Air microcirculation device for mold cutting worktable

A workbench and air technology, which is applied in home appliances, air conditioning systems, space heating and ventilation, etc., can solve the problem that the exhaust system cannot purify the air in the workshop in a timely and effective manner, the purification effect is not good, and the air pollutants cannot be fully and effectively purified And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention can be better understood from the following examples. However, those skilled in the art can easily understand that the content described in the embodiments is only for illustrating the present invention, and should not and will not limit the present invention described in the claims.

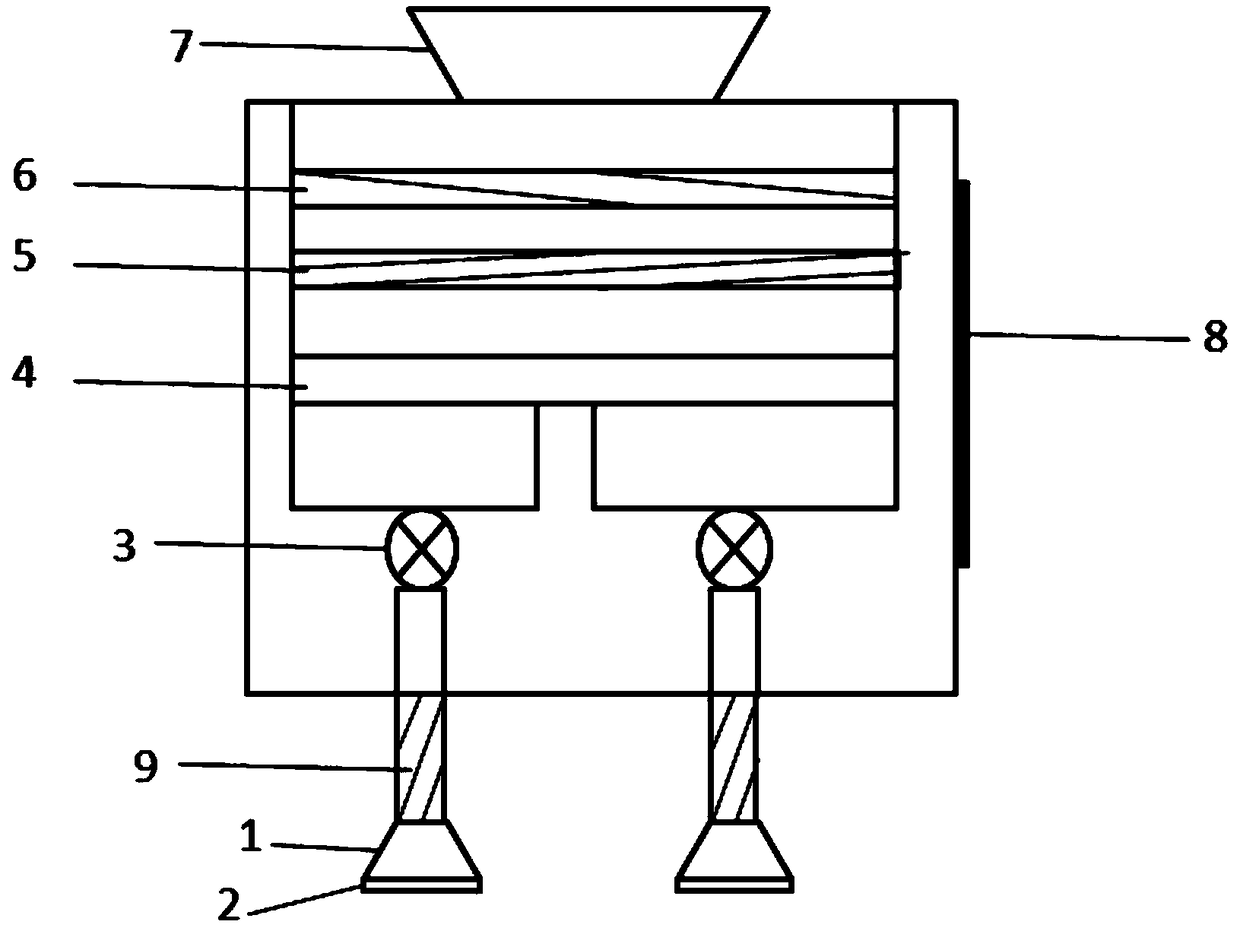

[0020] figure 1 , 1 is the air inlet, 2 is the humidification net, 3 is the air intake motor, 4 is the activated carbon filter, 5 is the first heavy metal adsorption module, 6 is the second heavy metal adsorption module, 7 is the air outlet, 8 is the magnetic sticker, 9 For the air intake duct.

[0021] An air microcirculation device for a mold cutting workbench, characterized in that it includes the following components: a power supply system, an air inlet system, a purification system, and an air outlet, and the air inlet system, the purification system, and the air outlet are respectively connected through pipelines, and the The purification system includes an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com