Method for determining optimal horizontal stiffness and damping value of dynamic vibration absorption type high pier-beam connection

A technology of dynamic vibration absorption and determination method, which is applied in the field of anti-seismic bridge engineering, and can solve problems such as the mass ratio μ not meeting the design conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

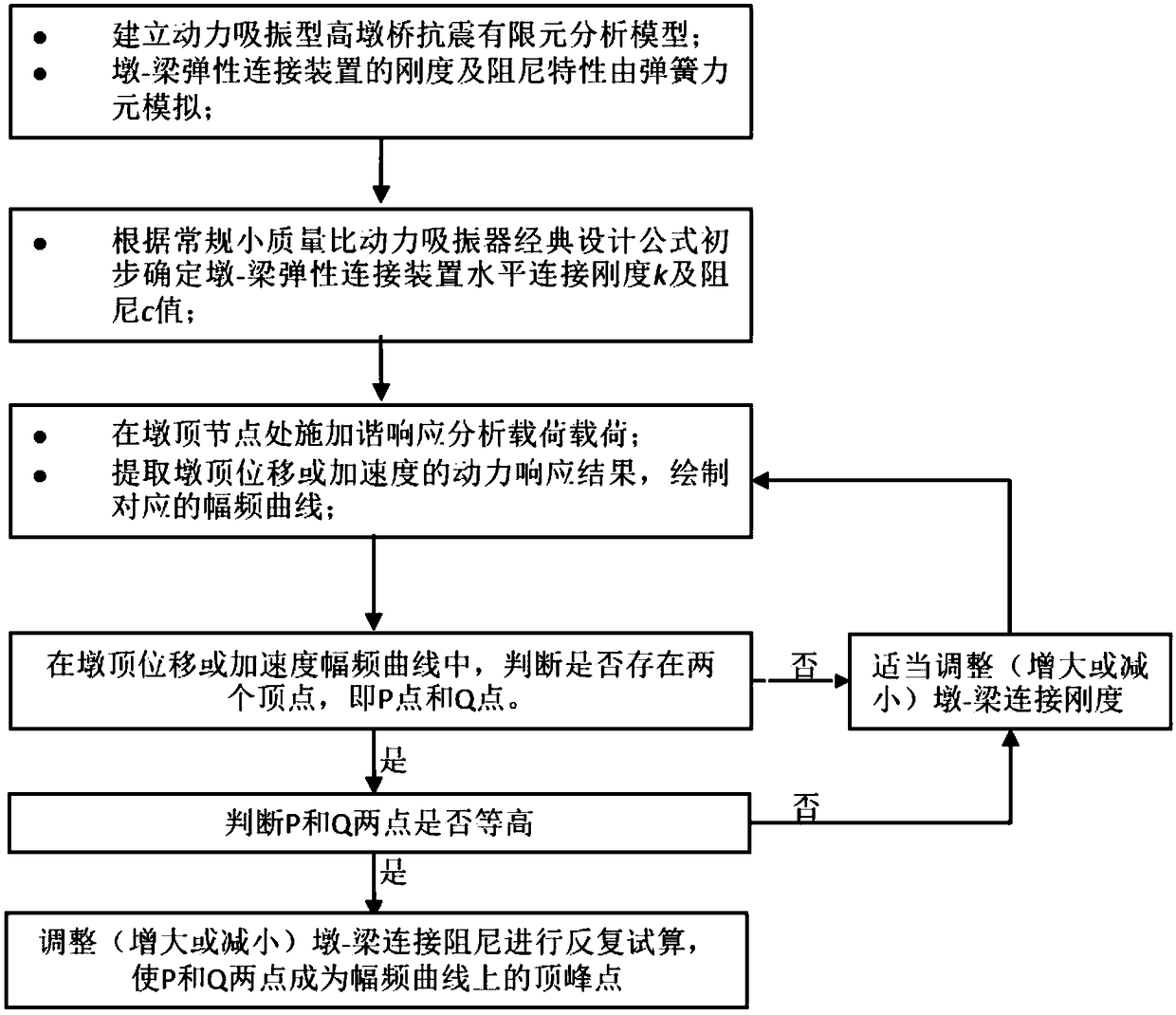

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

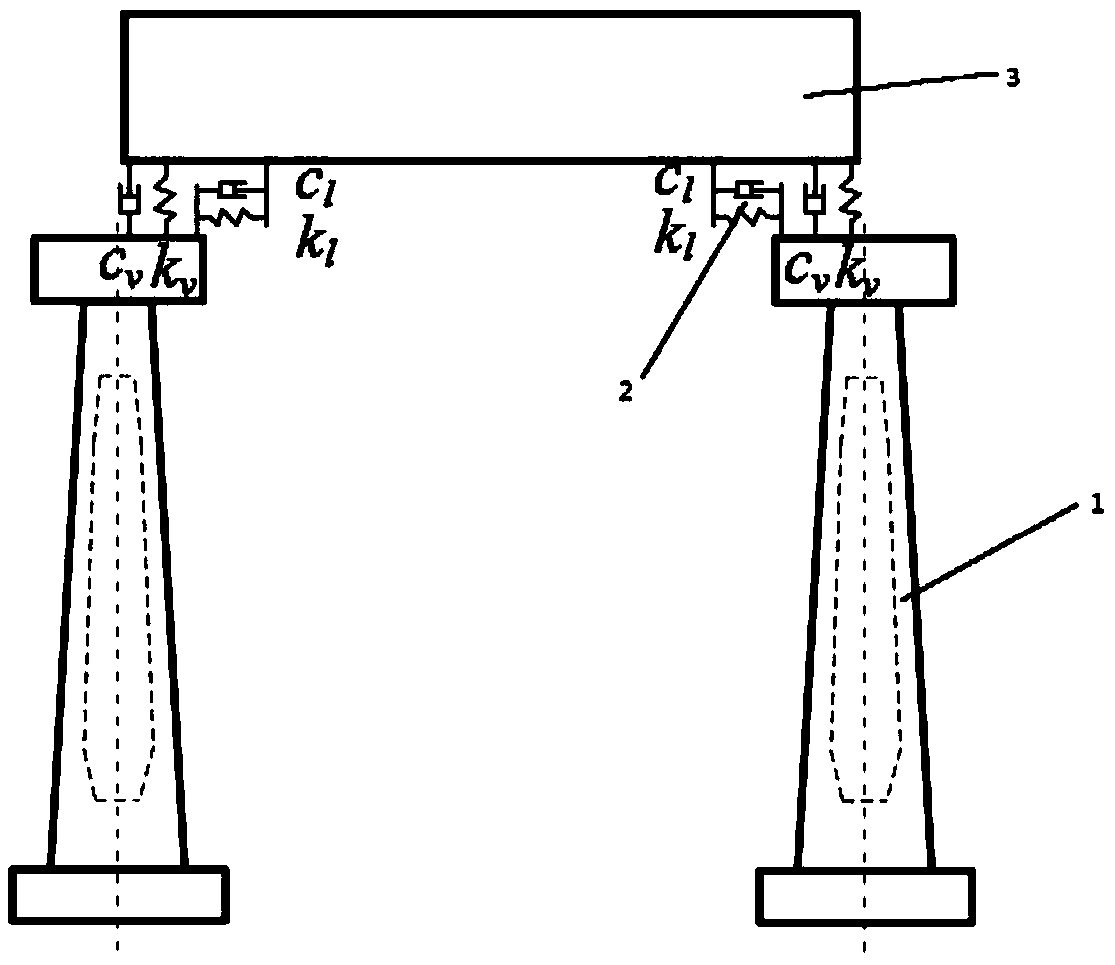

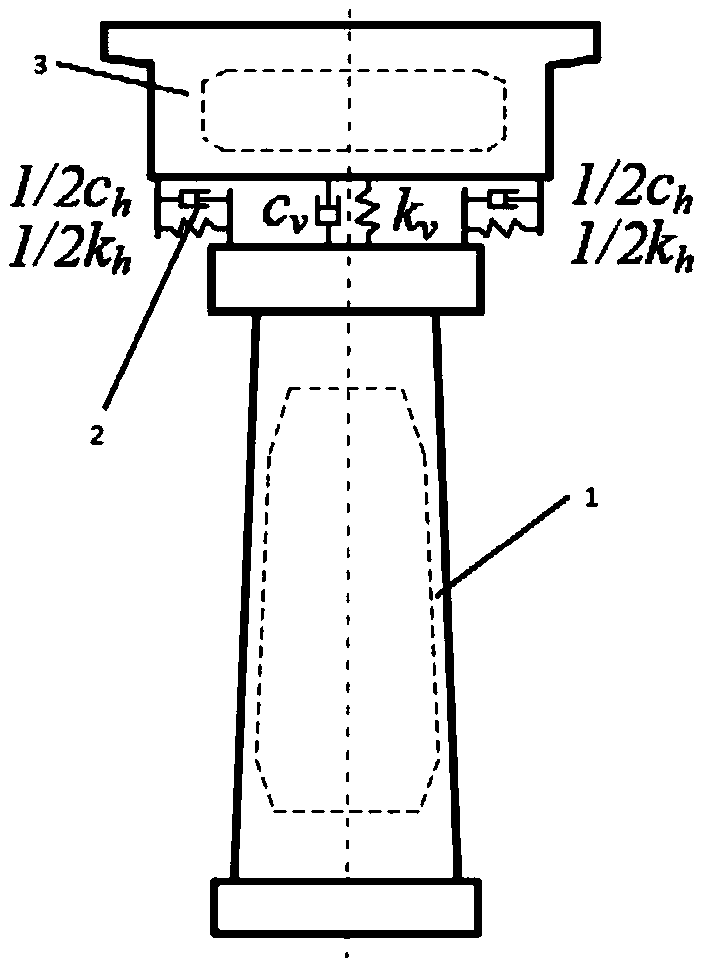

[0054] The research objects are the variable cross-section round-end hollow pier 1 and the commonly used 32.6m double-track four-piece simply supported T-beam 3 in railway double-track high-pier girder bridges. Among them, the appearance size of the round end section of the pier top is 10.6m×5.4m, and the length increases linearly from the top of the pier to the bottom of the pier, with a change rate of 1:40. A finite element analysis model of a dynamic vibration-absorbing high-pier girder bridge is established. The stiffness and damping characteristics of the pier-beam elastic connection device 2 are simulated by the spring force element. The bridge model has a total of 3 spans. The finite element model of the bridge pier is simulated by the beam element, the pier 1 is C30 concrete, and the pier height is 60m. The plastic deformation of the bridge is not considered, and it is assumed that the deformation of the bridge remains within the elastic range throughout the earthquake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com