Optical dissolved oxygen sensor with automatic salinity compensation and manufacturing method thereof

A dissolved oxygen sensor and sensor probe technology, applied in the field of sensors, can solve the problems of short transmission distance and slow response speed, and achieve the effect of fast response time and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

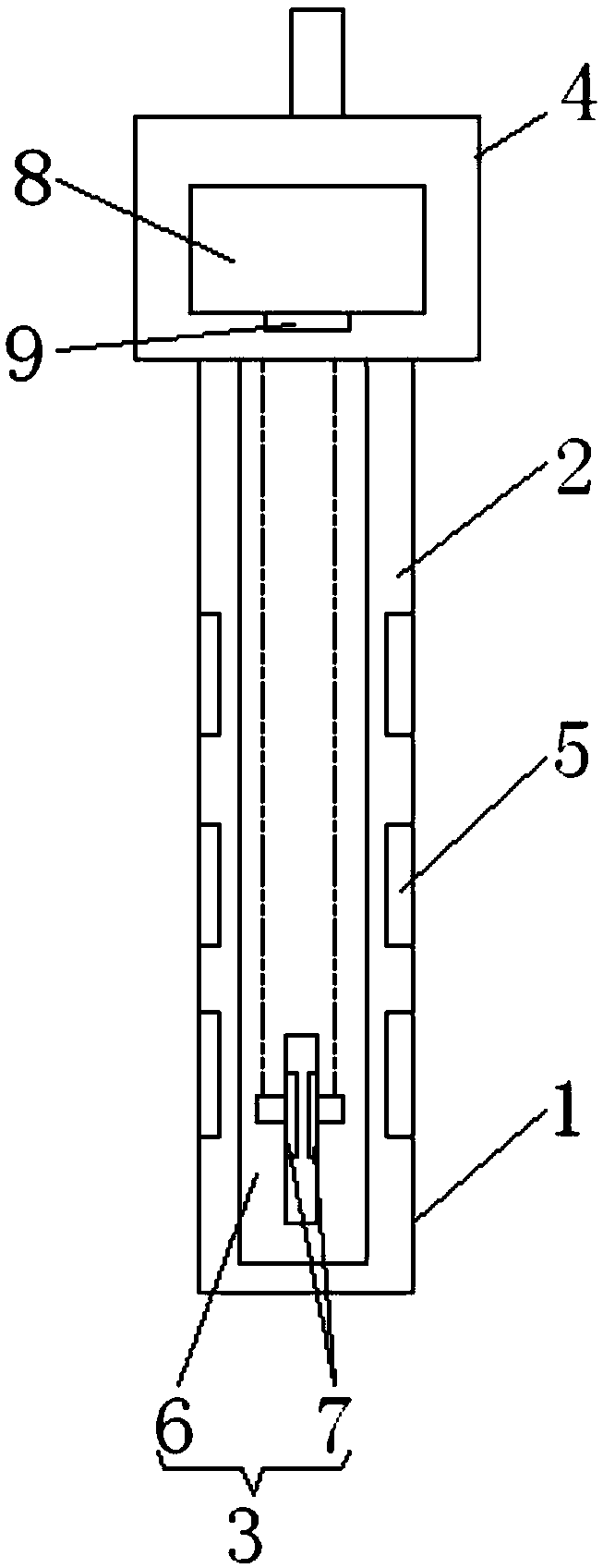

[0029] see image 3 As shown, an optical dissolved oxygen sensor with automatic salinity compensation includes a tubular sensor probe housing 1 with a cavity inside, an optical fiber or an optical fiber bundle 2 arranged in the sensor probe housing, an optical fiber or an optical fiber bundle The conductivity electrode 3 inside and the PCB module 4 located at the end of the sensor probe housing;

[0030] Two columns of photosensitive film assemblies are arranged at equal intervals along the circumference of the optical fiber or optical fiber bundle between the optical fiber or optical fiber bundle and the sensor probe housing, and each row of photosensitive film assemblies includes two photosensitive film units 5 arranged at equal intervals. A window corresponding to the photosensitive film unit is opened on the sensor probe;

[0031] The conductance electrode comprises a conductance electrode housing 6 and a conductance electrode sheet 7 arranged in the conductance electrode...

Embodiment 2

[0044] An optical dissolved oxygen sensor with automatic salinity compensation, comprising a tubular sensor probe housing 1 with a cavity inside, an optical fiber or an optical fiber bundle 2 arranged in the sensor probe housing, a conductance sensor arranged in the optical fiber or the optical fiber bundle The electrode 3 and the PCB board module 4 arranged at the end of the sensor probe housing;

[0045] Between the optical fiber or optical fiber bundle and the sensor probe housing, three rows of photosensitive film assemblies are arranged at equal intervals along the circumference of the optical fiber or optical fiber bundle, and each row of photosensitive film assemblies includes three photosensitive film units 5 arranged at equal intervals. A window corresponding to the photosensitive film unit is opened on the sensor probe;

[0046]The conductance electrode comprises a conductance electrode housing 6 and a conductance electrode sheet 7 arranged in the conductance electro...

Embodiment 3

[0053] An optical dissolved oxygen sensor with automatic salinity compensation, comprising a tubular sensor probe housing 1 with a cavity inside, an optical fiber or an optical fiber bundle 2 arranged in the sensor probe housing, a conductance sensor arranged in the optical fiber or the optical fiber bundle The electrode 3 and the PCB board module 4 arranged at the end of the sensor probe housing;

[0054] Four rows of photosensitive film assemblies are arranged between the optical fiber or optical fiber bundle and the sensor probe housing at unequal intervals along the circumferential direction of the optical fiber or optical fiber bundle, and each row of photosensitive film assemblies includes four photosensitive film units 5 arranged at unequal intervals, A window corresponding to the photosensitive film is opened on the sensor probe;

[0055] The conductance electrode comprises a conductance electrode housing 6 and a conductance electrode sheet 7 arranged in the conductanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com