Washing machine control method, system, computer equipment, readable storage medium and washing machine

A control method and control system technology, which is applied to the control device of washing machines, washing devices, textiles and papermaking, etc., can solve problems such as easy generation of noise, and achieve the effect of reducing violent shaking and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

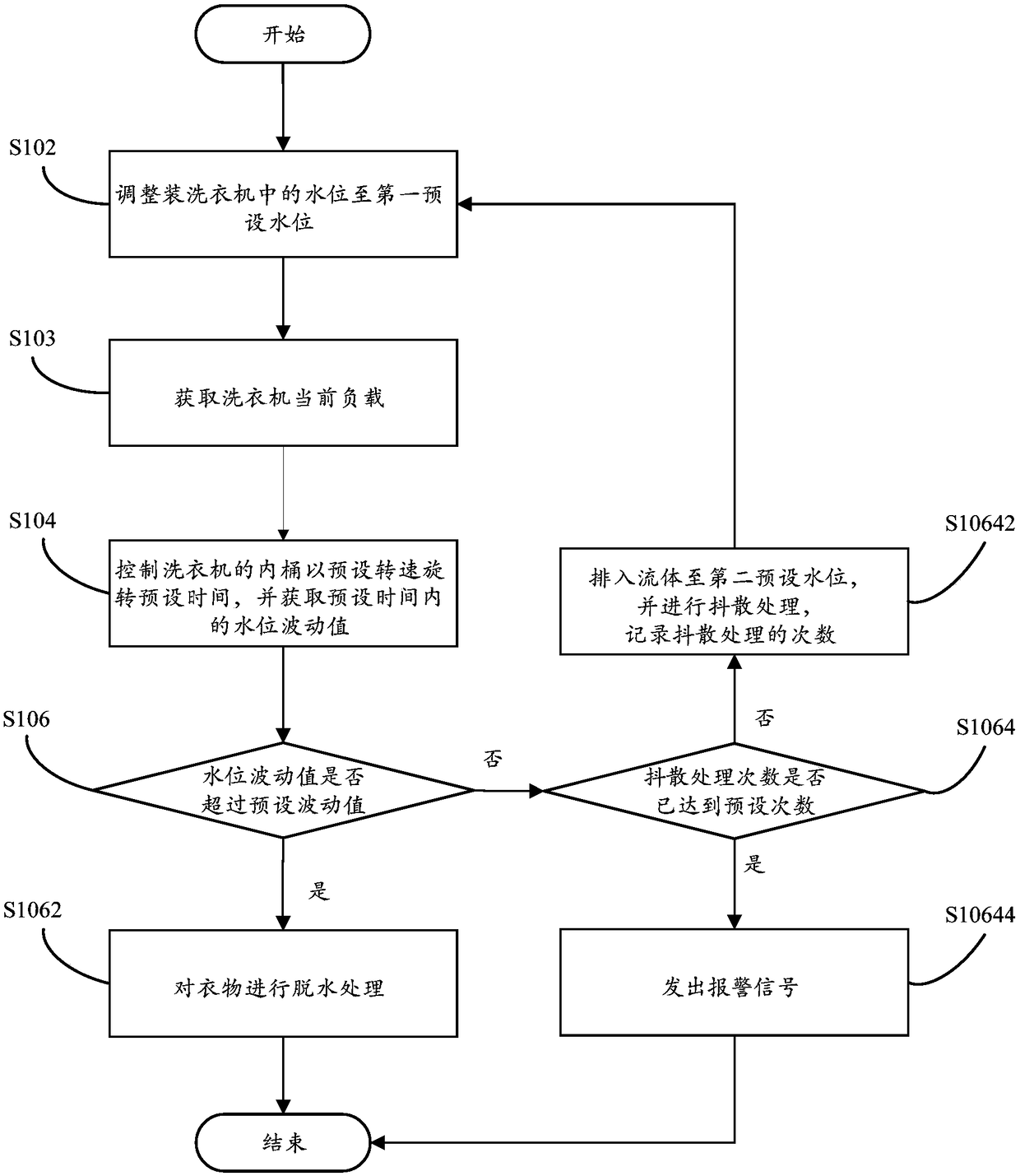

[0040] The first embodiment of the present invention provides a washing machine control method, such as figure 1 shown, including:

[0041] Step 102: Adjust the water level in the washing machine to the first preset water level;

[0042] After the clothes are washed, drain the water. The first preset water level that can be used for preliminary dehydration is preset in the washing machine. The water level sets a preliminary dehydration condition, so that the washing machine can determine whether the preliminary dehydration can be performed according to this condition.

[0043] Step 103: Obtain the current load of the washing machine;

[0044] After the drainage is completed, the load of the washing machine is mainly the clothes and the water contained in the clothes. During the high-speed rotation of dehydration, the clothes and the water in them will become the load of the washing machine, which will affect the balance of the washing machine's rotation and the highest water...

Embodiment 2

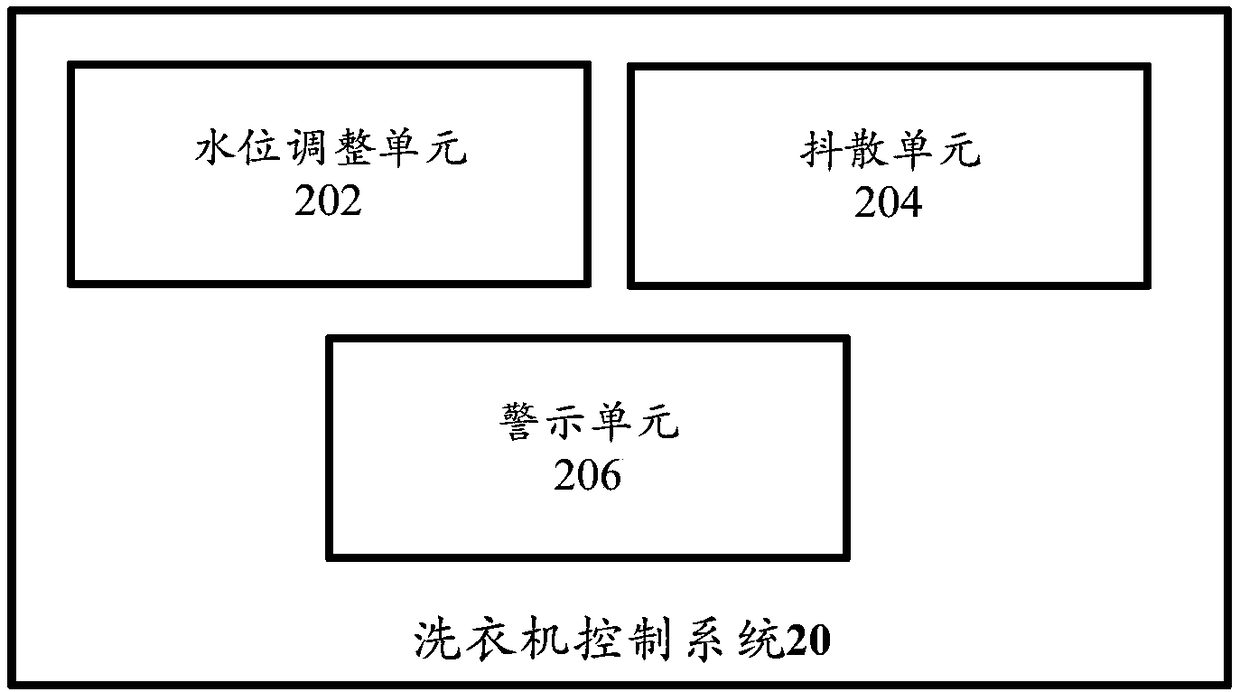

[0067] The second embodiment of the present invention provides a washing machine control system, such as figure 2 As shown, it includes a water level adjustment unit 202 and a shaking unit 204, and also includes a water level sensor arranged on the outer tub of the washing machine. When the clothes are dehydrated, the water in the washing machine is firstly discharged to the first preset water level through the water level adjustment unit 202, so as to prepare for preliminary dehydration and reduce the load of the washing machine during dehydration; The load rotates at the preset speed and time corresponding to the gear for preliminary dehydration. At the same time, the water level sensor detects the highest water level of the fluid within the preset time; compares the highest water level with the preset fluctuation value corresponding to the load of the washing machine, and at the highest water level When exceeding the preset fluctuation value corresponding to the weight of ...

Embodiment 3

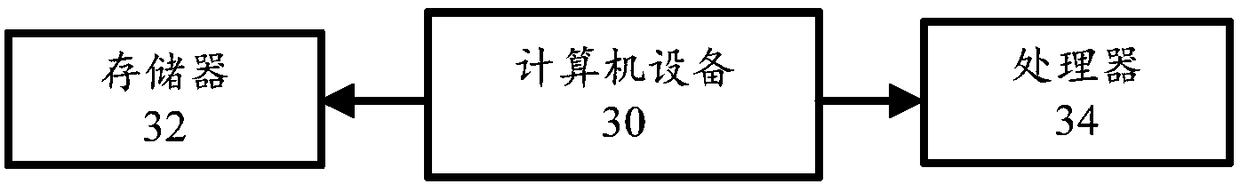

[0073] This embodiment provides a washing machine in combination with Embodiment 1 and Embodiment 2, such as image 3 and Figure 4 As shown, a computer device 30 is included to control the washing machine control system of Embodiment 2; a computer readable storage medium is included on the computer device 30, and a computer program corresponding to the washing machine control method of Embodiment 1 is stored, through Reading and running the computer program on the computer device 30 can execute the washing machine control method of Embodiment 1, so that the washing machine control system in Embodiment 2 can perform steps such as dehydration and shake-off processing, improve the automation of the washing machine, and reduce The shaking of the dehydration bucket caused by unevenness cancels the conventional bump switch, thereby reducing the noise and loss of the washing machine, prolonging the life of the washing machine and reducing labor intensity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com