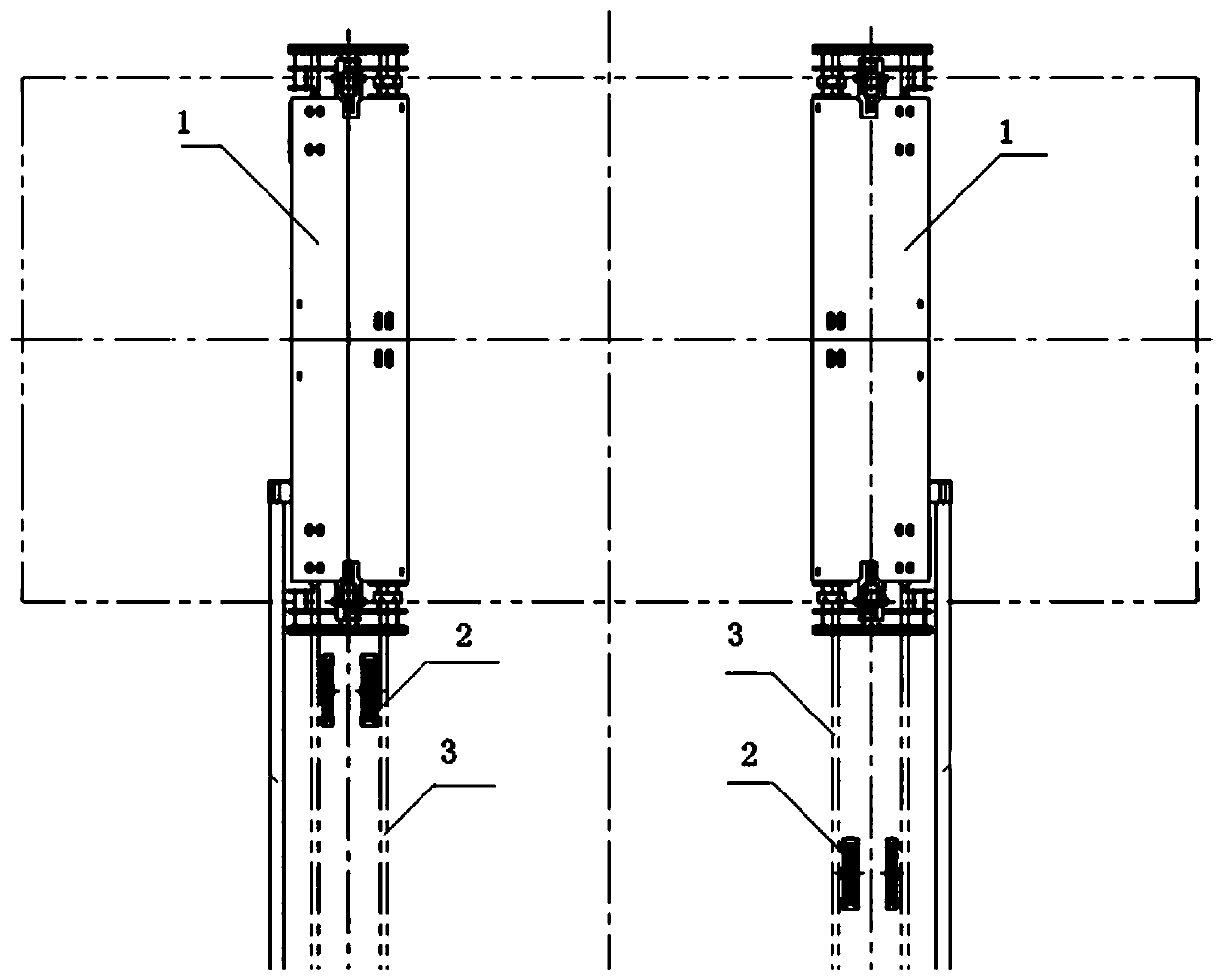

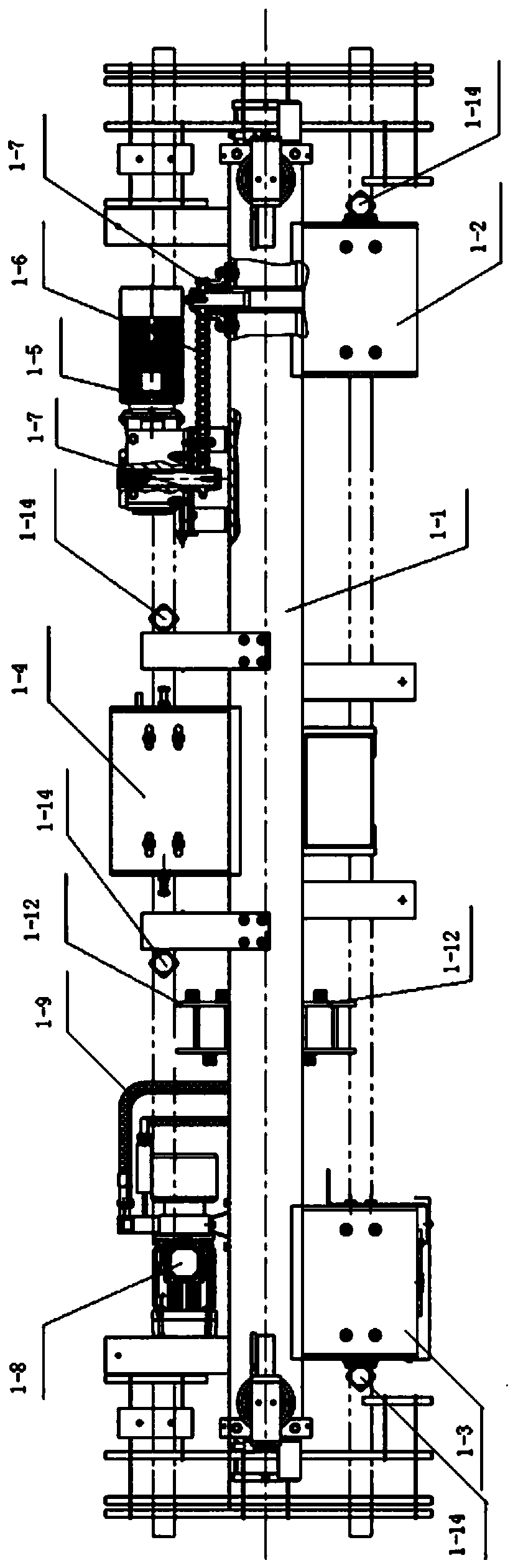

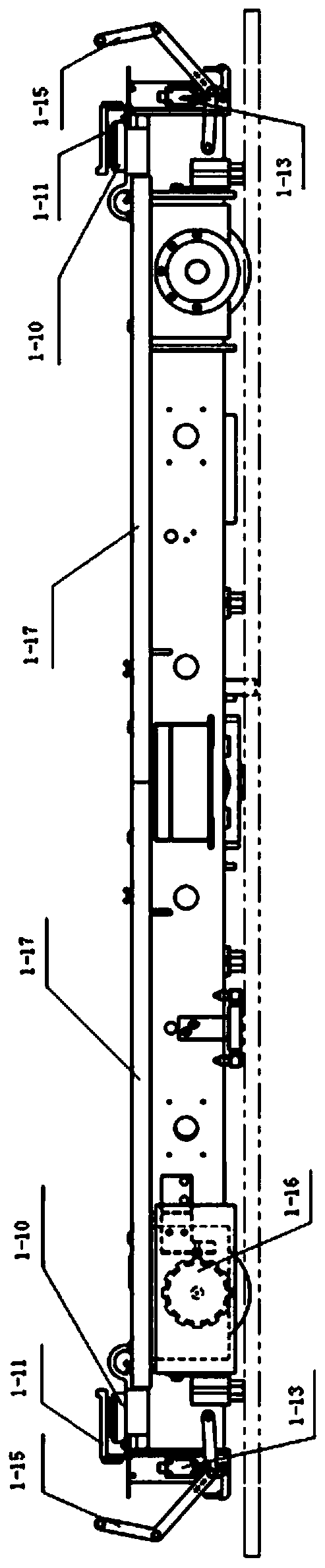

[0028] Such as Figure 1-4 As shown, a mold platform traversing vehicle group with a synchronous control device includes a pair of traversing vehicles 1, a control system, a ground track 3 and a positioning seat 2, and the traversing vehicle 1 includes a vehicle body 1-1, driving wheels Box 1-2, driven wheel box 1-3, middle wheel box 1-4, gear motor 1-5, hydraulic power unit 1-8, hydraulic cylinder 1-10, top plate 1-11, positioning proximity switch 1-12, Anti-collision barrier 1-15, limit switch 1-13, track clearing block 1-14, speedometer 1-16 and protective plate 1-17, driving wheel box 1-2 and driven wheel box 1-3 are set respectively At both ends of the same side of the vehicle body 1-1, the wheels in the driving wheel box 1-2 and the driven wheel box 1-3 have double rims, and the middle wheel box 1-4 is arranged on the body 1-1 In the middle position on the other side, the wheel in the middle wheel box 1-4 has no rim; The output shaft of the motor 1-5 and the wheel shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com