Double-stirring-mode constant-temperature reaction device suitable for hydrolysis and saccharification of straw fibers

A straw fiber and reaction device technology, applied in the field of double-stirring mode constant temperature reaction device, can solve the problems of difficult hydrolysis, long straw fiber, lack of precise temperature, pH and rotational speed control system, etc., to reduce particle size and promote The effect of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

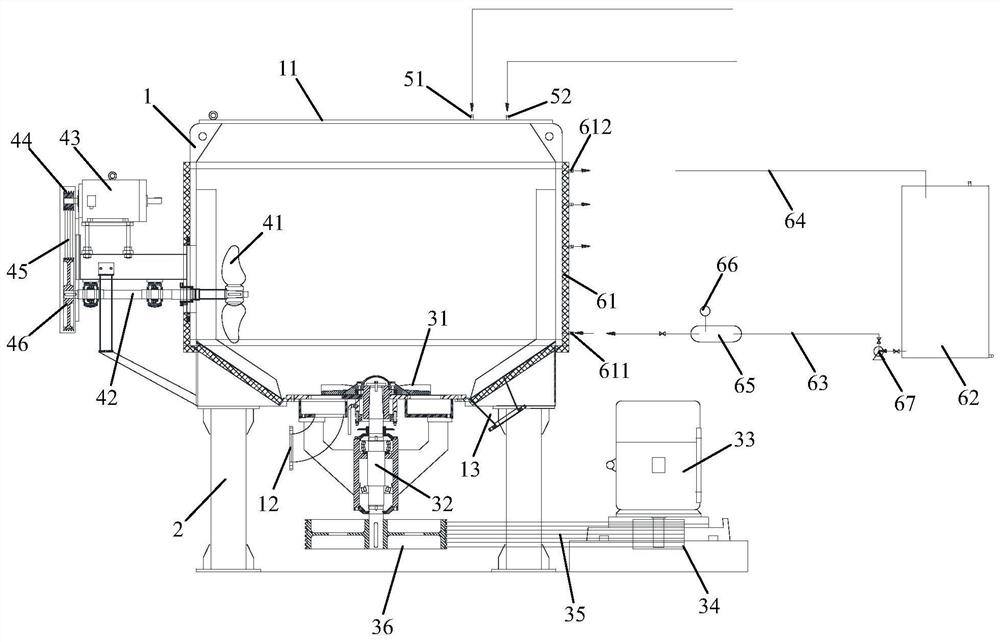

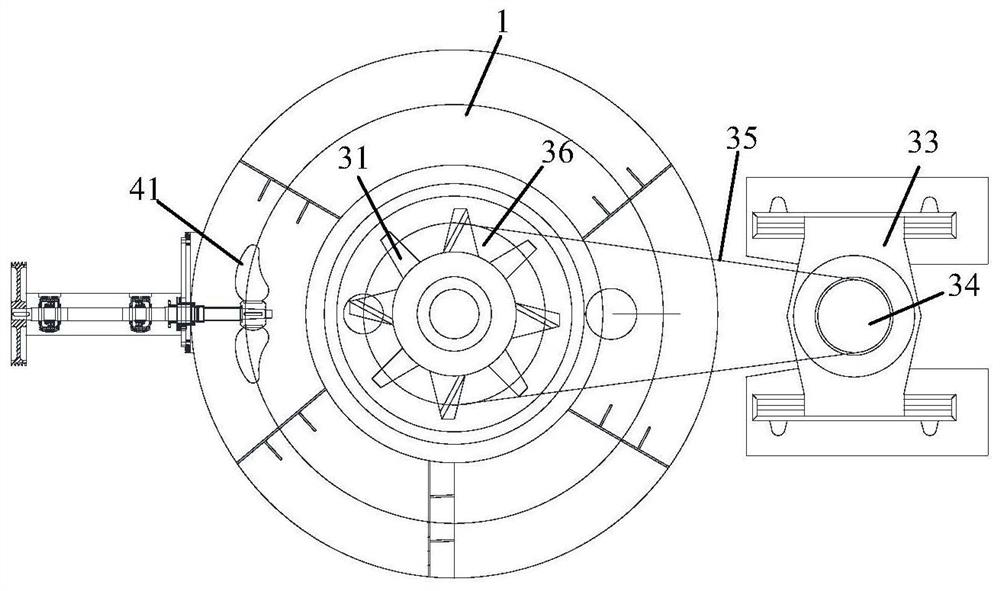

[0030] The internal volume of the device is 10m 3 , according to the solid content of 10% by mass fraction, add water and treated wheat straw fibers at one time, open the first stirring assembly to break up the straw fibers, then close the first stirring assembly, open the second stirring assembly, keep running, and make the straw The fibers are evenly distributed in the hydrolysis system.

[0031] The temperature of the hydrolysis system inside the device is controlled at 50°C by the temperature control component, and the pH value of the hydrolysis system is adjusted to 5.0 through the acid inlet and the alkali inlet.

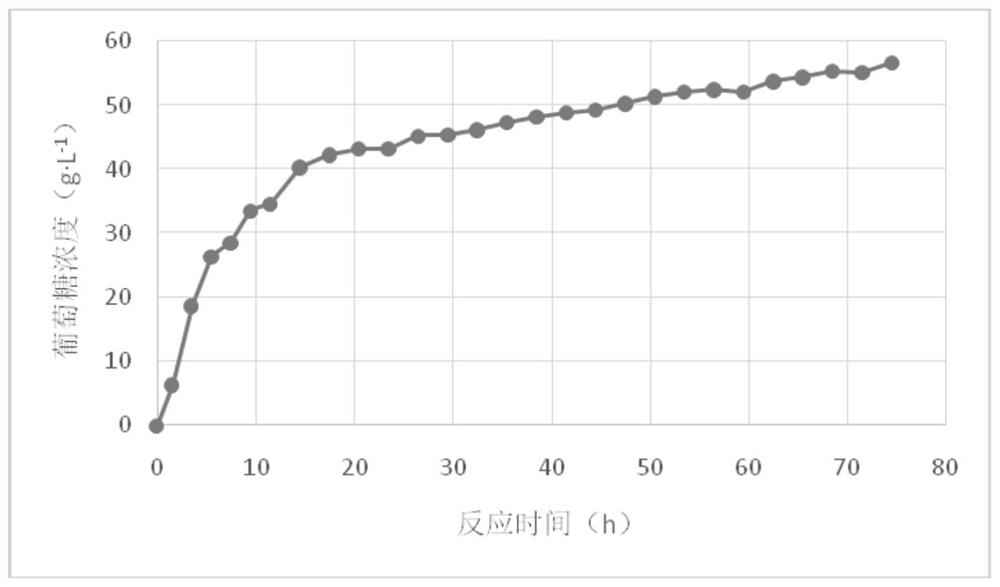

[0032] Enzyme solution and straw fiber absolute dry weight are added at a ratio of 50ml: 1kg, and the glucose concentration results are as follows: image 3 As shown, the final sugar concentration can reach 56.53g / L. By using the device to hydrolyze wheat fiber, sugar can be produced continuously within 72 hours, and the hydrolysis effect is relatively stabl...

Embodiment 2

[0034] The device is used to hydrolyze the pretreated corn stalk fiber in batch feeding mode. The specific operation is as follows: the absolute dry weight of the enzyme solution and the straw fiber is added at a ratio of 50ml: 1kg. The enzyme solution is added at one time, and the pretreated corn straw fiber is added in batches according to the total solid content of 15% by mass fraction. Add materials at 1, 2, 2.5, 3.5, 5.5, 7.5 hours, open the first stirring component after each feed, and close after the fibers are broken. All the other operations are as example one, and the insoluble content in the glucose concentration and the reaction system is as follows: Figure 4 As shown, the final sugar concentration can reach 81g / L, and a stable sugar increase can be maintained within 72h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com