Stamping die for forming multi-profile surfaces of an automobile skylight guide rail and stamping method thereof

A technology for automotive sunroofs and stamping dies, applied in forming tools, manufacturing tools, metal processing, etc., can solve the problems that stamping dies cannot be stamped and formed at one time, unfavorable product quality control, large investment in machine tools, etc., and achieve high processing accuracy , Conducive to product quality control, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

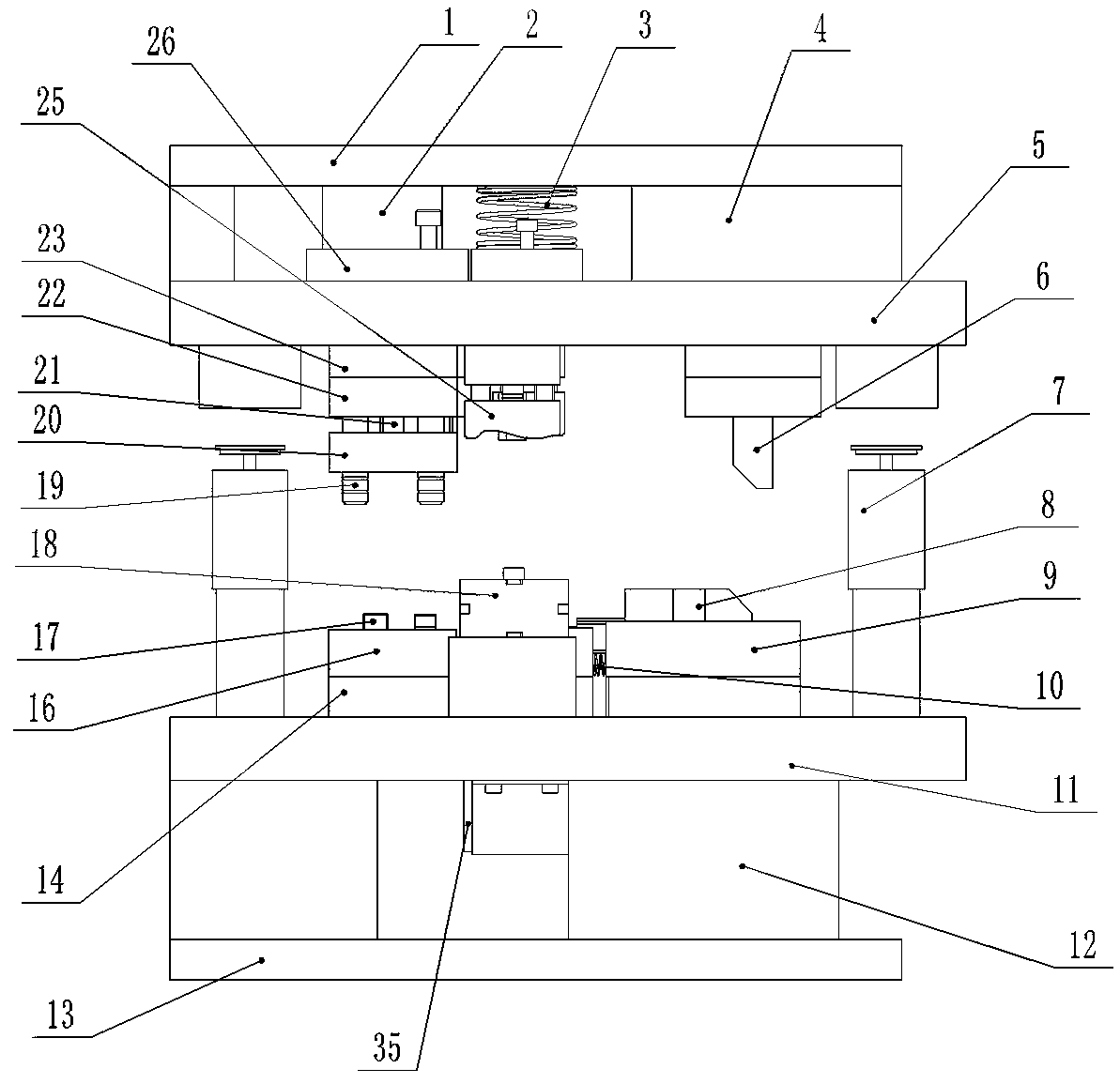

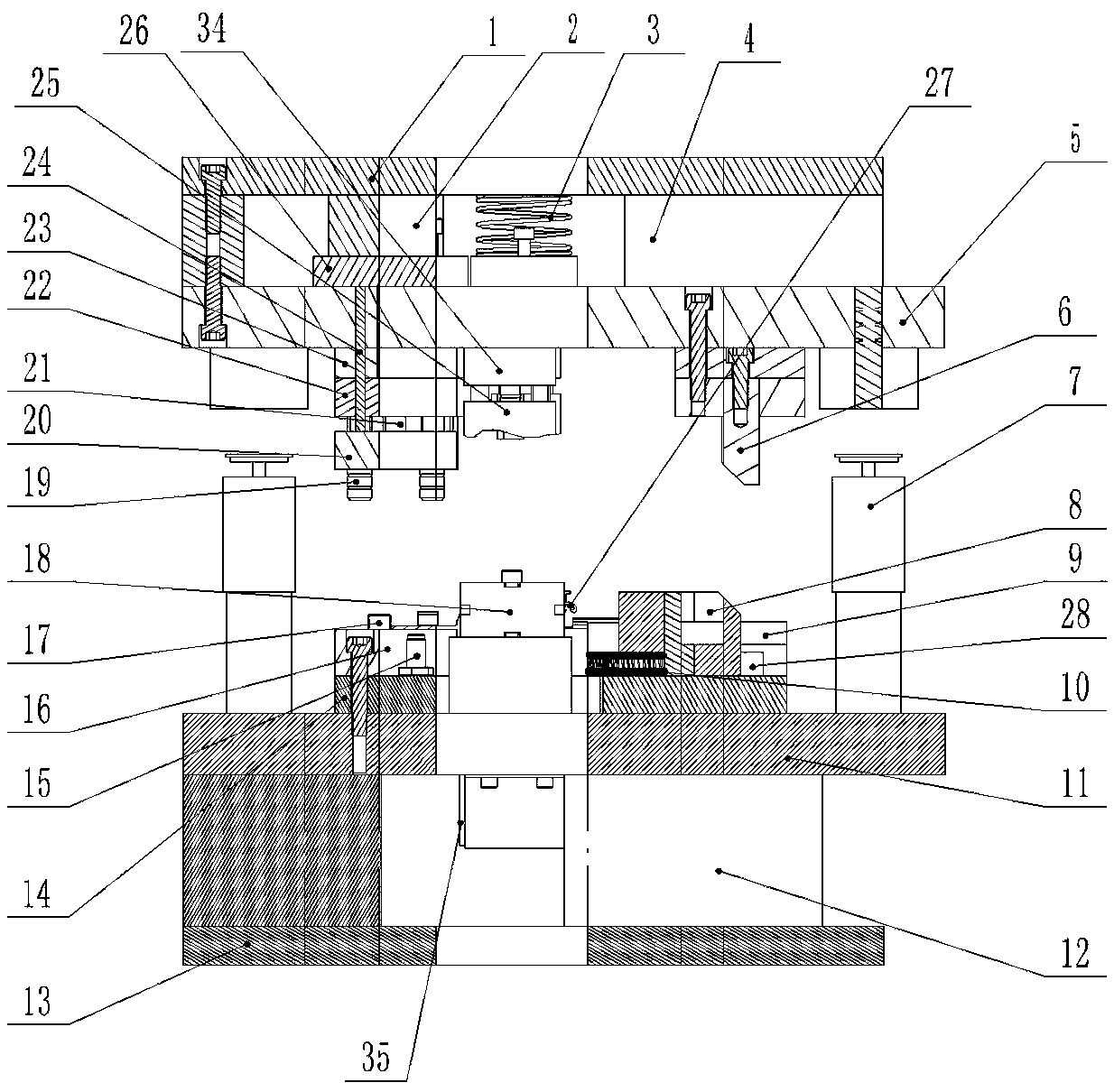

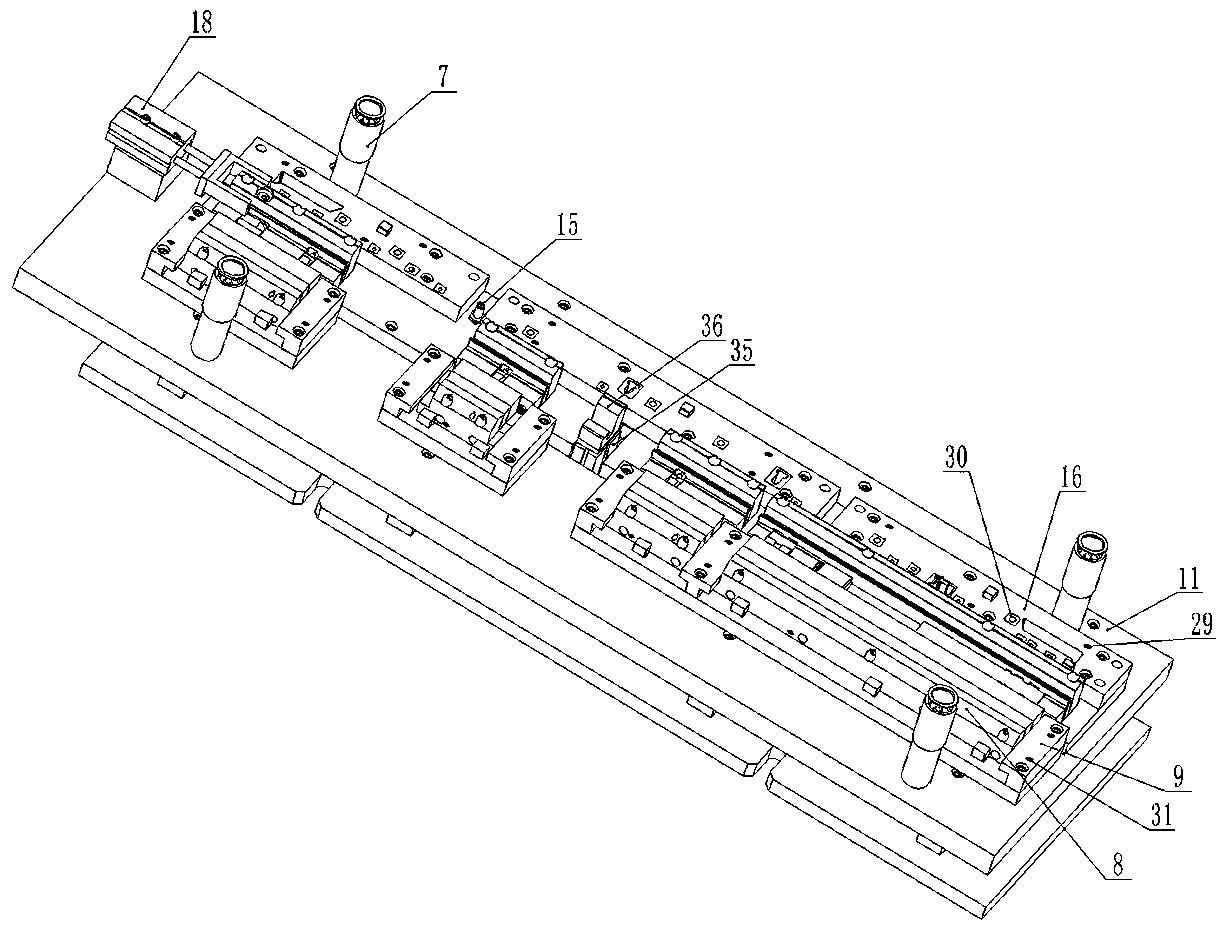

[0032] refer to Figure 1 to Figure 5 , a stamping die for multi-surface forming processing of an automobile sunroof guide rail, comprising an upper die and a lower die, and the upper die and the lower die are connected by a plurality of outer guide columns 7;

[0033] The upper mold includes an upper base 1, an upper vertical plate 4, an upper mold base 5, a return plate 26, a first return spring 3 and a rubber pad 2; the upper base 1, an upper vertical plate 4 and an upper mold base 5 Arranged sequentially from top to bottom and connected and fixed by fixing bolts; the reset plate 26 is arranged on the upper end of the upper mold base 5 and connected by contour bolts 33, and the reset plate 26 can slide up and down along the contour bolts 33 The first return spring 3 and the rubber pad 2 are located between the reset plate 26 and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap