Self-compacting concrete and preparation method thereof

A technology for self-compacting concrete and mixed sand, applied in the field of concrete, can solve the problems of increased cracking risk, increased concrete shrinkage, increased amount of cementitious materials, etc., and achieves the effect of saving transportation costs and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

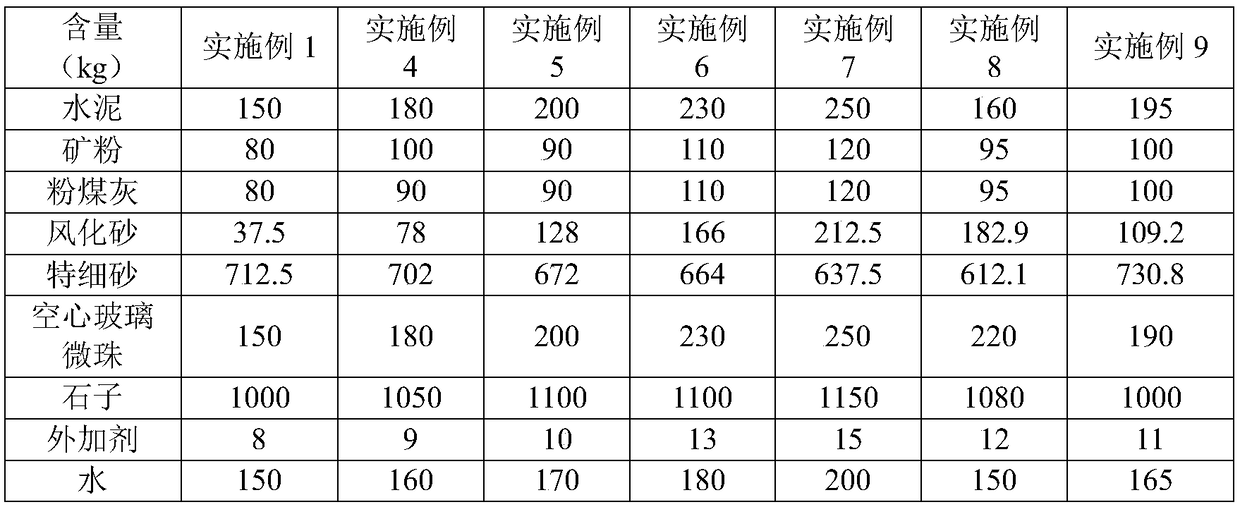

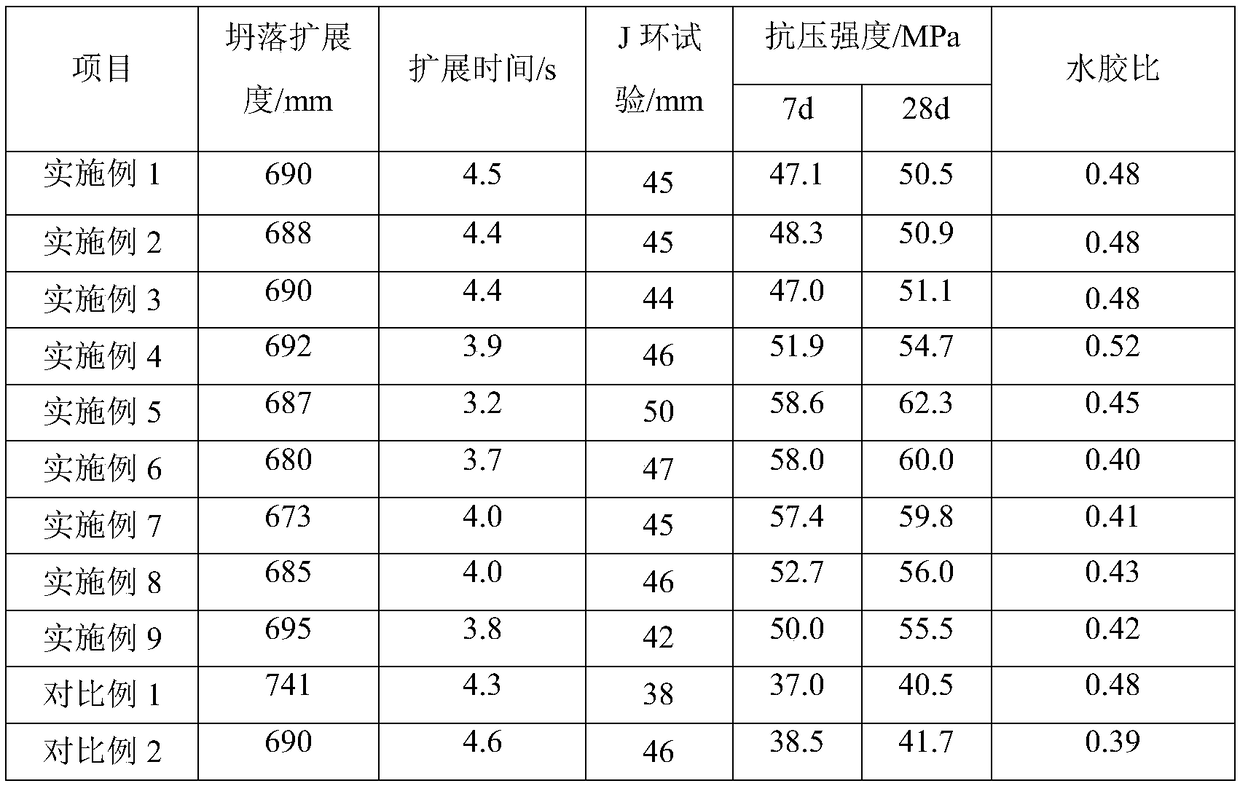

Examples

Embodiment 1

[0034] According to the addition amount of each raw material in Table 1, cement, mineral powder and fly ash were added to a mechanical mixer and mixed dry for 2 minutes to obtain mixture A; weathered sand and ultrafine sand with a fineness modulus of 1.0 , stones, admixtures and water were added to another mixer and mixed for 1 minute to obtain Mixture B; Export Mixture A from the mixer and introduced into another mixer to mix with Mixture B, after stirring for 2 minutes, add the hollow glass micro The beads were mixed and stirred at a speed of 30r / min for 1.5 minutes to obtain self-compacting concrete.

Embodiment 2

[0036]According to the amount of each raw material added in Example 1, cement, mineral powder and fly ash were added to a mechanical mixer and mixed for 2 minutes to obtain mixture A; weathered sand, fineness modulus of 1.1 Add sand, stones, admixtures and water into another mixer and mix for 1 minute to obtain Mixture B; export Mixture A from the mixer and import it into another mixer to mix with Mixture B, stir for 2 minutes and then add hollow glass The microbeads were mixed and stirred at a speed of 40r / min for 1 minute to obtain self-compacting concrete.

Embodiment 3

[0038] According to the addition amount of each raw material in Example 1, cement, slag powder and fly ash were added to a mechanical mixer and mixed and dry mixed for 2 minutes to obtain mixture A; weathered sand, fineness modulus of 1.2 Add sand, stones, admixtures and water into another mixer and mix for 1 minute to obtain Mixture B; export Mixture A from the mixer and import it into another mixer to mix with Mixture B, stir for 2 minutes and then add hollow glass The microbeads were mixed and stirred at a speed of 50r / min for 0.5 minutes to obtain self-compacting concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com