Filtering net component with self-cleaning function

A self-cleaning, functional technology, applied in the field of filter screen components with self-cleaning function, can solve the problems of large wet dust, inability to handle, and dust particles cannot be adsorbed, so as to improve the automation of equipment, prevent the growth of bacteria, and prevent dust from flying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] as attached figure 1 To attach Figure 6 shown

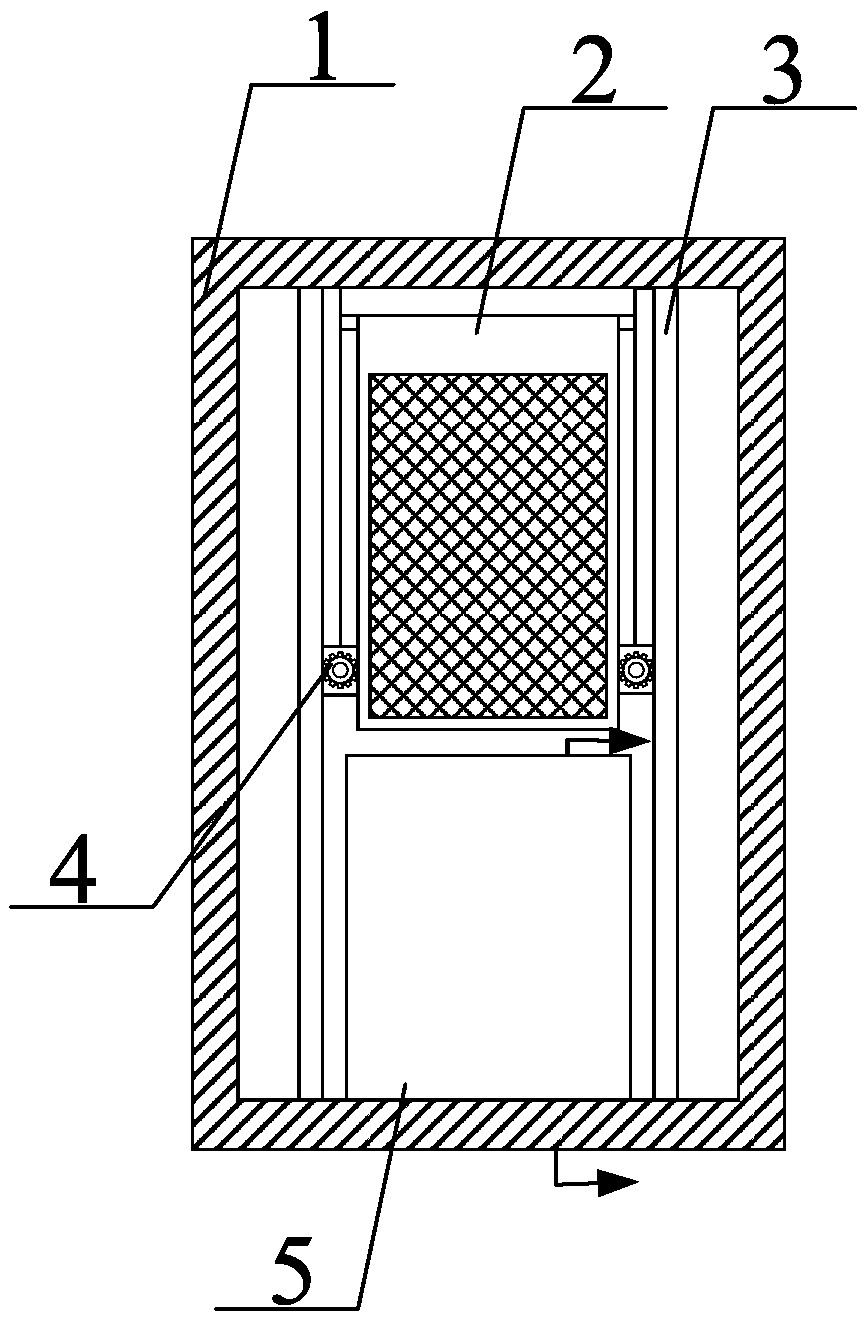

[0025] The present invention provides a filter screen assembly with self-cleaning function, which includes a purifier housing 1, a filter screen mechanism 2, an embedded plate 3, a drive mechanism 4 and a cleaning mechanism 5, and the two sides of the filter screen mechanism 2 are connected by screws. The embedded plate 3 is fixed; the embedded plate 3 adopts 2 pieces, which are respectively arranged on the left side and the right side of the filter screen mechanism 2, and its upper end and lower end are all clamped with the purifier housing 1; the drive mechanism 4 passes through The bolt is fixed on the inner side of the embedded board 3, and is connected with the circuit of the purifier through a wire; the cleaning mechanism 5 is arranged under the filter screen mechanism 2, and is connected with the circuit of the purifier through a wire.

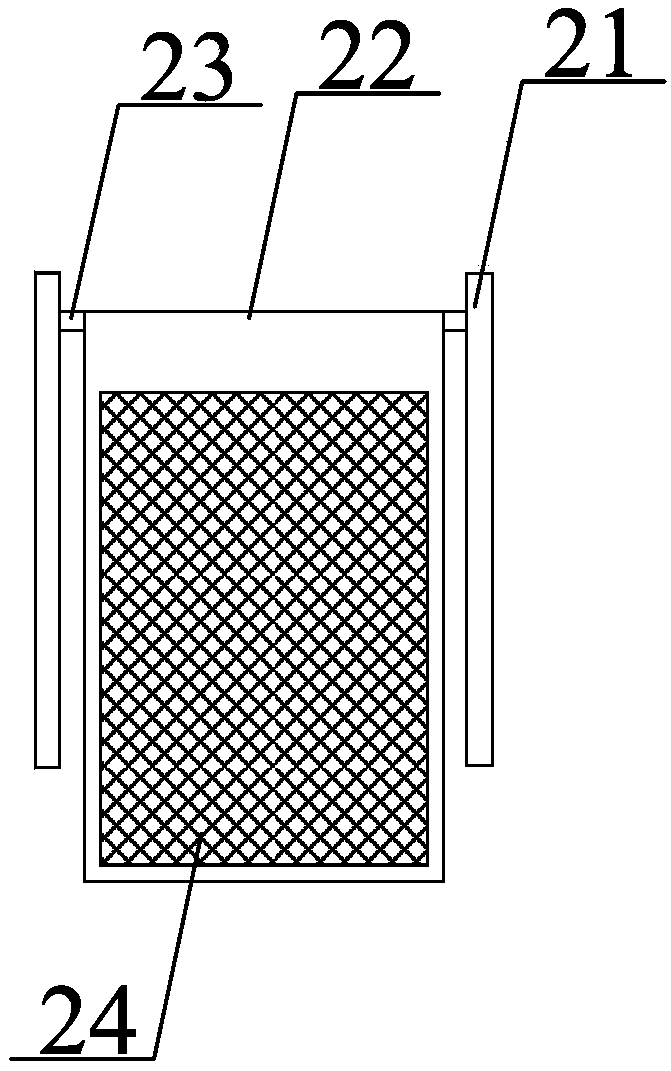

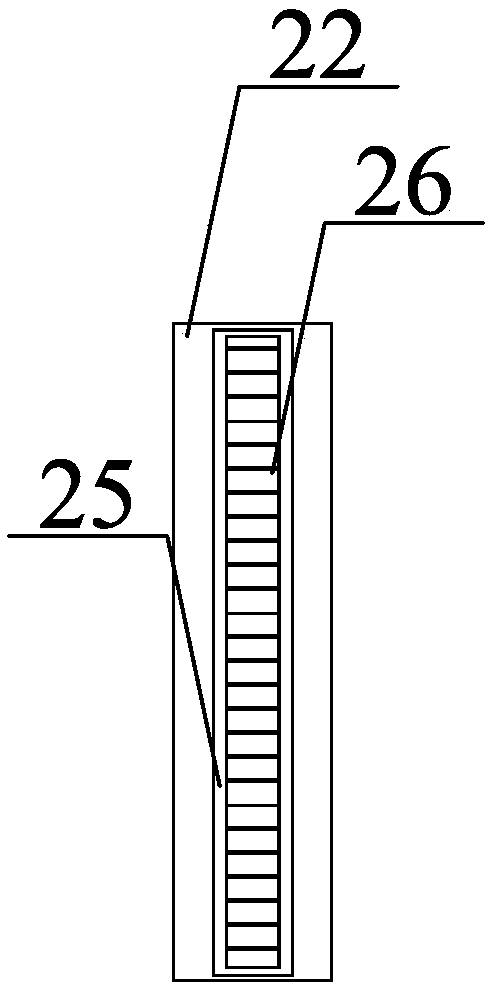

[0026] Described filter screen mechanism 2 comprises slide bar 21, filter sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com