Personalized-wearing prosthesis and manufacturing method thereof

A technology of prosthetics and residual limbs, applied in the field of prosthetics, can solve problems such as high cost, poor experience, and uncomfortable wearing, and achieve the effects of simple structure, improved shock resistance, and improved wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

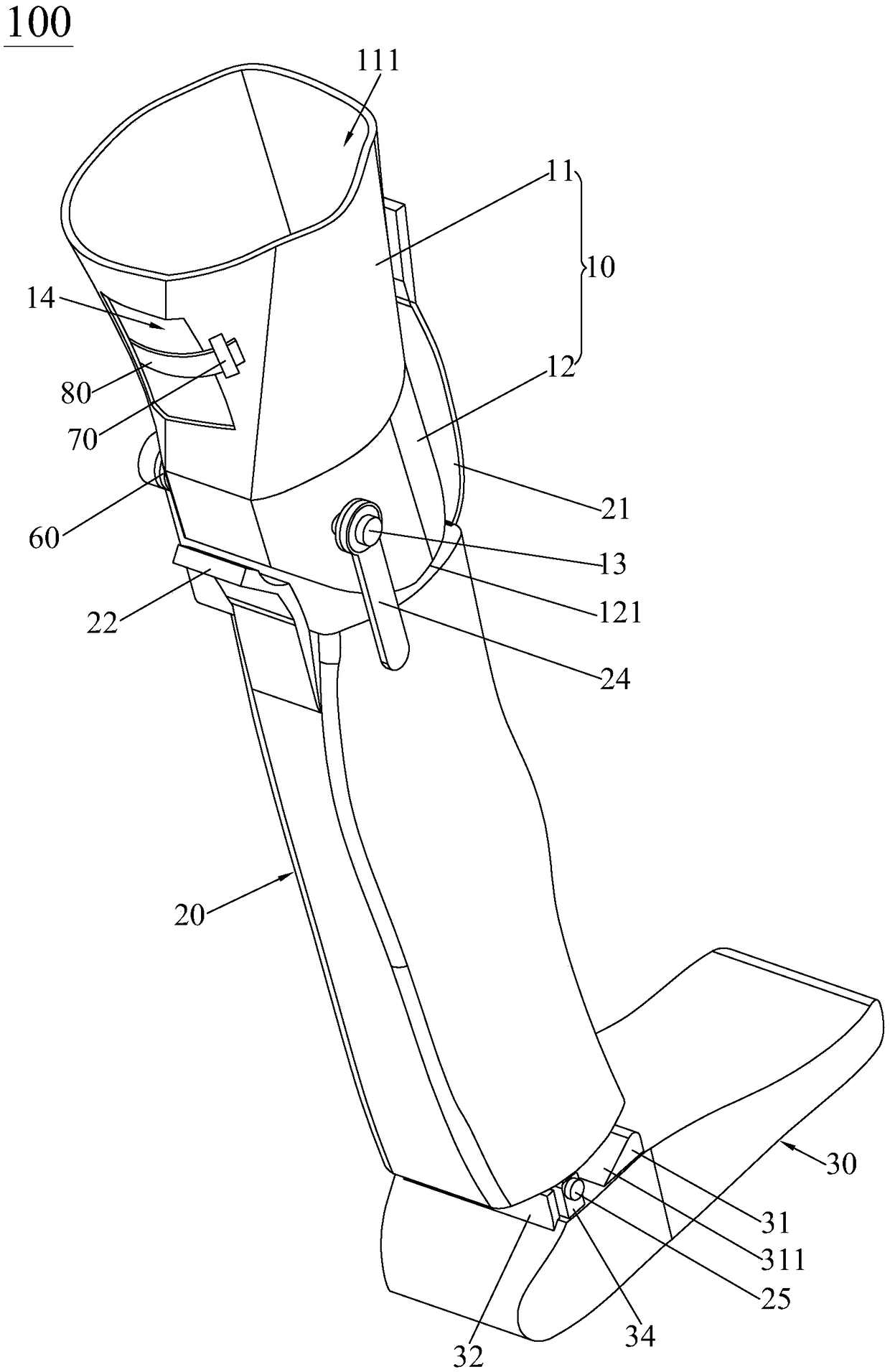

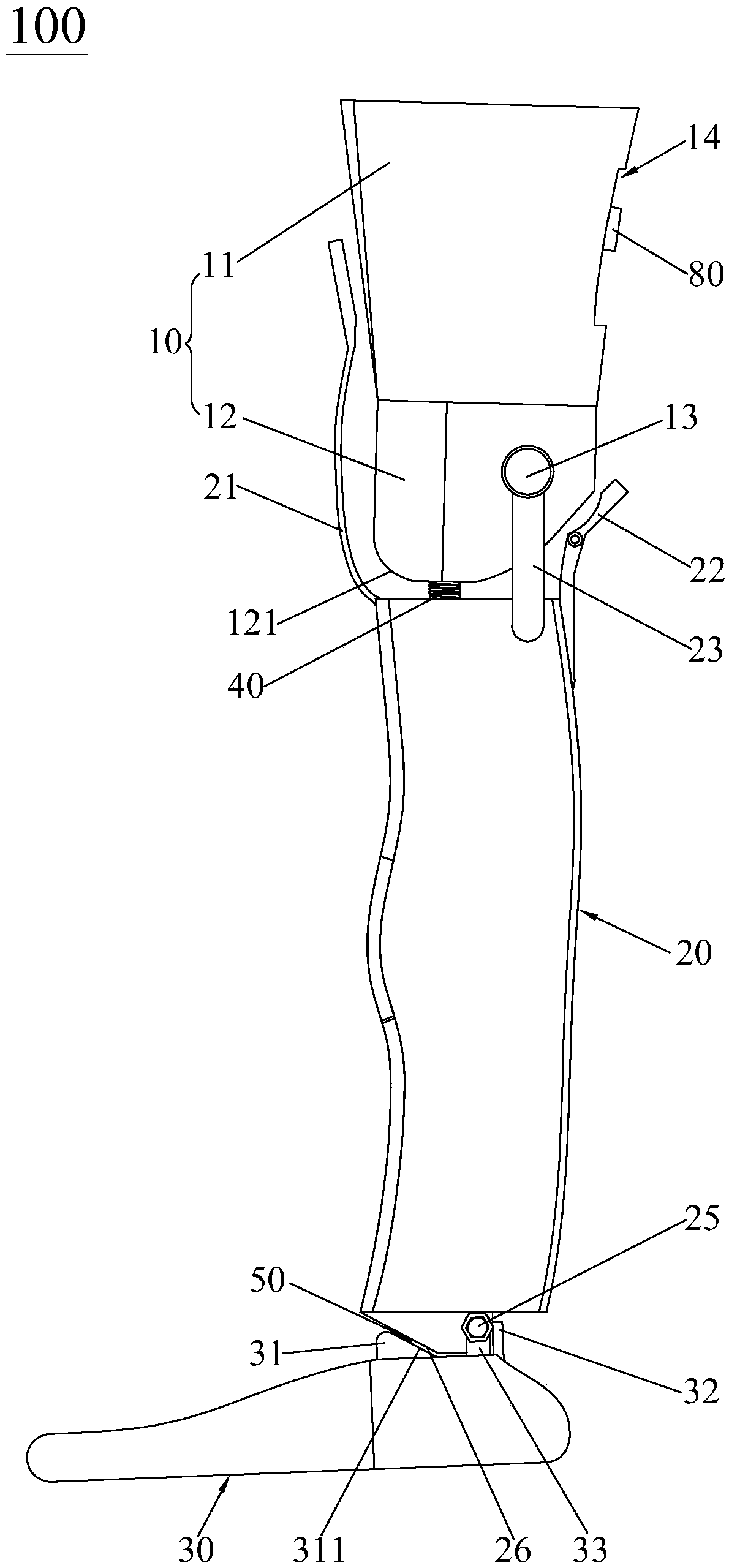

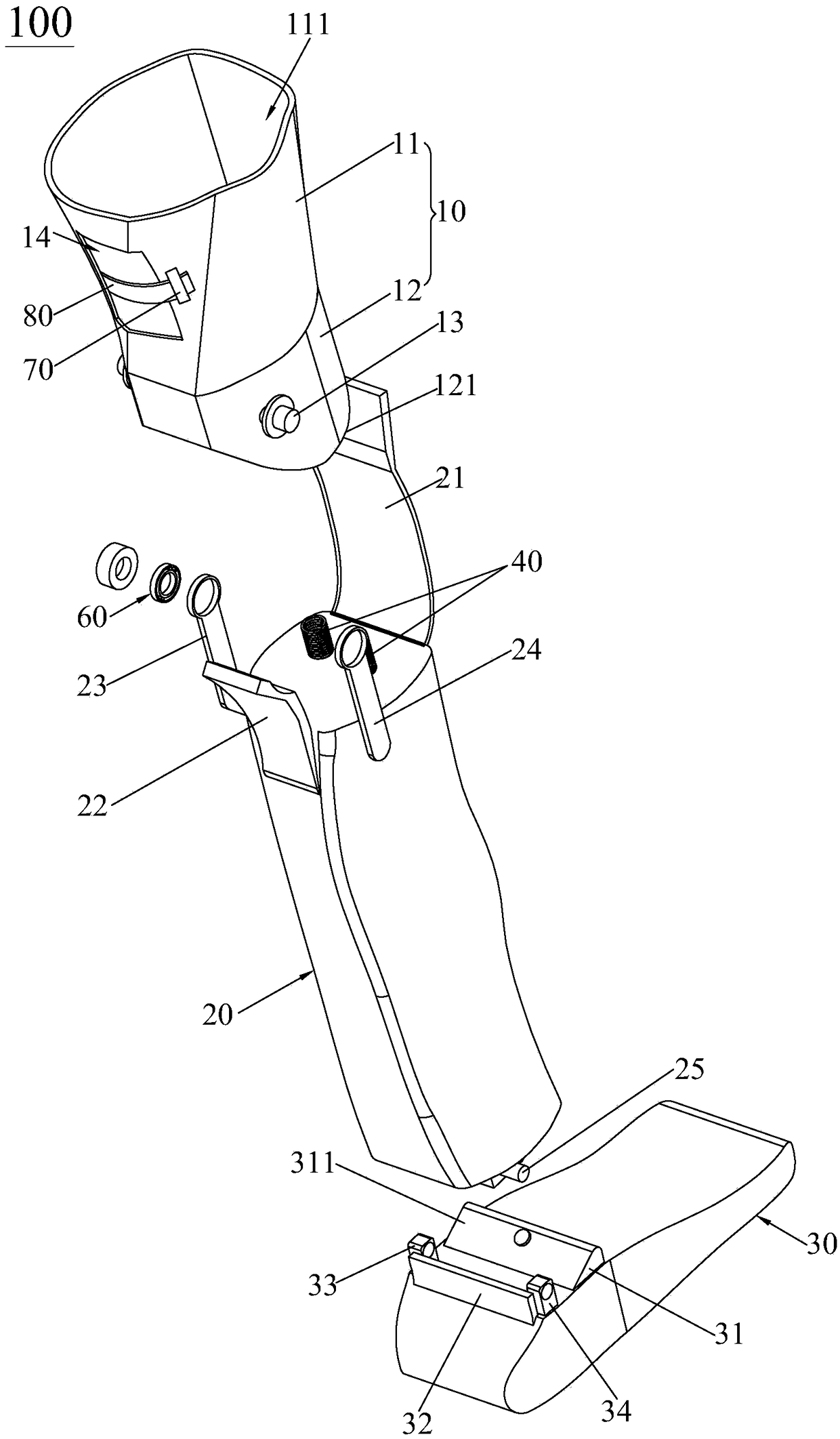

[0032] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

[0033] see Figure 1 to Figure 4, the personalized wearable prosthesis 100 of the present invention includes a thigh prosthesis 10 , a calf prosthesis 20 , a foot prosthesis 30 , a first spring 40 and a second spring 50 . The thigh prosthesis 10 includes a flexible upper part 11 and a rigid lower part 12. For example, the upper part 11 can adopt various flexible materials that are easy to wear, while the lower part 12 adopts carbon fiber that provides sufficient strength, and can also be used as much as possible under the condition of obtaining higher strength. To reduce the weight as much as possible, preferably, the thigh prosthesis 10 is a one-piece structure printed by 3D, so as to facilitate the manufacture of the thigh prosthesis 10, so that the personalize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com