Rubber material

A rubber material and rubber technology, applied in the field of rubber materials, can solve problems such as ozone resistance, poor weather resistance, difficulty in meeting automotive technical requirements, and natural rubber materials are not resistant to high temperature, thermal oxygen aging, etc., to prolong service life and resist vulcanization The effect of returning to the original ability and improving the ability of high temperature thermal oxygen aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following specific embodiments further illustrate the present invention.

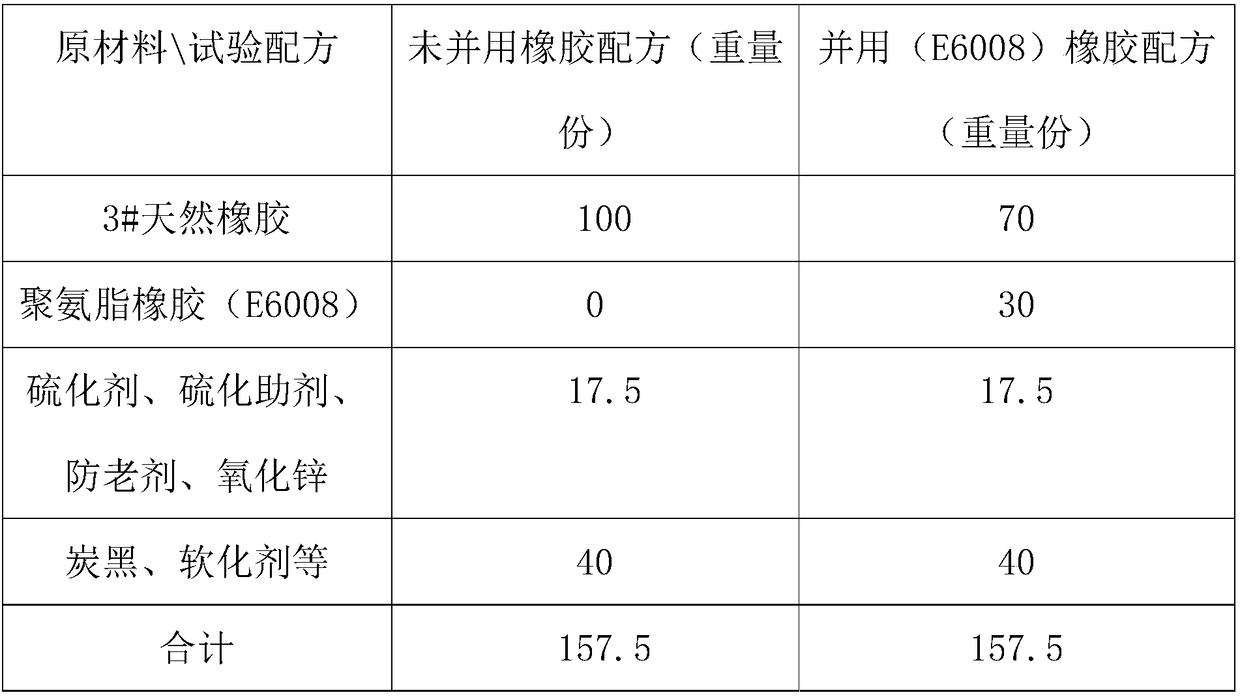

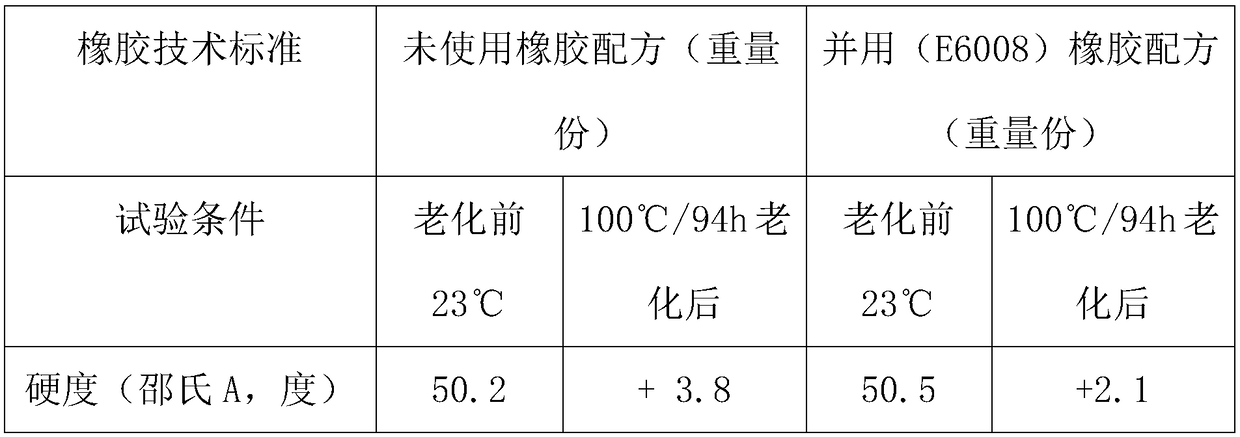

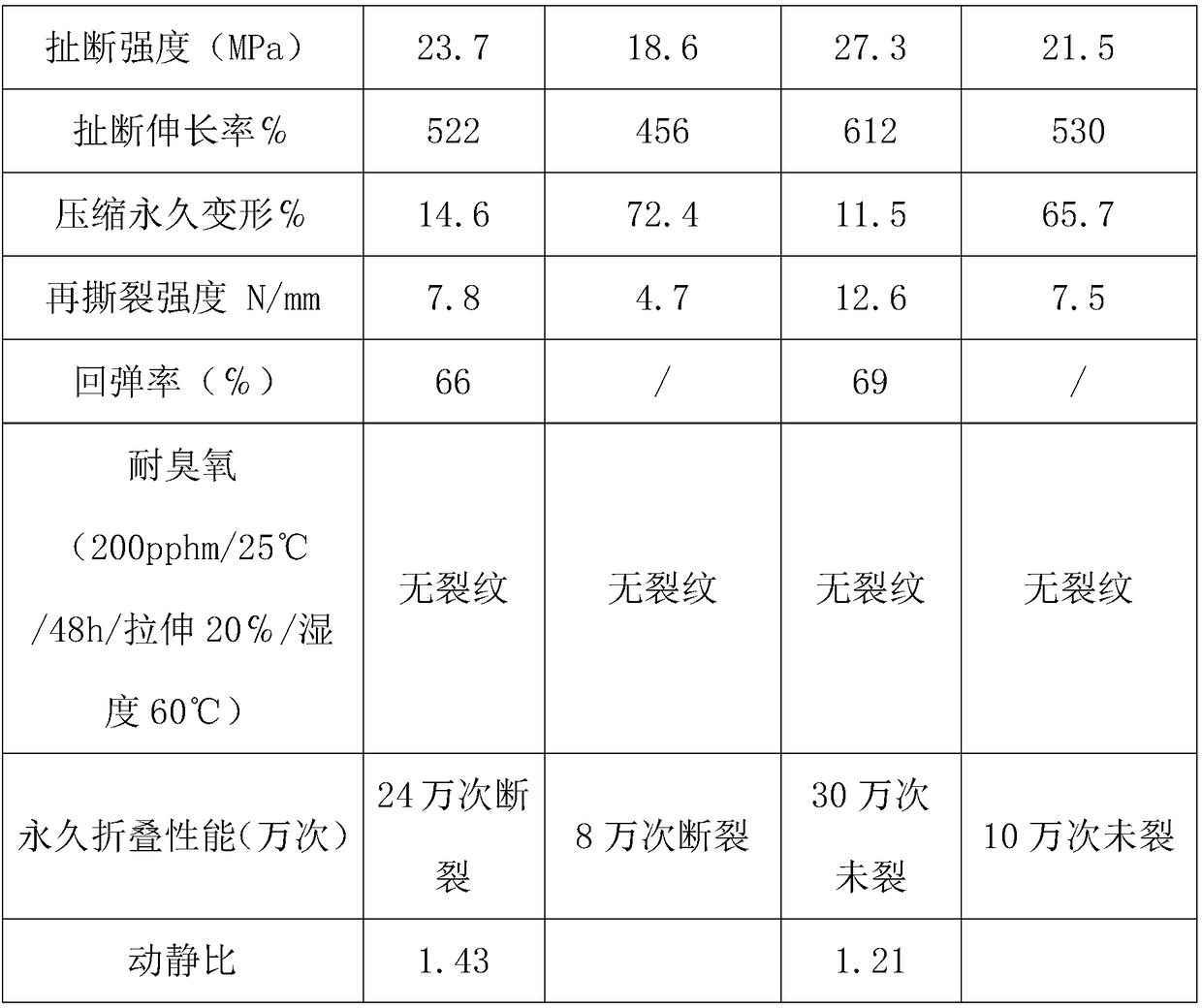

[0020] A rubber material, including 70 parts of natural rubber, 30 parts of polyurethane rubber, 0.5-1.5 parts of sulfur, 1-2.5 parts of vulcanization aid, 5-10 parts of anti-aging agent, 4-10 parts of zinc oxide, and 4 parts of white carbon black ~8 parts, carbon black 10~30 parts, softener 4~8 parts. Natural rubber and polyurethane rubber (E6008) are used together, polyester and polyether are mixed into the molecular chain of isoprene rubber as a flexible segment of rubber, and sulfur vulcanization system is used to improve the heat and oxygen resistance of natural rubber. (High temperature) aging, ozone aging resistance purpose.

[0021] As preferably, the vulcanization aid adopts 2-mercaptobenzothiazole, dibenzothiazole disulfide, N-cyclohexyl-2-benzothiazole sulfenamide, tetramethylthiuram disulfide, disulfide disulfide One or more of 1,5-pentylidene thiurams.

[0022] Described anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com