Soft shaft speed change manipulator and automobile

A variable speed manipulator and flexible shaft technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as easy dust ingress, poor sealing, and large voids in ten-byte bearings. Achieve the effects of preventing dust from entering, small gaps, and small occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The core of the present invention is to provide a flexible shaft shifting manipulator, the rotating ball is in contact with the inner cavity of the floating bracket through a spherical surface to prevent dust from entering and reduce the volume of the manipulator.

[0037] In order to make those skilled in the art better understand the technical solution of the present invention, the flexible shaft transmission manipulator and the automobile of the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

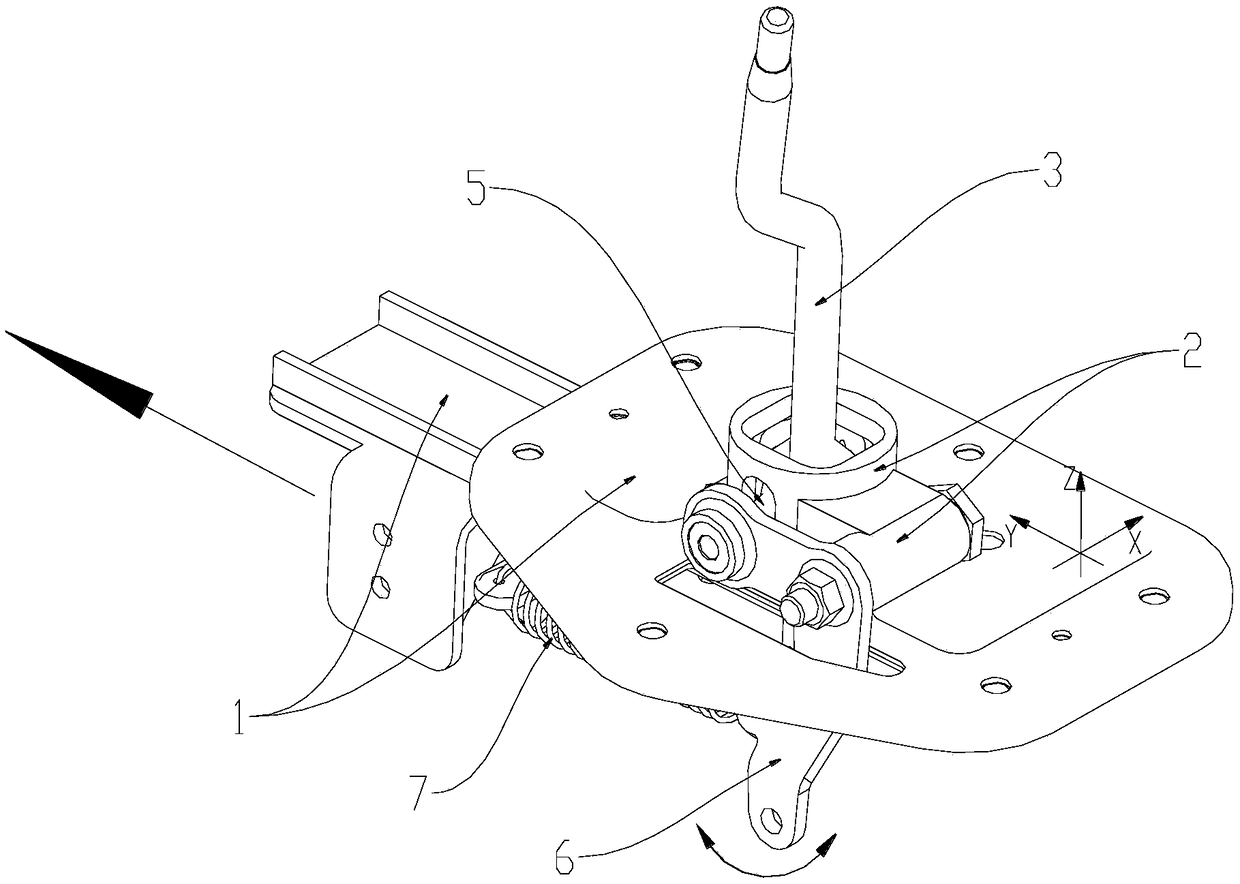

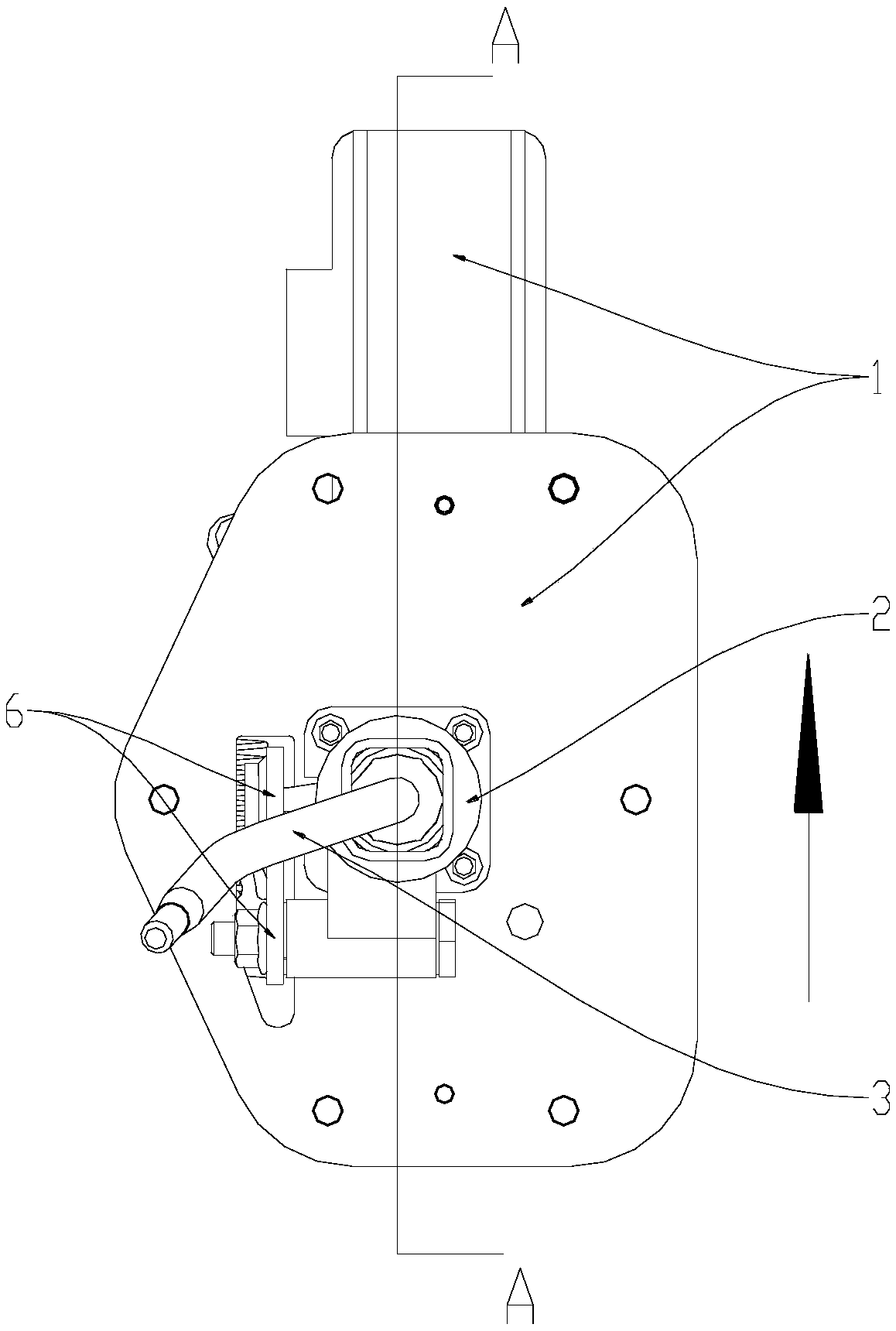

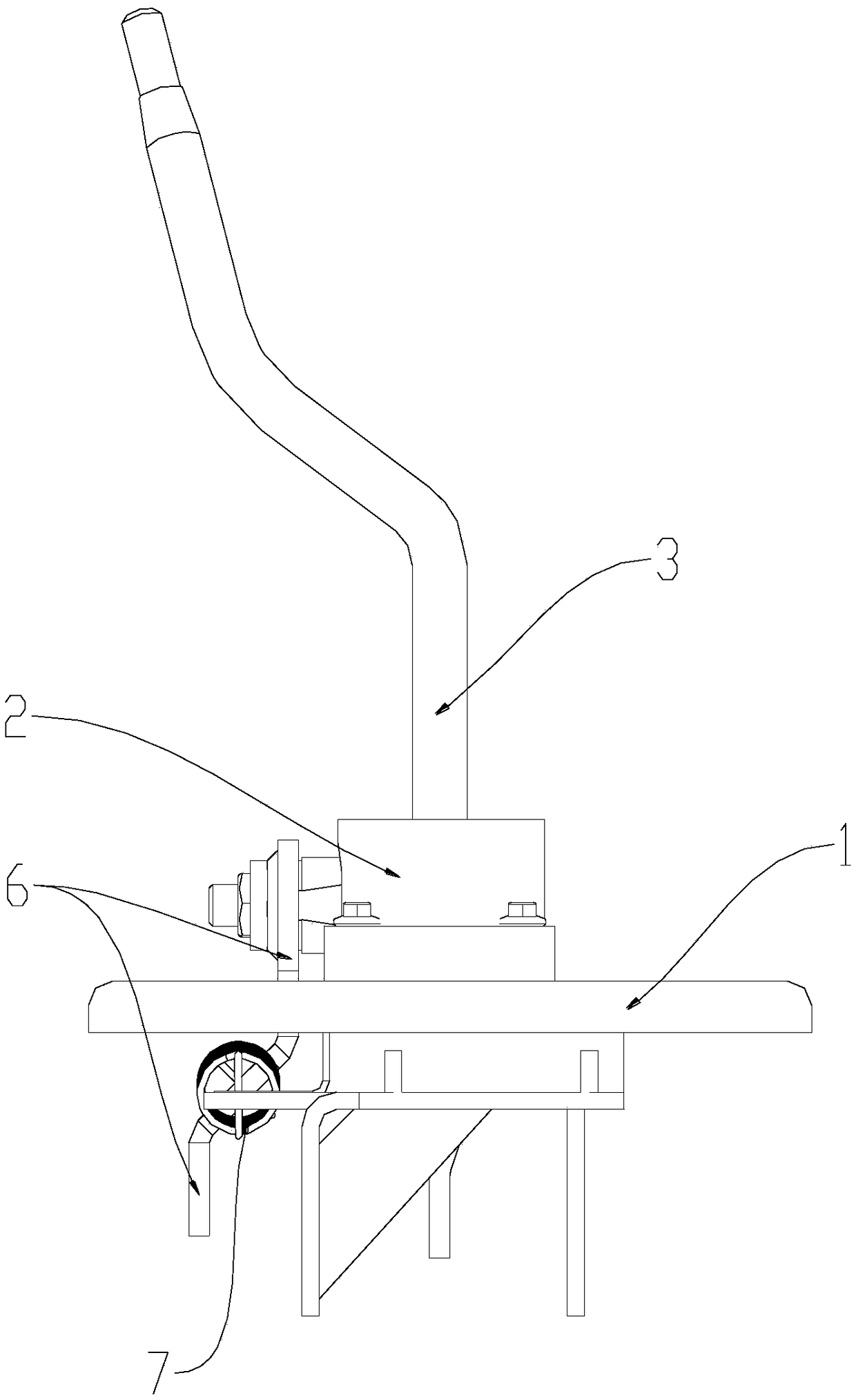

[0038] Such as figure 1 As shown, it is an axonometric structure diagram of a specific embodiment of the flexible shaft speed change manipulator provided by the present invention; Figure 2B A top view of a specific embodiment of the flexible shaft speed change manipulator provided by the present invention, Figure 2B and Figure 2C respectively Figure 2A top and bottom views of the fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com