Crystal furnace control method and system

A control method and technology for a control system, applied in the field of crystal furnace control methods and systems, can solve problems such as low yield, high price, and dependence on operator experience, and achieve the effects of preventing oxidation and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

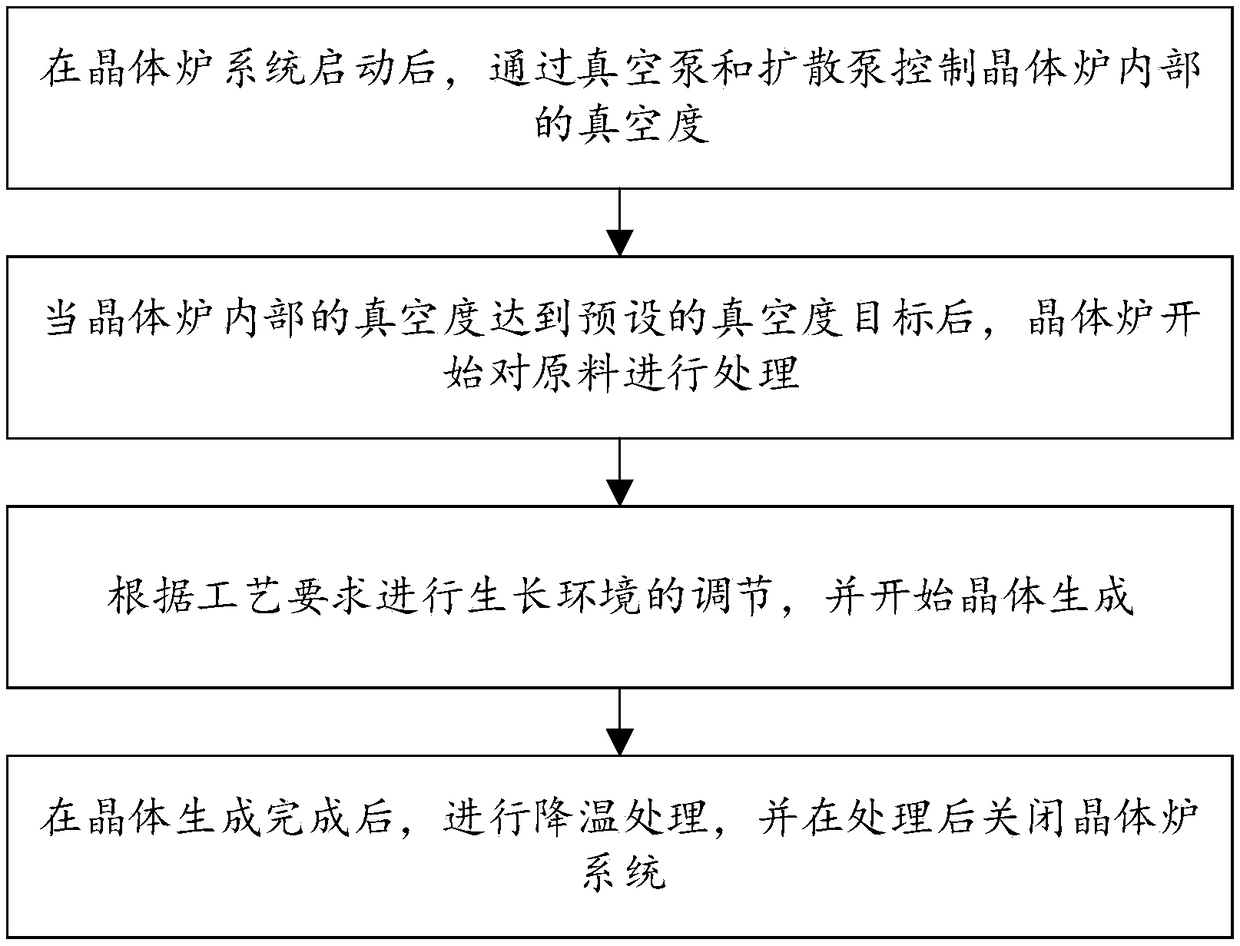

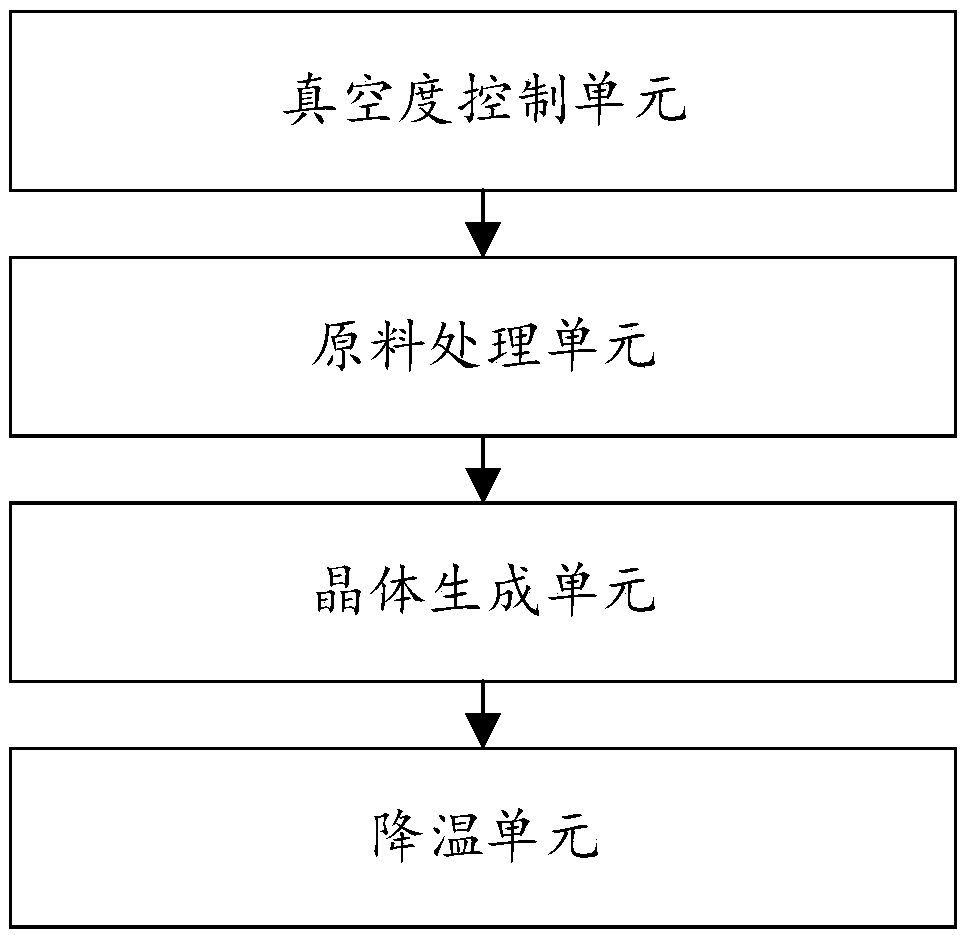

[0036] refer to figure 1 , the present invention a kind of crystal furnace control method, comprises the following steps:

[0037] After the crystal furnace system is started, the vacuum inside the crystal furnace is controlled by a vacuum pump and a diffusion pump;

[0038] When the vacuum degree inside the crystal furnace reaches the preset vacuum degree target, the crystal furnace starts to process the raw materials;

[0039] Adjust the growth environment according to the process requirements, and start crystal formation;

[0040] After the crystal formation is completed, the cooling process is performed, and the crystal furnace system is closed after the process.

[0041] In this embodiment, the present invention can effectively prevent oxidation of special materials in the furnace body by controlling the vacuum inside the furnace body. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com