A method of preparing up-conversion and developing corrosion-resistant coating on the surface of magnesium alloy by using plasma spraying technology

A technology of plasma and magnesium alloy, which is applied in the field of preparation of development and corrosion-resistant coatings, can solve the problems of magnesium alloy biological activity, corrosion resistance, poor X-ray development, etc., to avoid radiation damage, solve corrosion problems, and improve biological activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

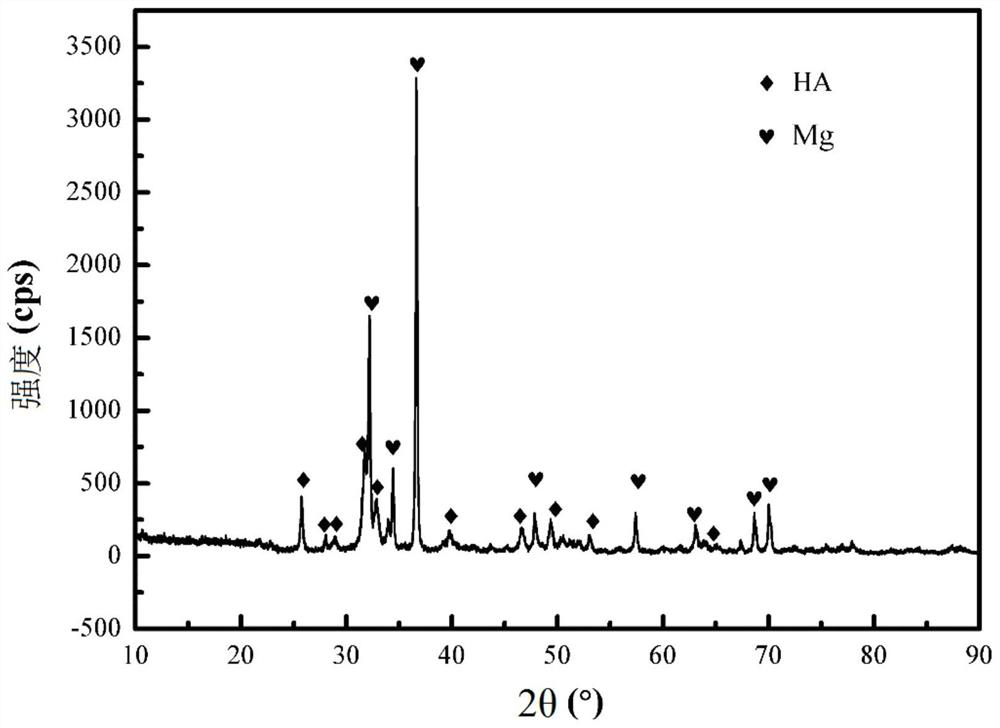

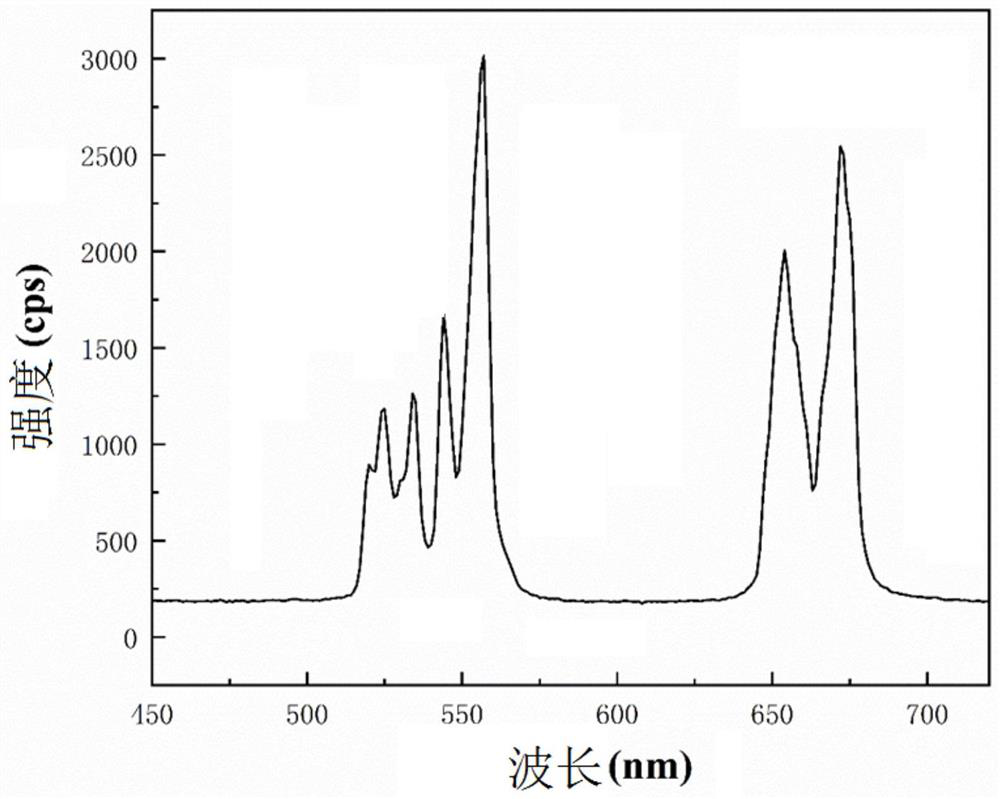

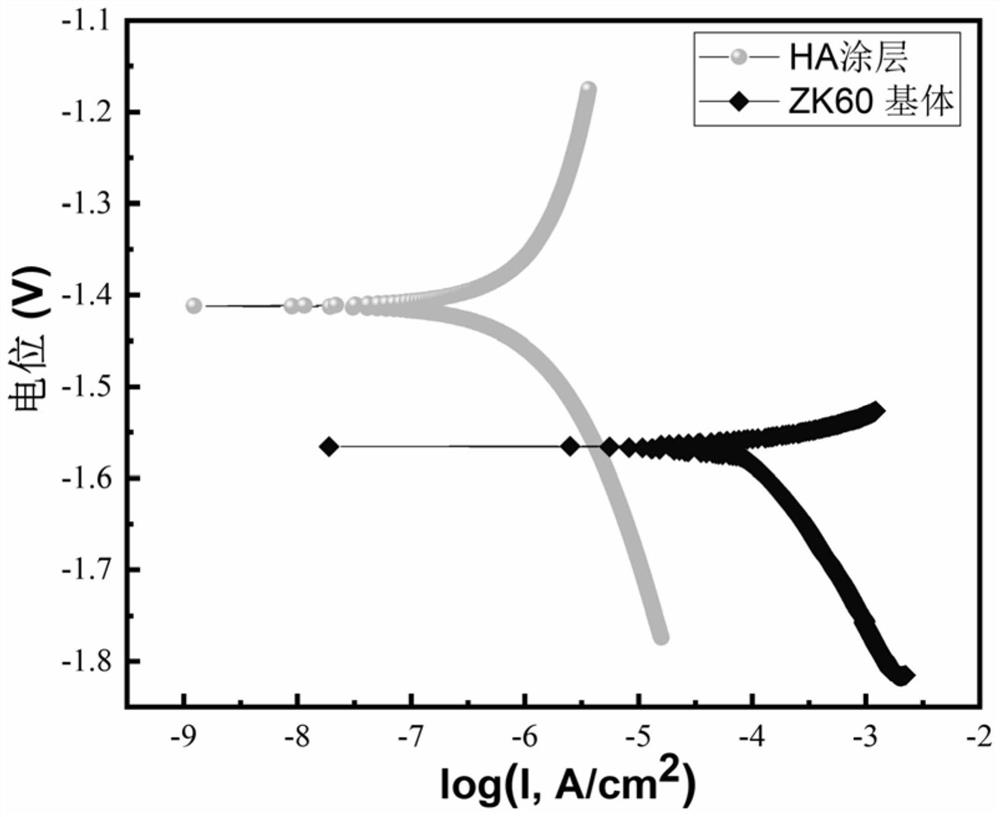

[0023] Specific Embodiment 1: This embodiment is a method for preparing an upconversion and development corrosion-resistant coating on the surface of a magnesium alloy using plasma spraying technology, which is completed in the following steps:

[0024] 1. Magnesium alloy pretreatment:

[0025] ①. Use 180#SiC sandpaper, 600#SiC sandpaper, 1000#SiC sandpaper and 2000#SiC sandpaper to polish the magnesium alloy in sequence to obtain a bright magnesium alloy;

[0026] ②. Use a dry sandblasting machine to perform sandblasting on the surface of the bright magnesium alloy to obtain a rough surface magnesium alloy;

[0027] 2. Ultrasonic degreasing: immerse the magnesium alloy with rough surface in acetone, and then ultrasonically treat it at an ultrasonic power of 800W-1200W for 10min-30min to obtain the magnesium alloy after ultrasonic treatment; rinse the magnesium alloy after ultrasonic treatment with distilled water 3 to 5 times, and then use a hair dryer to dry to obtain a deg...

specific Embodiment approach 2

[0038] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the sand grains used in the sand blasting treatment described in step ② are 280# white corundum sand, the sand blasting pressure is 0.2MPa, and the sand blasting distance is 100cm~ 120cm, sandblasting time is 0.5min ~ 1min. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the ball-to-material ratio of the ball mill described in step three is (3~6):1, and the ball milling speed is 250r / min~400r / min min, the ball milling time is 300-420 min. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com