A calibration test device and test method for a liquid level gauge in a nuclear power plant ptr pool

The technology of a test device and test method is applied in the field of verification test device of PTR pool liquid level gauge of nuclear power plant, which can solve the problems of affecting the test progress, lack of test conditions, and many dust and sundries, so as to achieve strong promotion and application value and save test cost, the effect of huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to understand the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

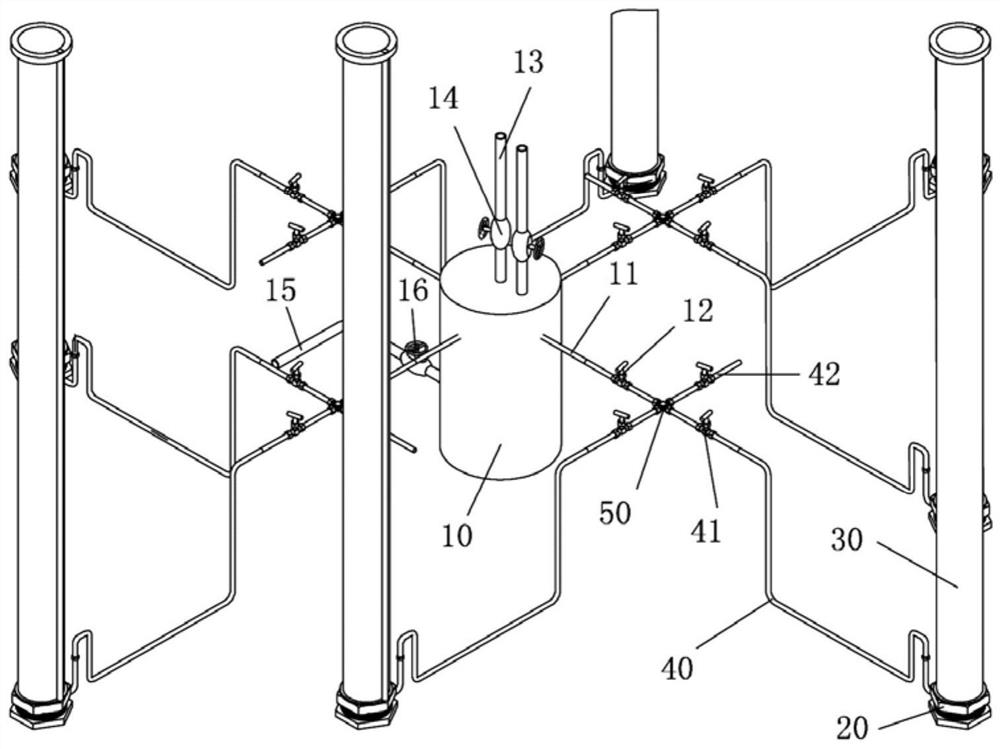

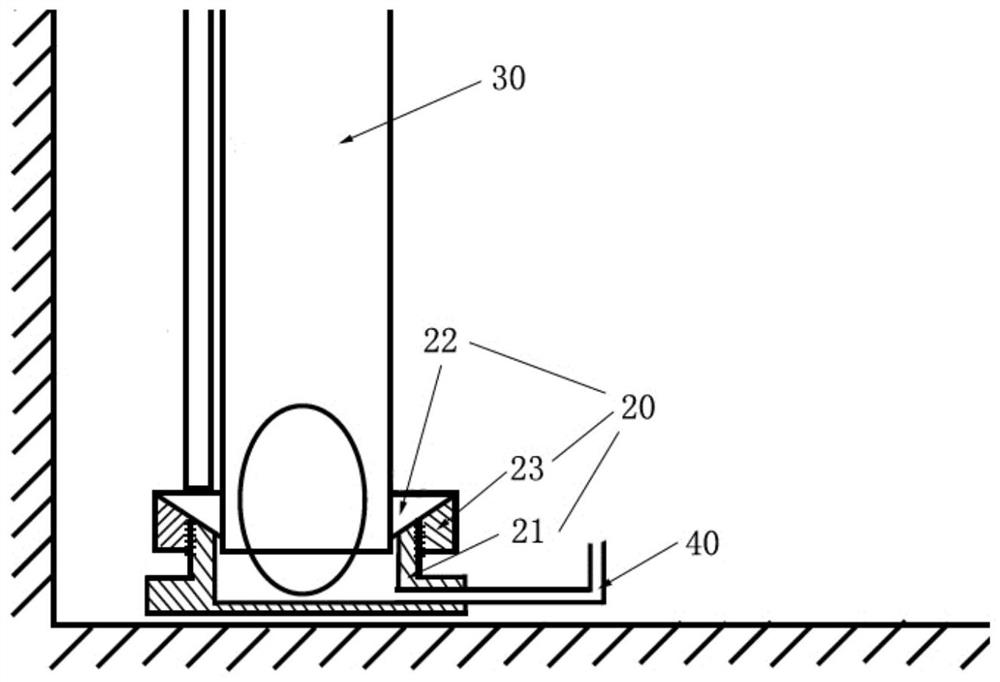

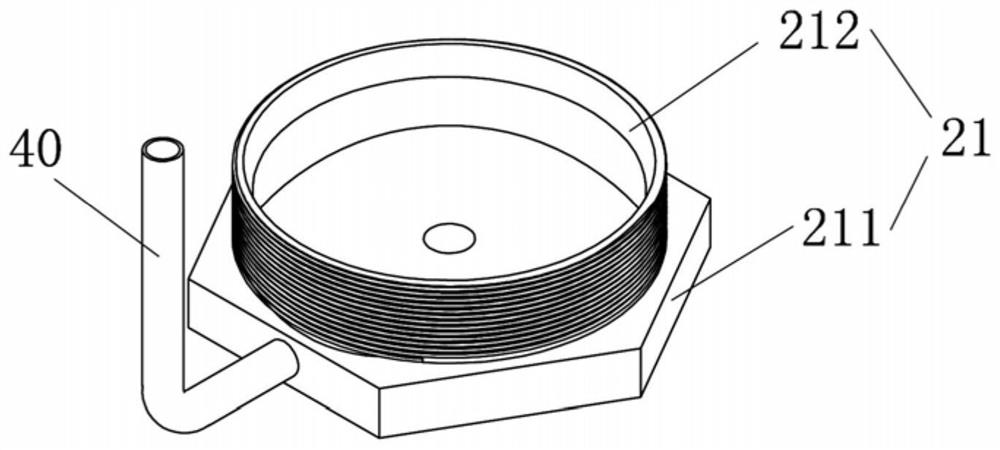

[0037] In order to solve the PTR pool level gauge calibration test in the prior art, it is necessary to perform repeated water filling comparisons on all level gauges. The test is risky, time-consuming, high-cost, and difficult to operate. In the initial stage of commissioning, it is difficult to have the test conditions on site. problem, and in order to meet the requirements for rapid comparison of the pool level gauge, save test time and schedule costs, the present invention aims to provide a nuclear power plant PTR pool level gauge verification test device and its test method, the core idea of which is : Based on the principle of the connecting device, a set of test equipment is designed to make all the liquid level gauges in the pool com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com