Tray carrier module of smart tray sorting machine

A technology of sorting machines and trays, applied in sorting and other directions, can solve the problems of easy failure, inconvenient maintenance, and inability to meet the needs of high-efficiency sorting and distribution, and achieve easy installation or maintenance, easy use and operation, and easy maintenance The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

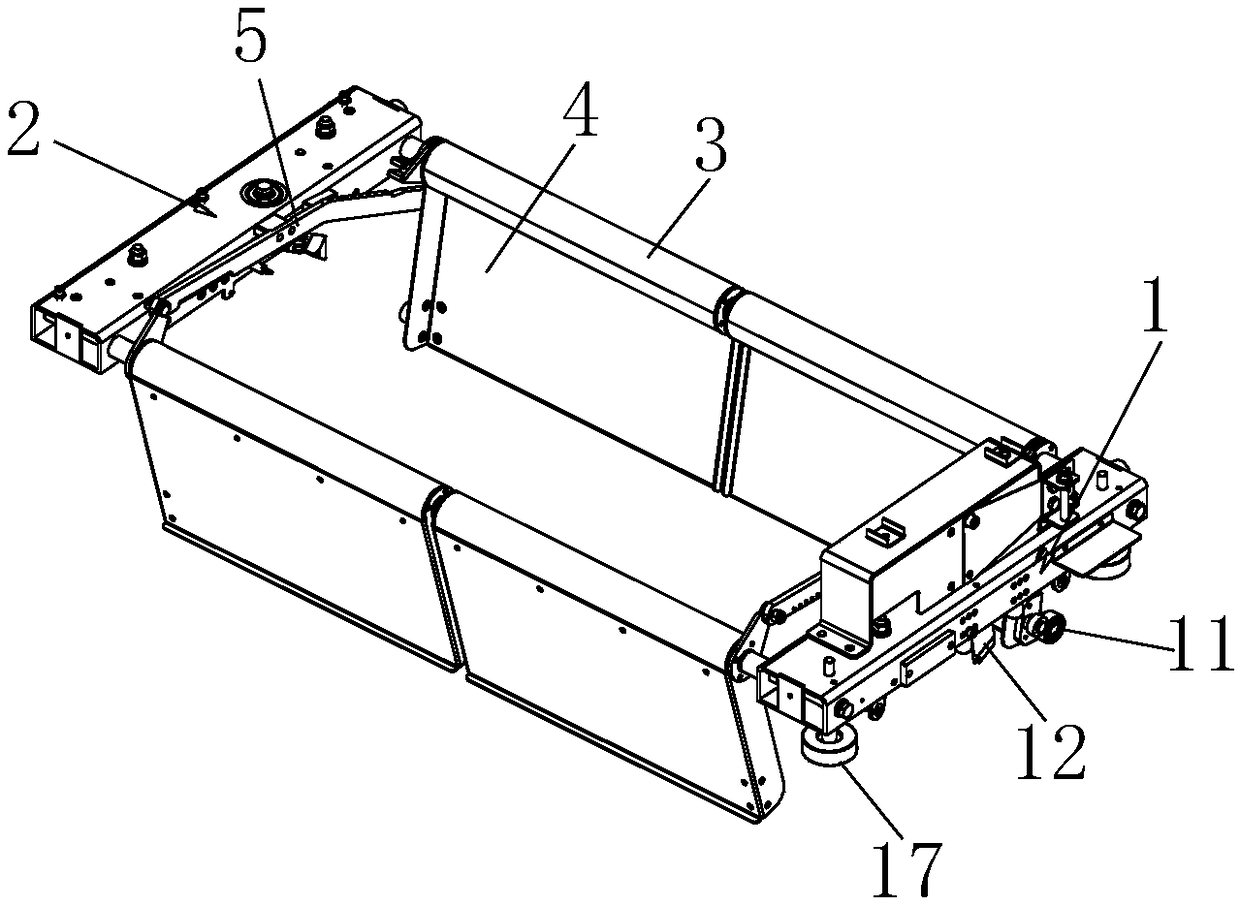

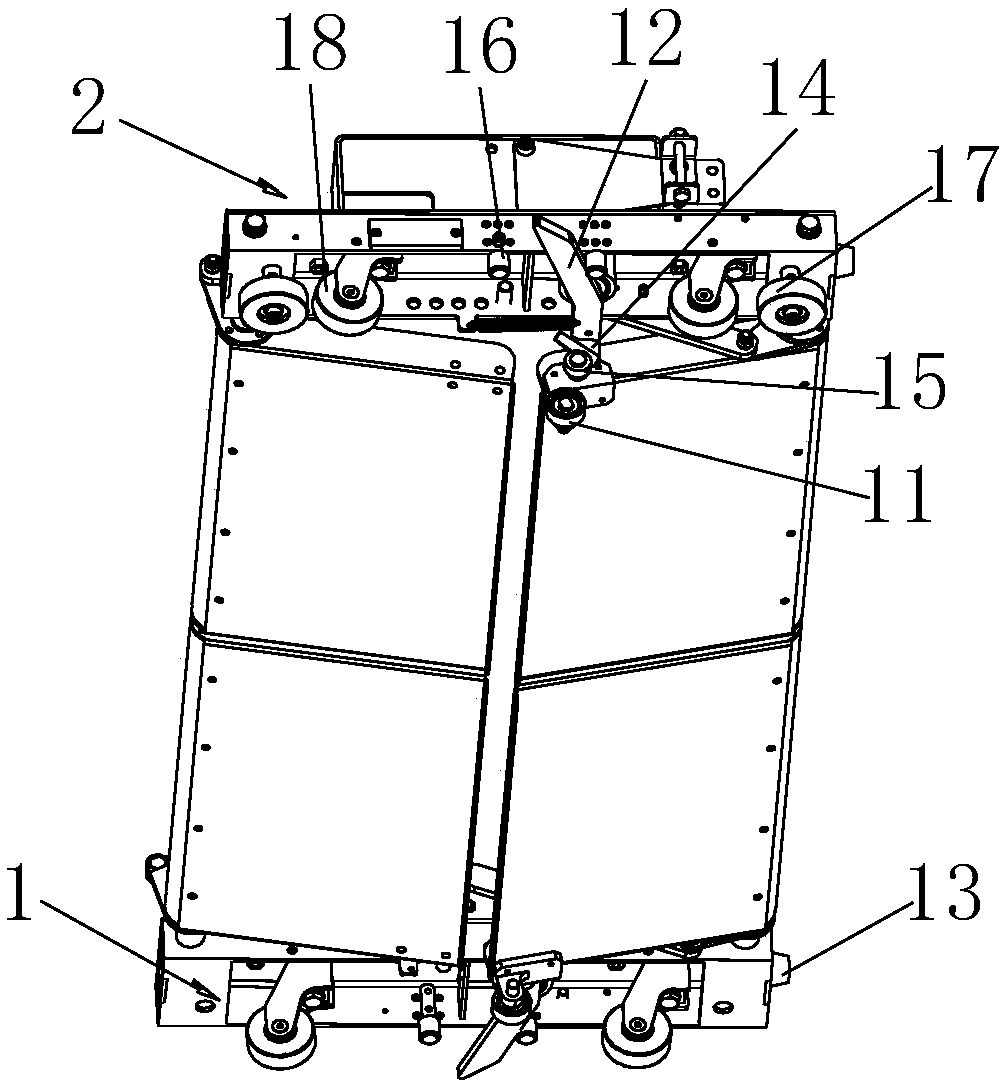

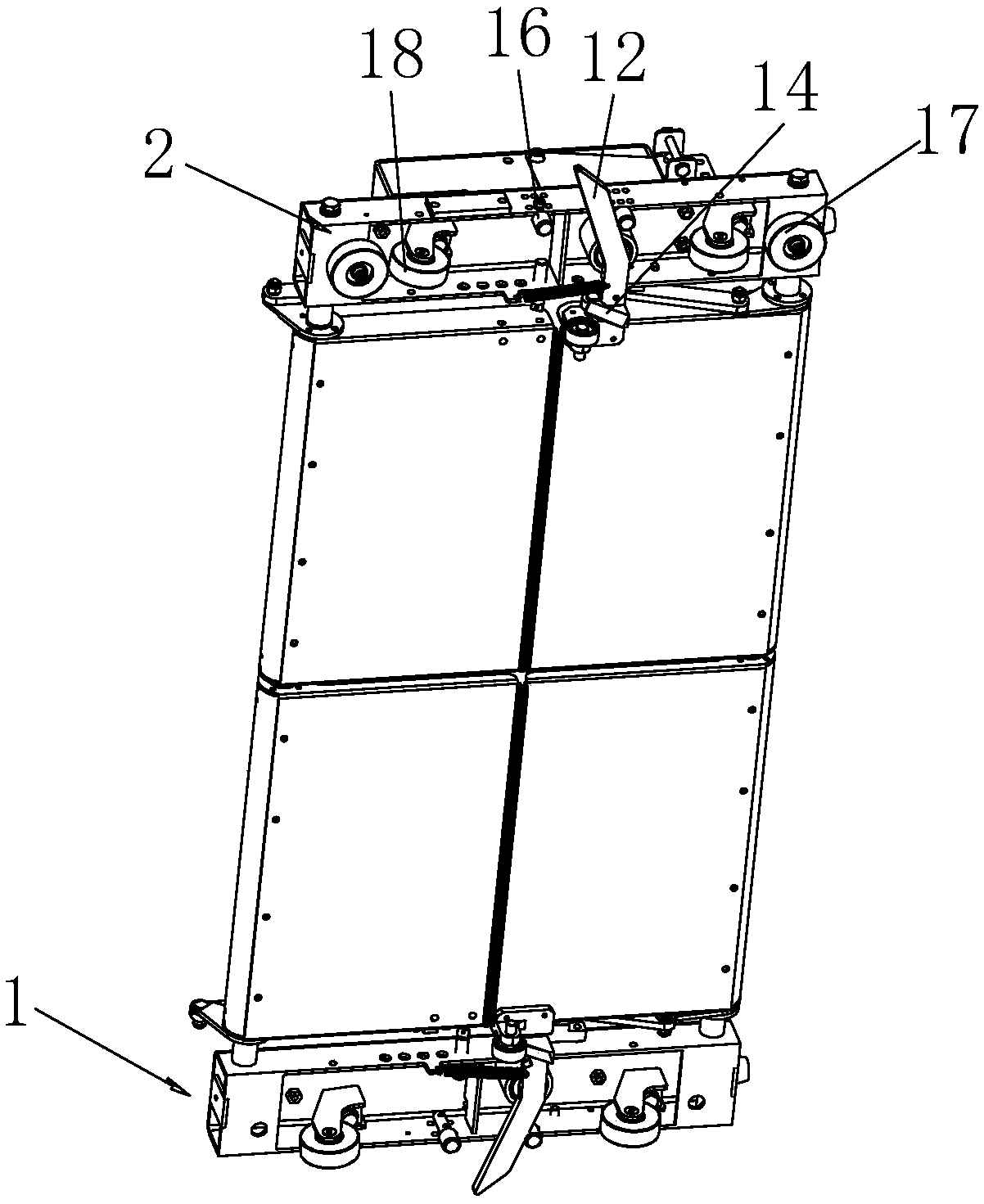

[0018] See Figure 1 to Figure 7 As shown: the present invention includes a synchronous mechanism 1, an unloading locking mechanism 2, a rotating shaft 3, and a tray 4. The synchronous mechanism 1 is provided with an unloading locking mechanism 2, and two symmetrically arranged The rotating shaft 3 is provided with a tray 4, the tray 4 is provided with a locking wheel 15 and a reset wheel 11, and the rotating shaft 3 is also provided with two short connecting rods 51, and a long connecting rod is hinged between the two short connecting rods 51 5. The long connecting rod 5 is provided with a return spring 52, and the lower end of the synchronization mechanism 1 is provided with a guide wheel 17 and a walking wheel 18. The lower end of the synchronization mechanism 1 also has a movable swing arm 12, and the lower end of the synchronization mechanism 1 is provided with a limit movable pendulum. The limit block 16 of arm 12 activity, one end of movable swing arm 12 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com