Measurement device and method for sealing performance of firefighting foam

A technology for sealing performance and measuring device, which is applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as difficult implementation, lack of fire-fighting foam sealing, and inability to quantitatively analyze the sealing performance of fuel vapor by foam, and achieve the effect of ingenious structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

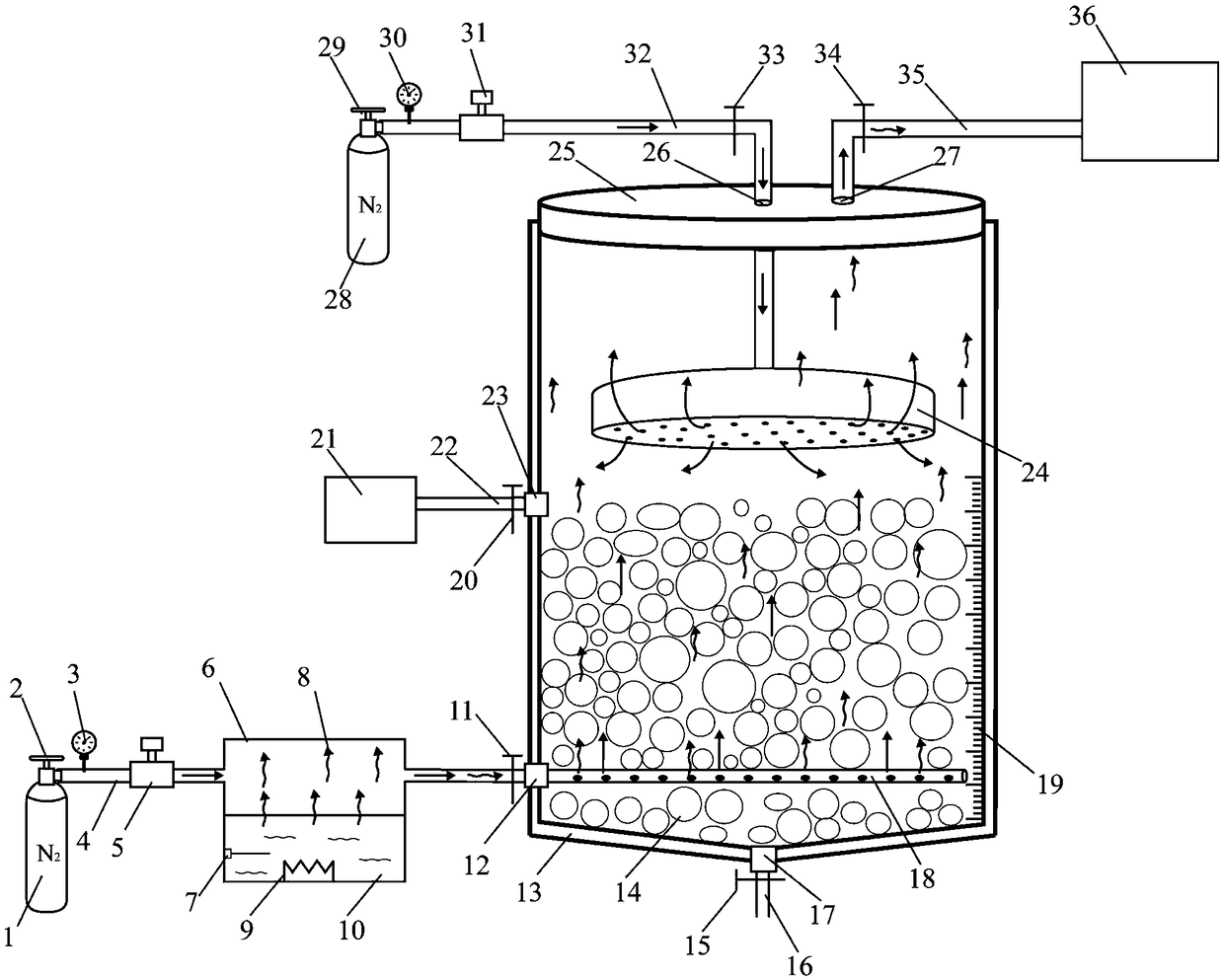

[0034]1. Close the valve I 11, the valve II 15, the valve III 20, the valve IV 33, and the valve V 34, and turn on the heater 9 to keep the temperature of the fuel A in the fuel tank 6 stable.

[0035] 2. Open the valve III 20 of the foam inlet pipe 22, open the foam generator 21 and slowly inject 400ml of fire-fighting foam A into the plexiglass container 13.

[0036] 3. Open the valve IV 33 and valve V 34 while injecting the fire-fighting foam A, open the gas cylinder valve II 29 of the nitrogen gas cylinder II 28, adjust the flow controller II 31 to set the nitrogen flow rate to 200mL / min, and make the nitrogen gas flow through The air inlet pipe 32 slowly sweeps the foam surface from the lower part of the porous glass plate 24, and at the same time, the gas chromatograph 36 is turned on, and the gas flowing out of the gas port 27 is continuously detected by the gas chromatograph 36.

[0037] 4. Open the valve I11, open the gas cylinder valve II2 of the nitrogen gas cylinde...

Embodiment 2

[0042] 1. Close the valve I 11, the valve II 15, the valve III 20, the valve IV 33, and the valve V 34, and turn on the heater 9 to keep the temperature of the fuel A in the fuel tank 6 stable.

[0043] 2. Open the valve III 20 of the foam inlet pipe 22, open the foam generator 21, and slowly inject 400 ml of fire-fighting foam A into the plexiglass container 13.

[0044] 3. Open the valve IV 33 and valve V 34 while injecting the fire-fighting foam A, open the gas cylinder valve II 29 of the nitrogen gas cylinder II 28, adjust the flow controller II 31 to set the nitrogen flow rate to 200mL / min, and make the nitrogen gas flow through The air inlet pipe 32 slowly sweeps the foam surface from the lower part of the porous glass plate 24, and at the same time, the gas chromatograph 36 is turned on, and the gas flowing out of the gas port 27 is continuously detected by the gas chromatograph 36.

[0045] 4. Open the valve I 11, open the gas cylinder valve II 2 of the nitrogen gas cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com