High voltage to low voltage TSC device

A step-down transformer, low-voltage technology, applied in harmonic reduction devices, circuit devices, AC network voltage adjustment and other directions, can solve the problems of high maintenance cost, large floor space, large impact inrush current, etc., achieve ideal compensation effect and save energy Small footprint, no inrush impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to be able to understand the above objectives, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

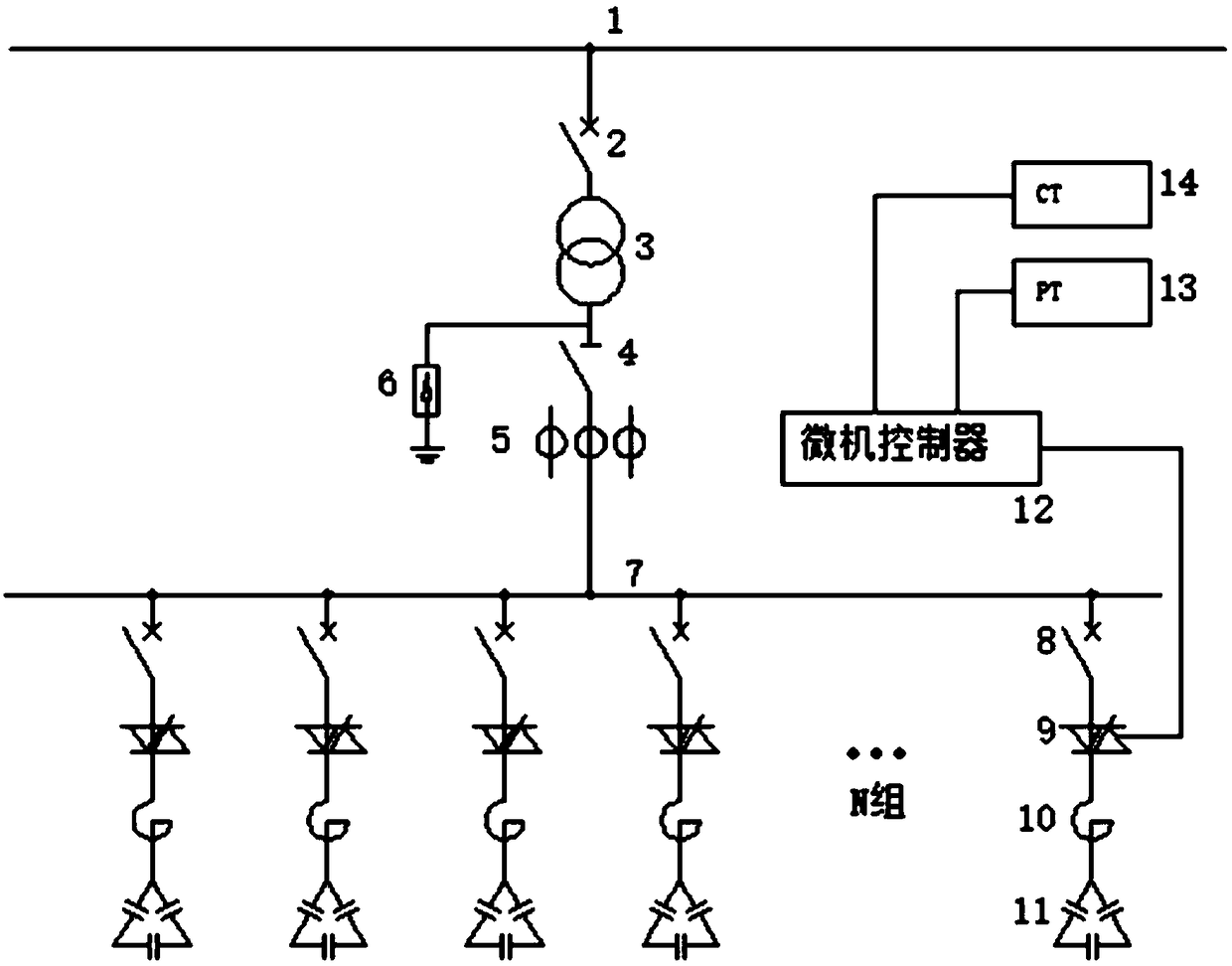

[0014] The high-voltage transformer low-voltage TSC device disclosed in the present invention includes: high-voltage bus, circuit breaker A, step-down transformer, isolating switch, current transformer, arrester, low-voltage bus, circuit breaker B, thyristor switch, series reactor, capacitor, and microcomputer controller , Sampling PT, sampling CT. It is characterized in that the inlet end of the circuit breaker A (2) is connected to the high voltage bus (1), the outlet end of the circuit breaker A (2) is connected to the inlet end of the step-down transformer (3), and the step-down transformer (3) The outlet end of) is connected to the inlet end of the isolating switch (4), and is also connected to the inlet end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com