Winnowing piece

A technology of air selection and selection, which is applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problem of inability to remove lighter impurities from seeds, and achieves simple structure and production cost. Low, clean separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

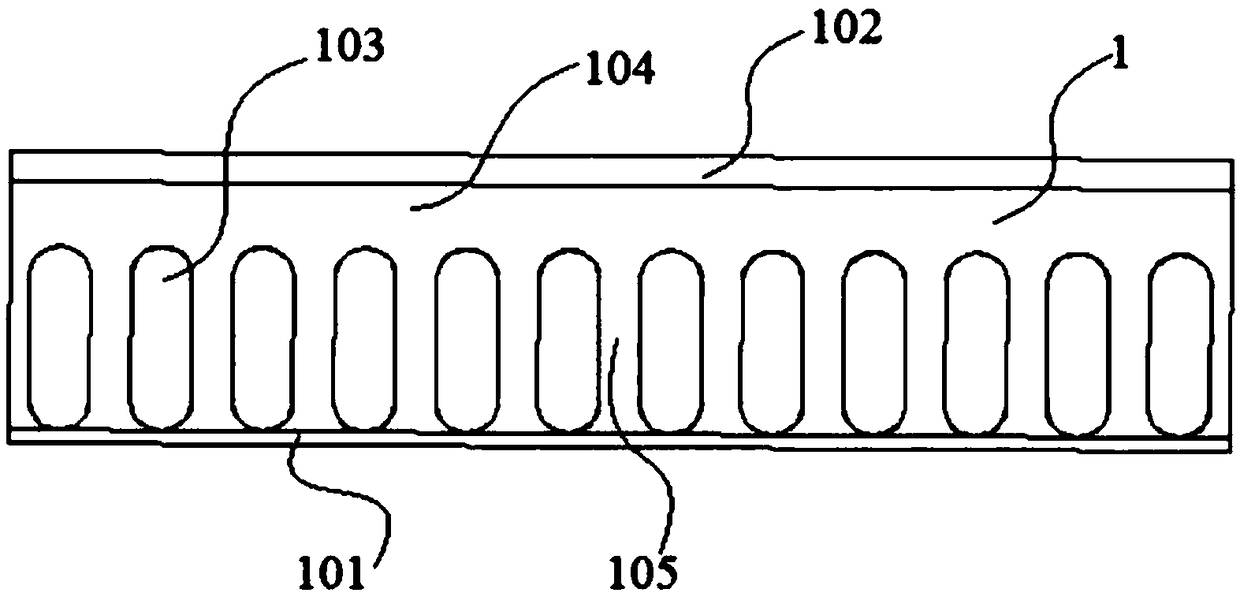

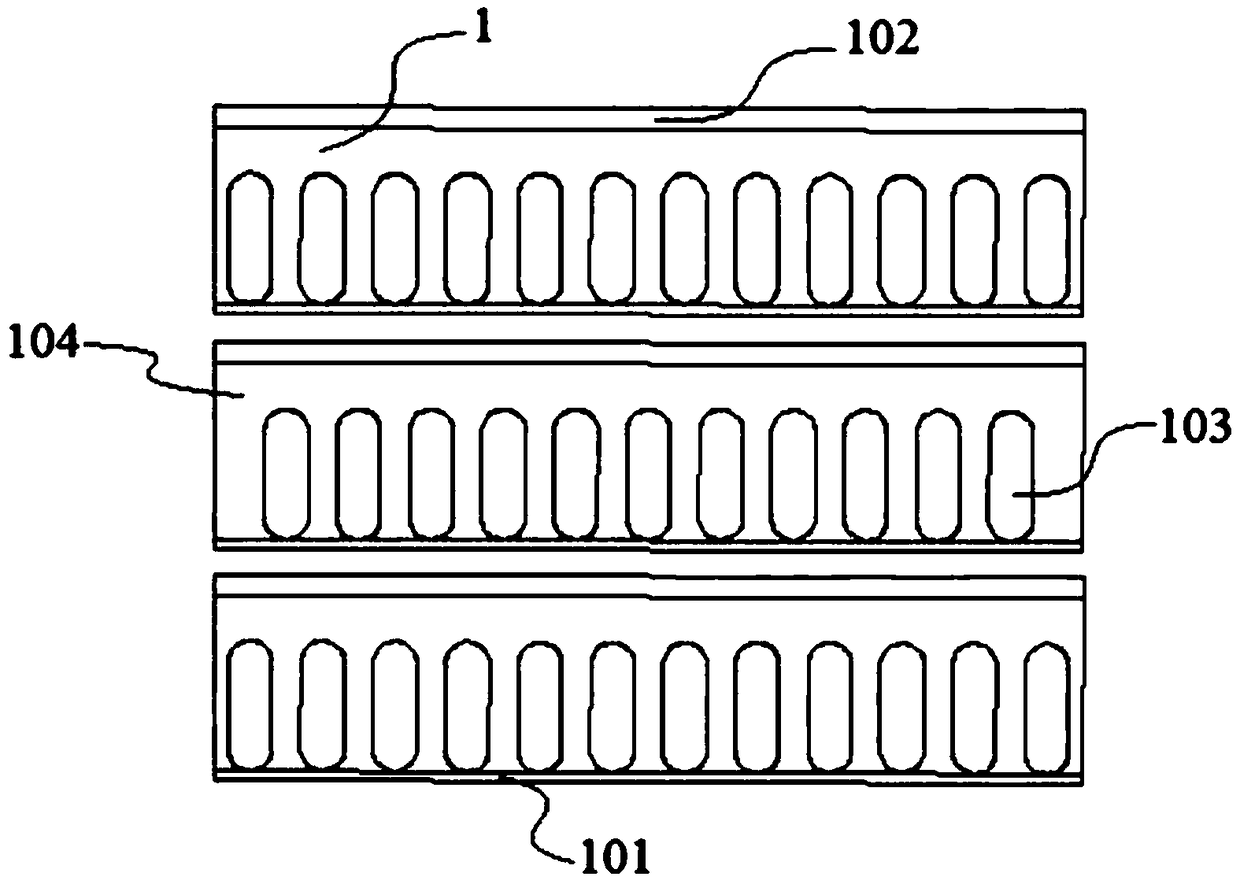

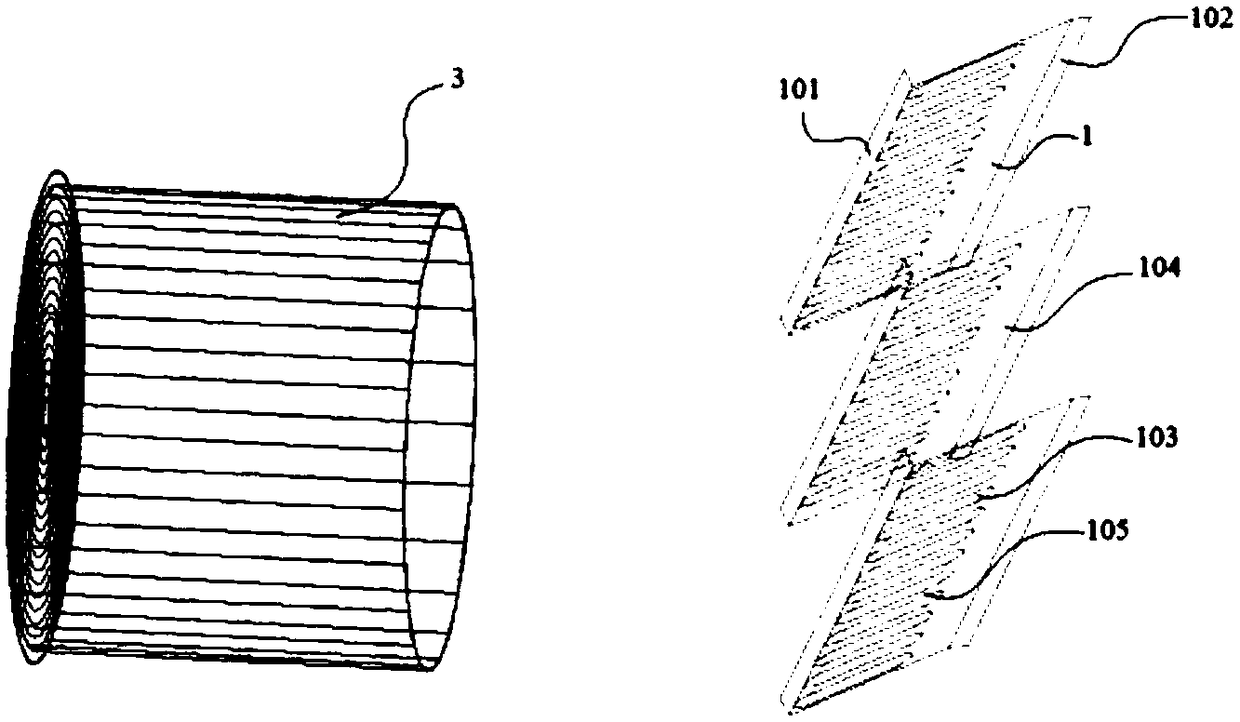

[0048] A wind option, combined with Figure 1-4 , The winnowing part comprises winnowing board 1, and winnowing board 1 is provided with winnowing hole 103, and the positions of winnowing hole 103 on two winnowing boards 1 adjacent up and down mutually stagger.

[0049] The air selection part includes several air selection boards 1, which can be set according to the needs. The larger the distance between adjacent air selection boards 1, the more fully the contact with the material will be when the wind passes through the gaps between adjacent air selection boards 1. The more impurities are blown away, but the distance process makes it inconvenient for the air separation hole 103 on the next wind separation board 1 to gather the materials, and one wind separation board 1 will not be able to completely remove the impurities in the material, and the material bundle will inevitably be mixed There are impurities, so multiple air selection boards 1 of the air selection unit need to ...

Embodiment 2

[0051] A wind selection part of the present embodiment is similar to Embodiment 1, the difference is that the wind selection plate 1 includes a wind selection hole 103, a lower plate 101 and a middle plate 104, wherein the middle plate 104 and the lower plate 101 are sequentially connection, the middle plate 104 is provided with winnowing holes 103 .

[0052] The middle plate 104 is longer than the width of the upper plate 102 and the lower plate 101, and the material of the middle plate 104 is a stainless steel plate or a plate of other materials that can bear the falling force of the material, because the middle plate 104 bears the force of the falling material .

Embodiment 3

[0054] A wind option in this embodiment is similar to Embodiment 1, the difference is that it also includes an upper plate 102, the upper plate 102, the middle plate 104 and the lower plate 101 are connected in sequence, and the upper plate 102 and the middle plate 104 The angle between them is less than or equal to 180°, the material falls to the lower edge of the air selection hole 103, and will be scattered to the left side of the air selection part under the action of the lower edge, and the upper plate 102 plays a role in resisting the material from being scattered to the left side of the air selection part The function is to prevent the material from falling to the place other than the left side of the air selection part during the falling process, keep the site clean and tidy, completely separate the material and impurities, and realize the cleanliness of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com