Wire for multi-point wiring and processing method thereof

A technology of electric wire processing and electric wire, which is applied in the field of electric wire and its processing for multi-point wiring, to achieve the effect of improving efficiency, good connection strength, improving practical physical strength and convenience of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

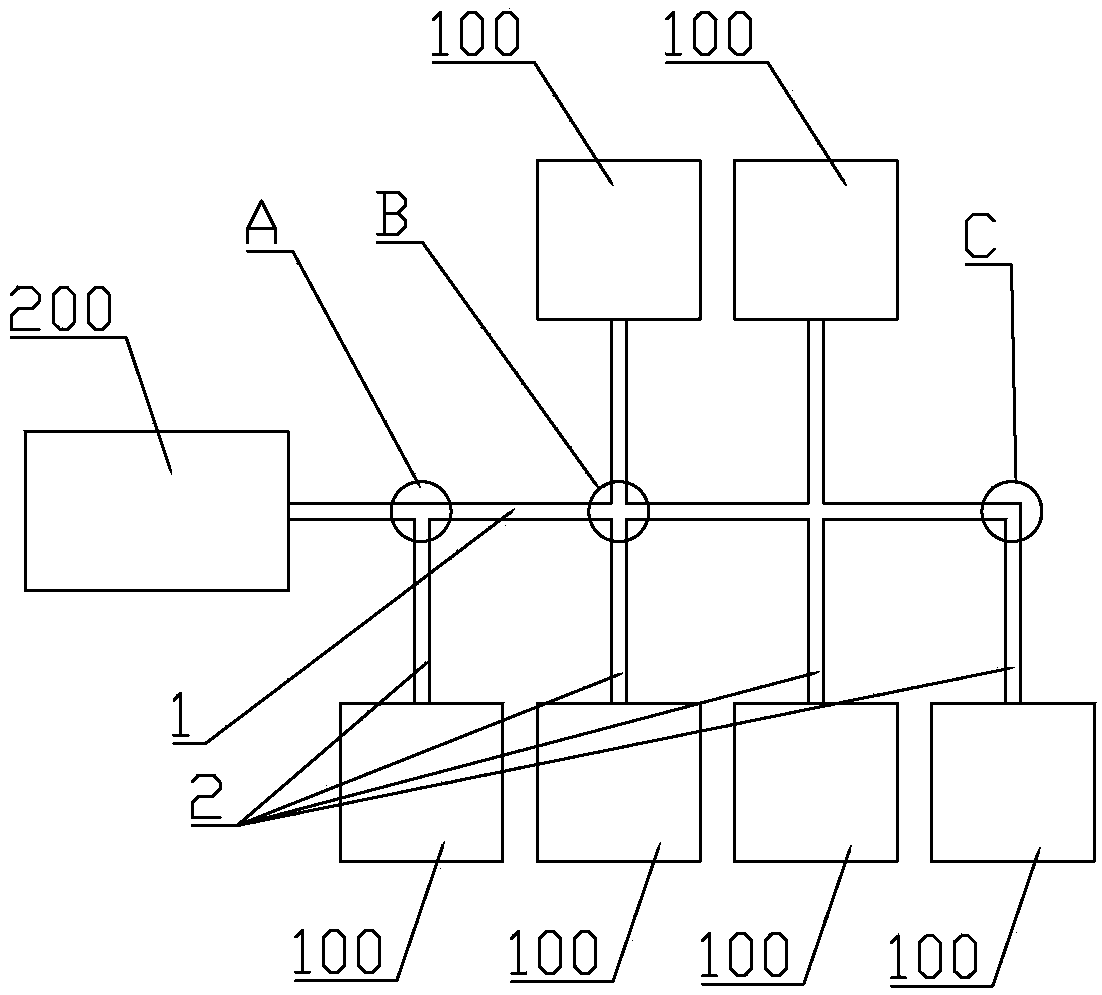

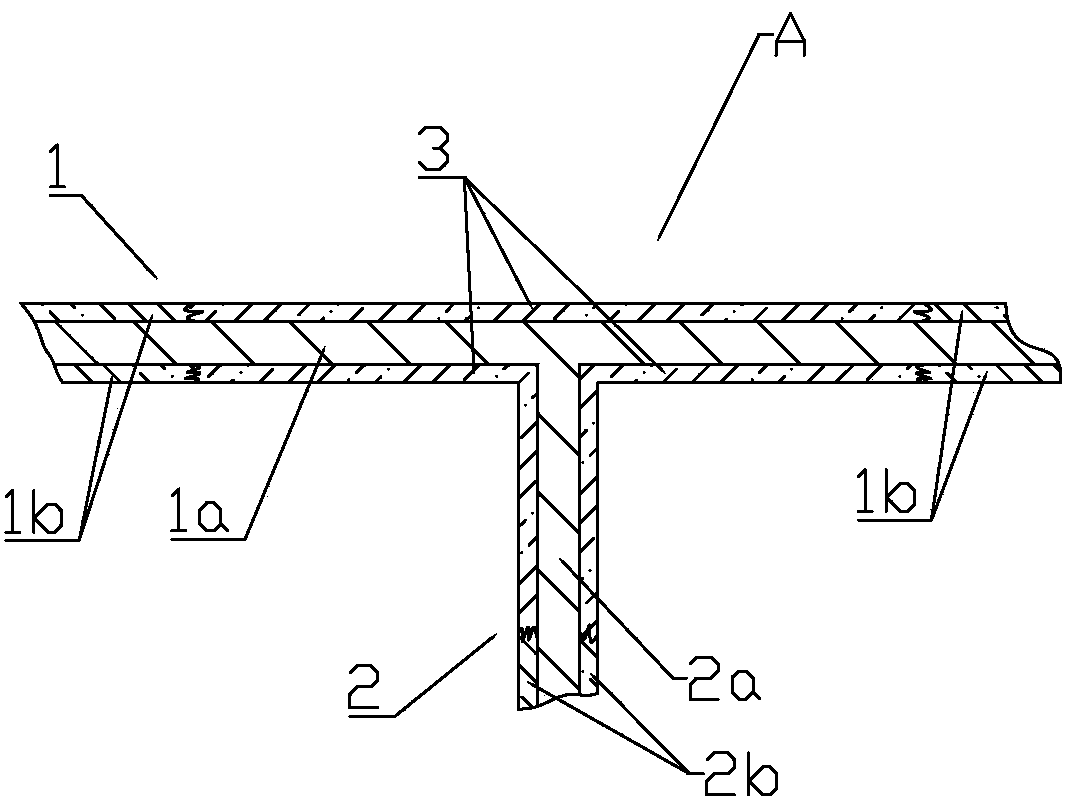

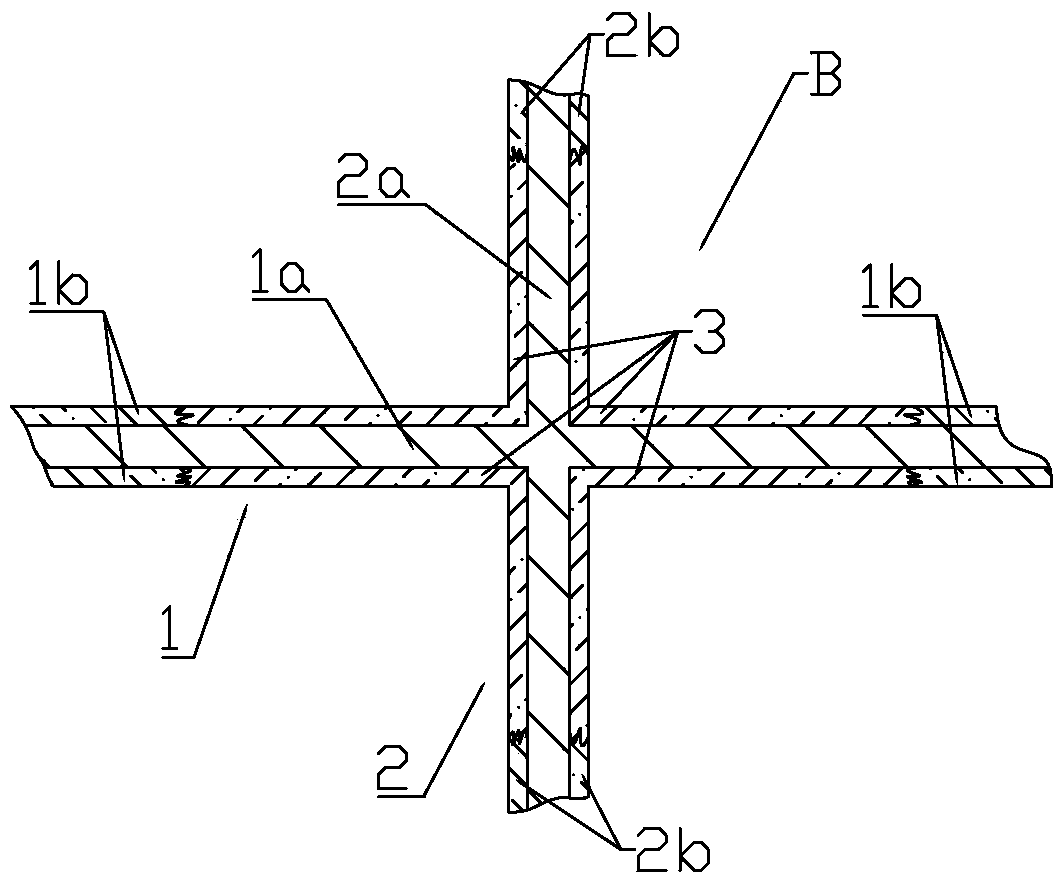

[0042] Embodiment 1, with reference to Figure 1-4, a kind of electric wire for multi-point connection in embodiment 1, comprises main electric wire 1 and branch electric wire 2, and main electric wire 1 is made of the first core wire 1a and the first insulation layer 1b that covers it outside, and branch electric wire 2 is made of The second core wire 2a is composed of a second insulating layer 2b covering it. The number of the main wire 1 is one, and the number of the branch wires 2 is four. Wherein, the first insulating layer 1b is peeled off at one end and three places in the middle of the main electric wire 1 to expose the first core wire 1a. One end of the two branch wires 2 is stripped off the second insulation layer 2b, exposing the second core wire 2a; the middle part of the other two branch wires 2 is stripped off the second insulation layer 2b, exposing the second core wire 2a . The exposed second core wires 2a of the four branch wires 2 are respectively welded t...

Embodiment 2

[0045] Embodiment 2, with reference to Figure 5 , a kind of electric wire for multi-point wiring in embodiment 2 has the same welded connection structure compared with embodiment 1, and the specific difference with the insulating coating structure is: the main wire 1 is arranged horizontally, and the main wire 1 is arranged vertically from the left To the right are four branch wires 2, the middle of one wire 2 is welded to one end of the main wire 1; the end of one wire 2 is welded to the other end of the main wire 1, and the ends of the two wires 2 are welded with the middle of the main wire 1. The main wire 1 is a hard wire, that is, the above-mentioned BV plastic copper wire; the branch wire 2 is a soft wire, specifically a BVR wire, a copper core PVC insulated flexible wire, and a hard wire and a soft wire are used for welding and connection. On the one hand, it is convenient for storage and transportation, and on the other hand, it has good connection physical strength,...

Embodiment 1 and 2

[0046] Embodiments 1 and 2 have the following advantages: the electric wires described in the embodiments are connected by welding the main electric wire 1 and the branch electric wire 2, while having good connection strength, the main electric wire 1 and the branch electric wire 2 can be seamlessly combined as one, The resistance value of the welding connection is equivalent to the resistance value of the straight-line wire, which will not cause local heating due to excessive load, and improve the safety and stability of the electrical connection. It is easy to cause the instability of electrical connection due to loosening, and even the problems of partial discharge and high partial resistance. In the embodiment, the welded connection of the electric wires is re-covered with the third insulating layer 3, and the third insulating layer 3 can cooperate well with the original first insulating layer 1b and the second insulating layer 2b to achieve a good waterproof and insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com