Wear-free anti-erosion clutch valve

An anti-erosion, clutch valve technology, applied in the direction of the valve details, valve device, valve housing structure, etc., can solve the problems of cavitation, sealing pair wear, extended wrench, etc., to achieve anti-erosion phenomenon, reliable, no wear, reliable closed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

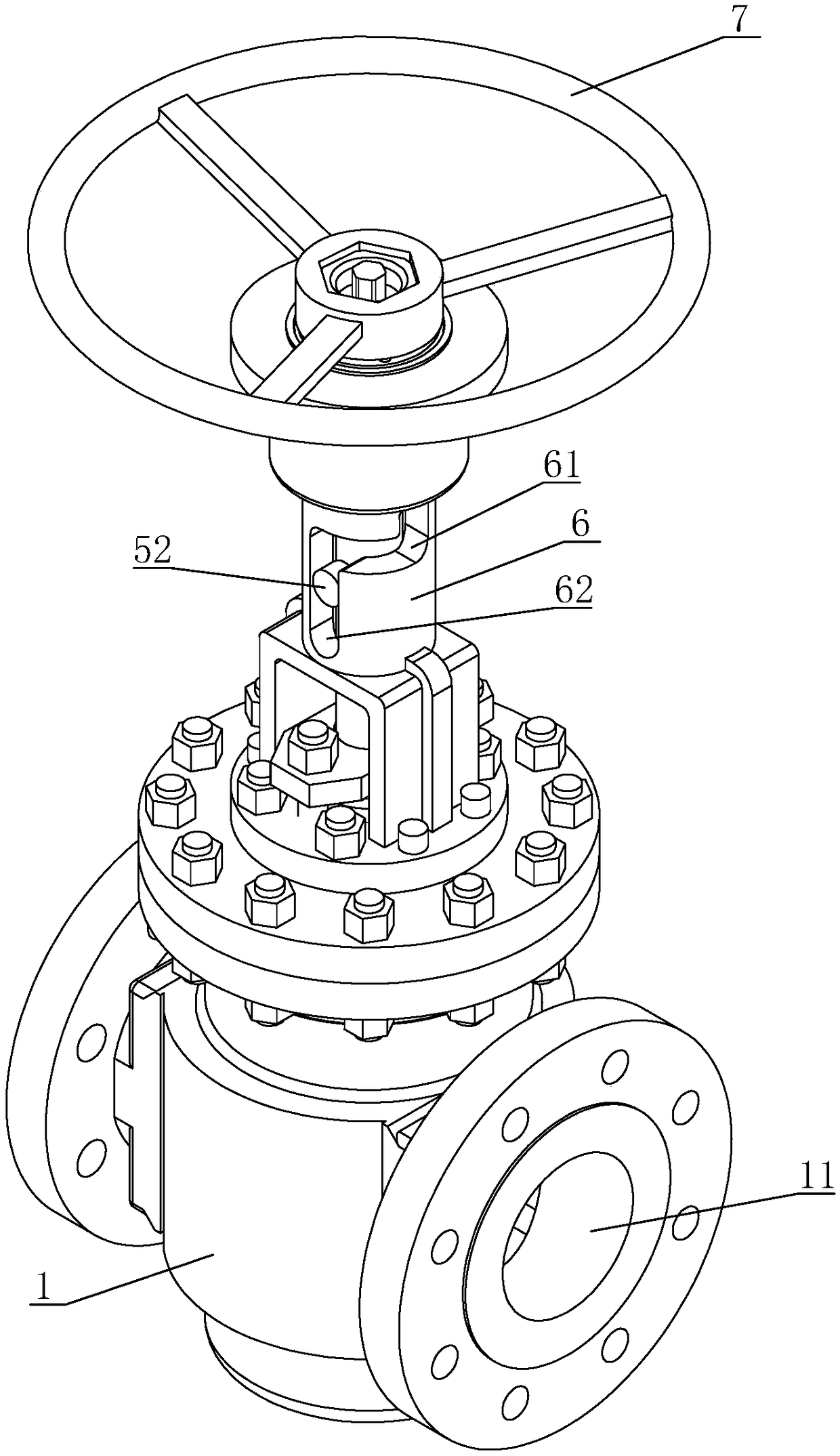

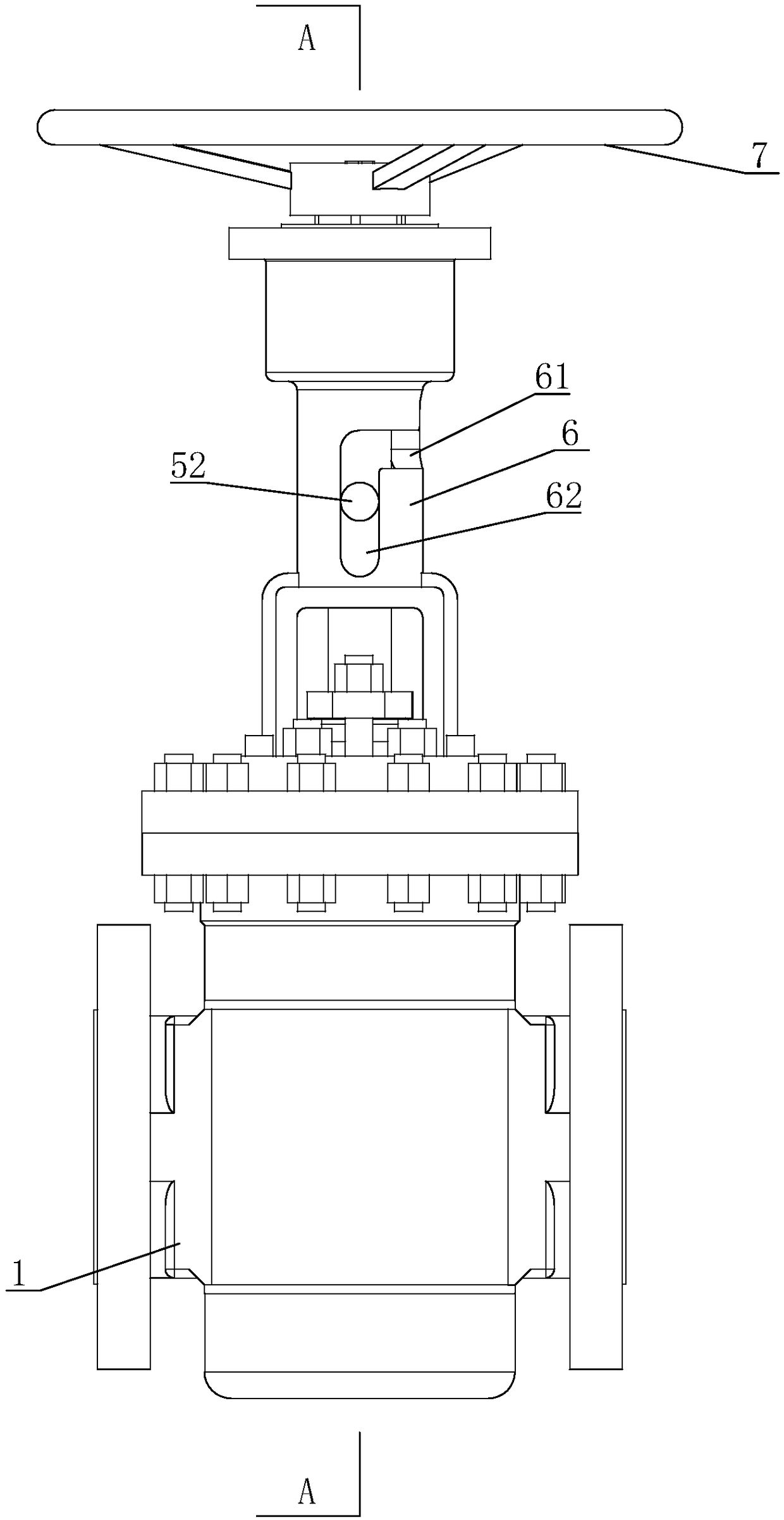

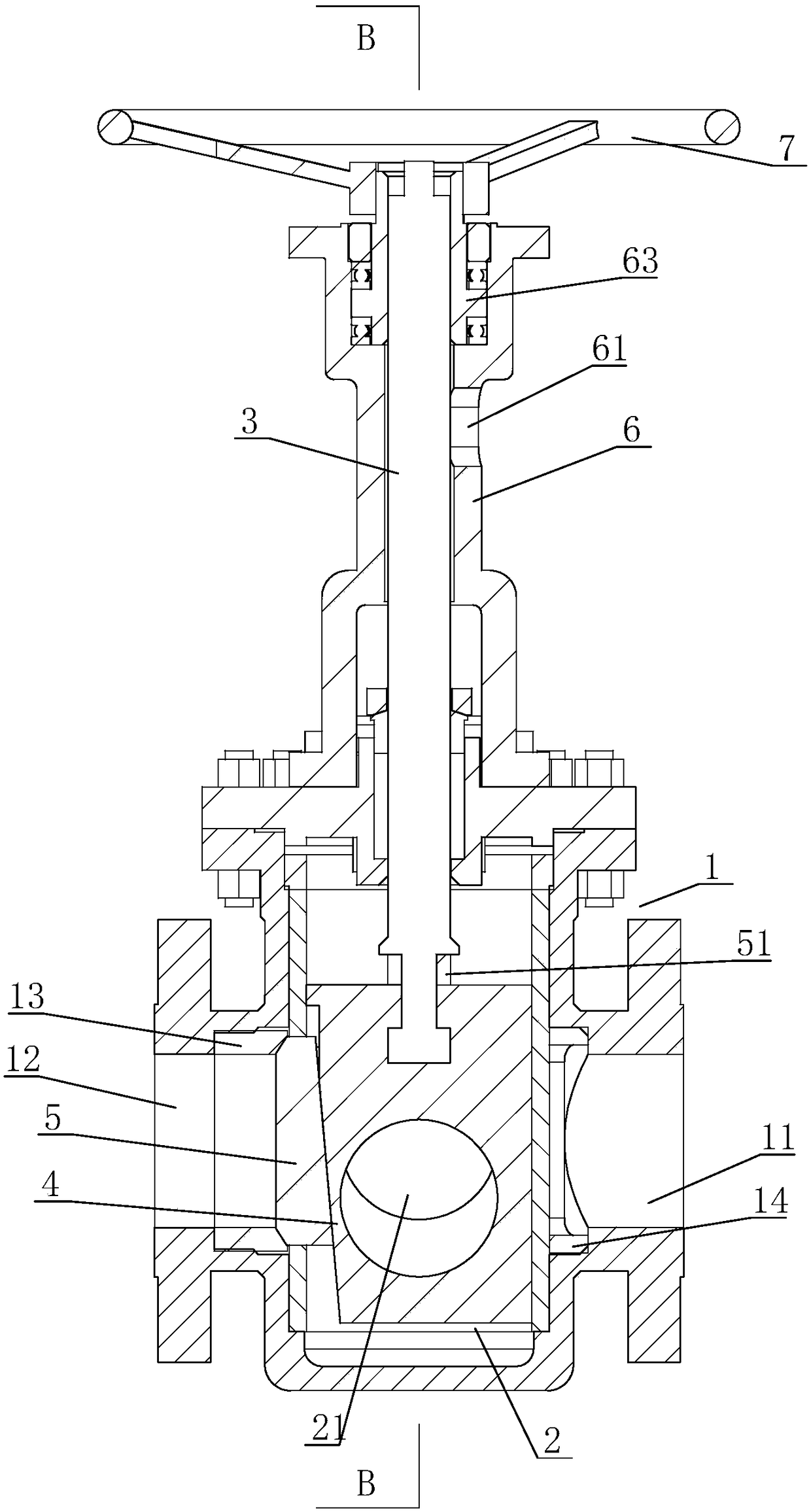

[0053] refer to Figure 1 to Figure 16 As shown, a wear-free and anti-erosion clutch valve of the present invention includes a valve body 1, a rotating valve core 2, and a valve stem 3. The valve body 1 is provided with an input port 11 and an output port 12, and the rotating valve core 2 is provided with a channel 21. One side of the channel 21 forms an input sealing surface 22 and the other side forms an output sealing surface 23. The valve stem 3 is connected to the rotating valve core 2 for rotation switching, wherein: a non-simultaneous opening / closing is formed between the input sealing surface 22 and the output sealing surface 23. The closed rotary opening and closing misalignment angle R2, when rotating, the input port 11 and the output port 12 are closed / opened sequentially.

[0054] The rotating spool 2 includes a lifting gate 4 and an opening and closing member 5 connected to one side of the lifting gate 4. The channel 21 is horizontally arranged in the lifting gate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com