Rare-earth-doped ZnO nanocrystal temperature and humidity sensing material and preparation method thereof

A nanocrystalline material and humidity sensing technology, which is applied in the direction of luminescent materials, chemical instruments and methods, measuring devices, etc., can solve the problems of temperature sensitivity, humidity response range, and unsatisfactory response speed performance, and achieve high sensitivity and easy operation , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 1.0975mg zinc acetate (Zn(OAc) 2 2H 2 O), 0.0443mg erbium nitrate (Er(NO 3 ) 3 ·5H 2 O) and 0.4490mg ytterbium nitrate (Yb(NO 3 ) 3 ·5H 2 (0), the above-mentioned weighed material is dissolved in 50mL of diethylene glycol (DEG) and stirred until completely dissolved, then loaded into a microwave reactor with a reflux device, and heated at a rate of 100° C. / min under normal pressure to 150°C and hold at this temperature for 5 minutes. After the heat preservation is completed, cool to room temperature, centrifuge the suspension prepared above, remove the supernatant, and then put it into an absolute ethanol solution for 10 minutes according to the concentration ratio of 0.5g / L; The ethanol suspension was further centrifuged, the supernatant was removed, and dried in a drying oven at 100° C. for 2 hours to obtain a rare earth-doped ZnO nanocrystal material.

Embodiment 2

[0029] Weigh 1.4875mg zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O), 0.0416mg erbium acetate (Er(OAc) 3 4H 2 O) and 0.4222mg ytterbium acetate (Yb(OAc) 3 4H 2 (0), the above-mentioned weighed material is dissolved in 50mL of diethylene glycol (DEG) and stirred until completely dissolved, then loaded into a microwave reactor with a reflux device, and heated at a rate of 80°C / min under normal pressure to 180°C and hold at this temperature for 5 minutes. After the heat preservation is completed, cool to room temperature, centrifuge the suspension prepared above, remove the supernatant, and then put it into an absolute ethanol solution for 10 minutes according to the concentration ratio of 0.5g / L; The ethanol suspension was further centrifuged, the supernatant was removed, and dried in a drying oven at 100° C. for 2 hours to obtain a rare earth-doped ZnO nanocrystal material.

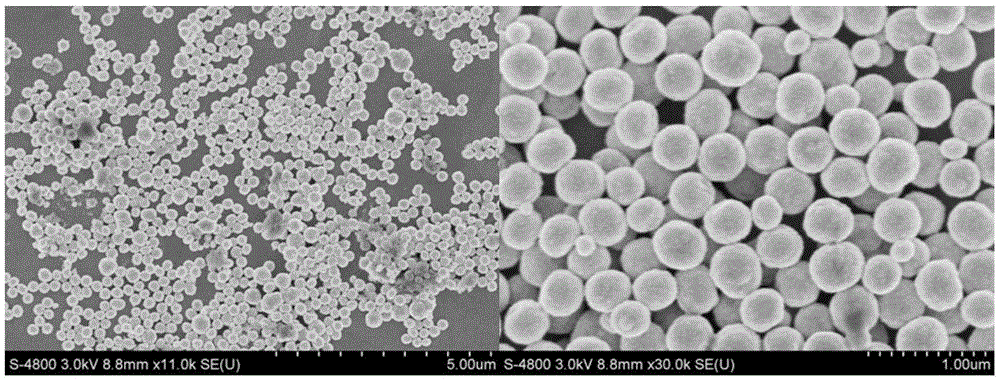

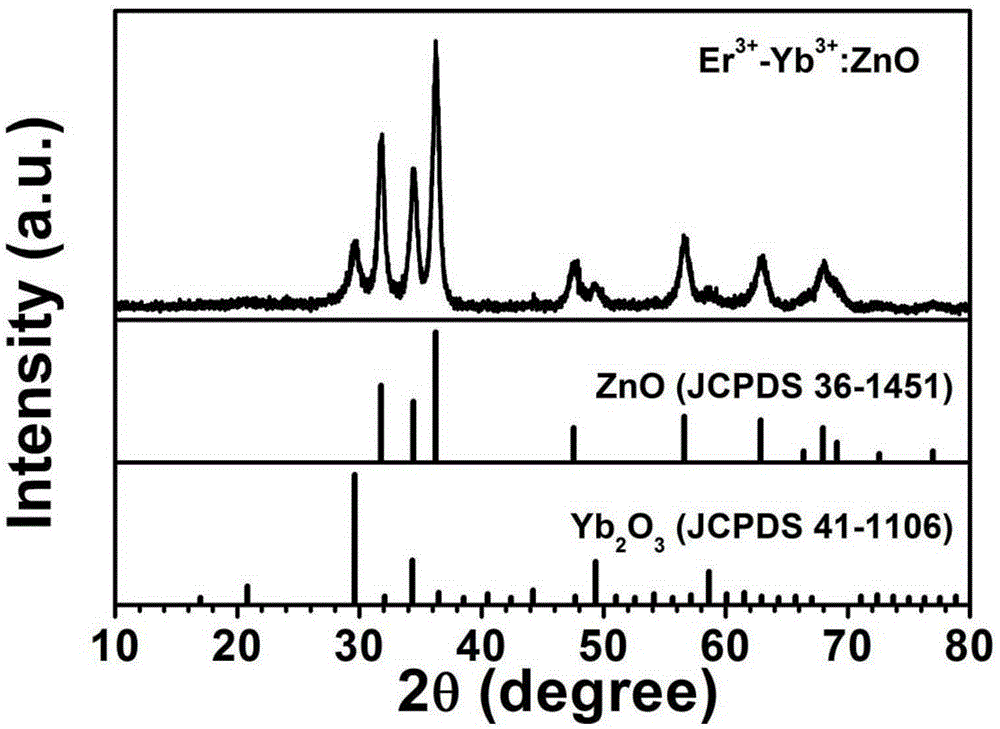

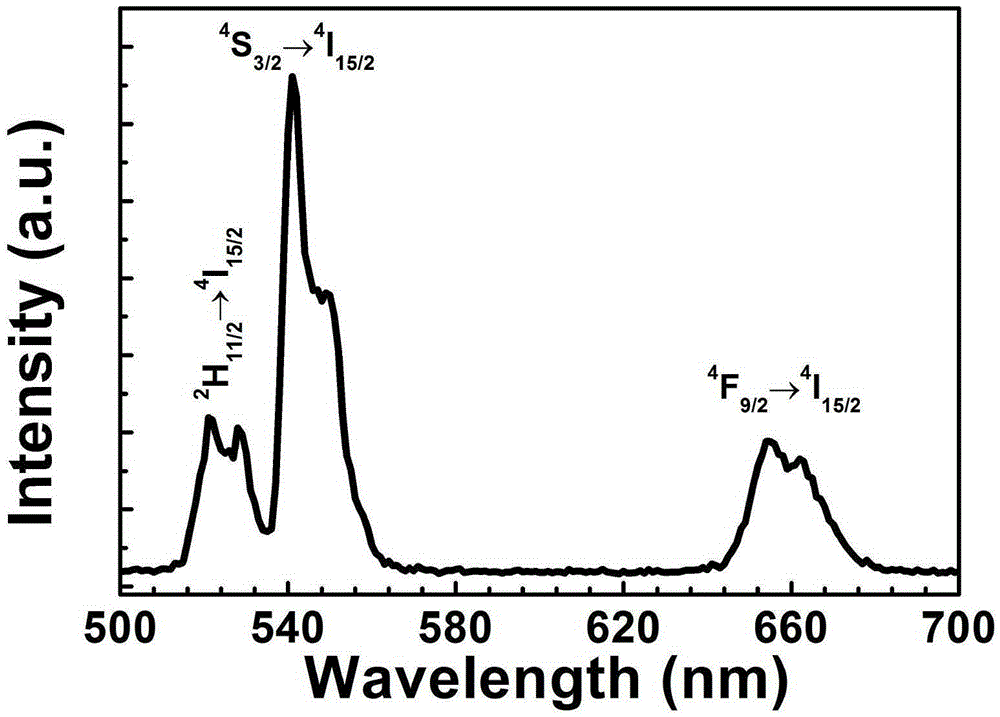

[0030] From figure 1 From the scanning electron micrographs of the temperature and humidity sensing materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com