A kind of preparation method of dogwood brewing powder

A technology of Cornus officinalis and preparation powder, which is applied in the field of preparation of Cornus officinalis preparation, can solve the problems such as unsatisfactory deastringency effect and less fruit juice of Cornus officinalis, and achieve the improvement of in-depth development value and economic value, good taste and nutritional active ingredients high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of Cornus officinalis powder, comprising the following steps:

[0028] (1) Take the ripe fresh fruit of Cornus officinalis, after cleaning, freeze it at -2°C for 25 hours, then directly add the fresh fruit of Cornus officinalis after freezing into hot water at 75°C, boil for 8 minutes, remove the core, and obtain the pulp of Cornus officinalis;

[0029] (2) Mix cornus officinalis pulp and water at a weight ratio of 1:4.5, then add it to a wall breaker for crushing and homogenizing treatment, and then filter through an 80-mesh filter cloth to obtain filtrate A;

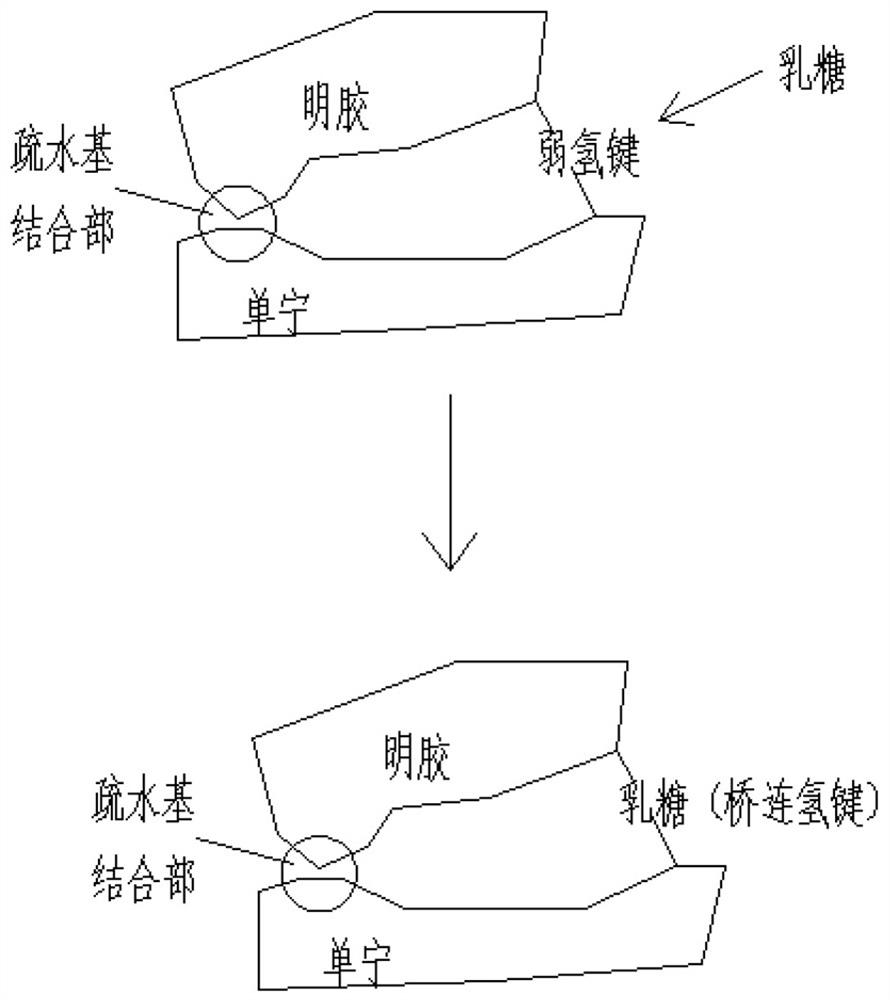

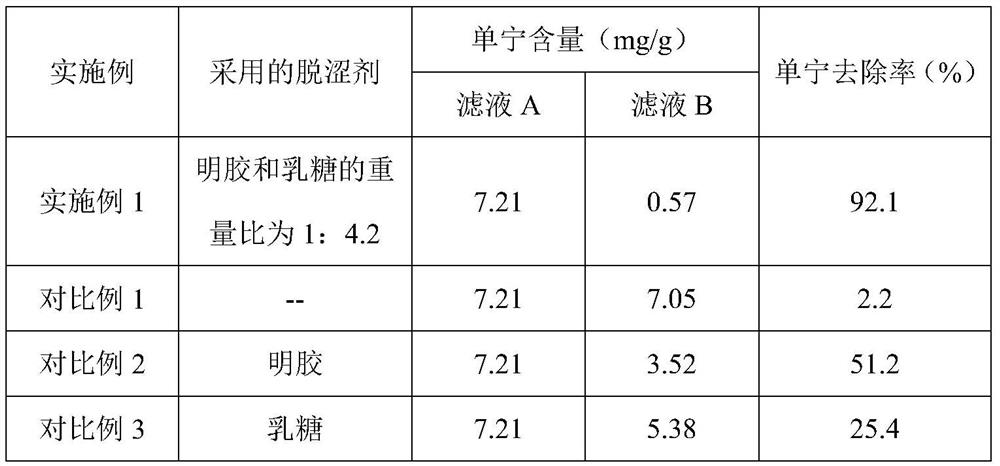

[0030] (3) Add astringent-removing agent to filtrate A, shake at 40°C for 7 hours, and then pass through a 250-mesh filter cloth to obtain filtrate B; wherein, the weight ratio of the filtrate A to the astringent-removing agent is 1:0.0016, and the astringent-removing agent The astringent is a mixture of gelatin and lactose, and the weight ratio of gelatin and lactose in the astringent is 1:...

Embodiment 2

[0033] A preparation method of Cornus officinalis powder, comprising the following steps:

[0034] (1) Take mature fresh fruit of Cornus officinalis, after cleaning, freeze it at -5°C for 20 hours, then directly add the fresh fruit of Cornus officinalis after freezing to boiling water at 80°C for 5 minutes, remove the core, and obtain the pulp of Cornus officinalis;

[0035] (2) Mix cornus officinalis pulp and water at a weight ratio of 1:3, add it to a wall breaker for crushing and homogenization, and then filter through a 100-mesh filter cloth to obtain filtrate A;

[0036] (3) Add astringent-removing agent to filtrate A, shake at 30°C for 9 hours, and then pass through a 300-mesh filter cloth to obtain filtrate B; wherein, the weight ratio of the filtrate A to the astringent-removing agent is 1:0.0012, and the astringent-removing agent The astringent is a mixture of gelatin and lactose, and the weight ratio of gelatin and lactose in the astringent is 1:3.5;

[0037] (4) Sp...

Embodiment 3

[0039] A preparation method of Cornus officinalis powder, comprising the following steps:

[0040] (1) Take mature fresh fruit of Cornus officinalis, after cleaning, freeze it at 0°C for 30 hours, then directly add the fresh fruit of Cornus officinalis after freezing into hot water at 70°C, boil for 10 minutes, remove the core, and obtain the pulp of Cornus officinalis;

[0041] (2) Mix cornus officinalis pulp and water at a weight ratio of 1:6, then add it to a wall breaker for crushing and homogenization, and then filter through a 50-mesh filter cloth to obtain filtrate A;

[0042] (3) Add astringent-removing agent to filtrate A, shake at 45°C for 6 hours, and then pass through a 200-mesh filter cloth to obtain filtrate B; wherein, the weight ratio of the filtrate A to the astringent-removing agent is 1:0.0018, and the astringent-removing agent The agent is a mixture of gelatin and lactose, and the weight ratio of gelatin and lactose in the astringent removing agent is 1:4.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com