Concrete distributing device and prefabricated part production line

A technology for distributing equipment and concrete, which is applied in the direction of supply equipment, manufacturing tools, ceramic molding workshops, etc., can solve the problems of limited distribution range and insufficient automation, and achieve the effect of high degree of automation, large distribution range, flexible and controllable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

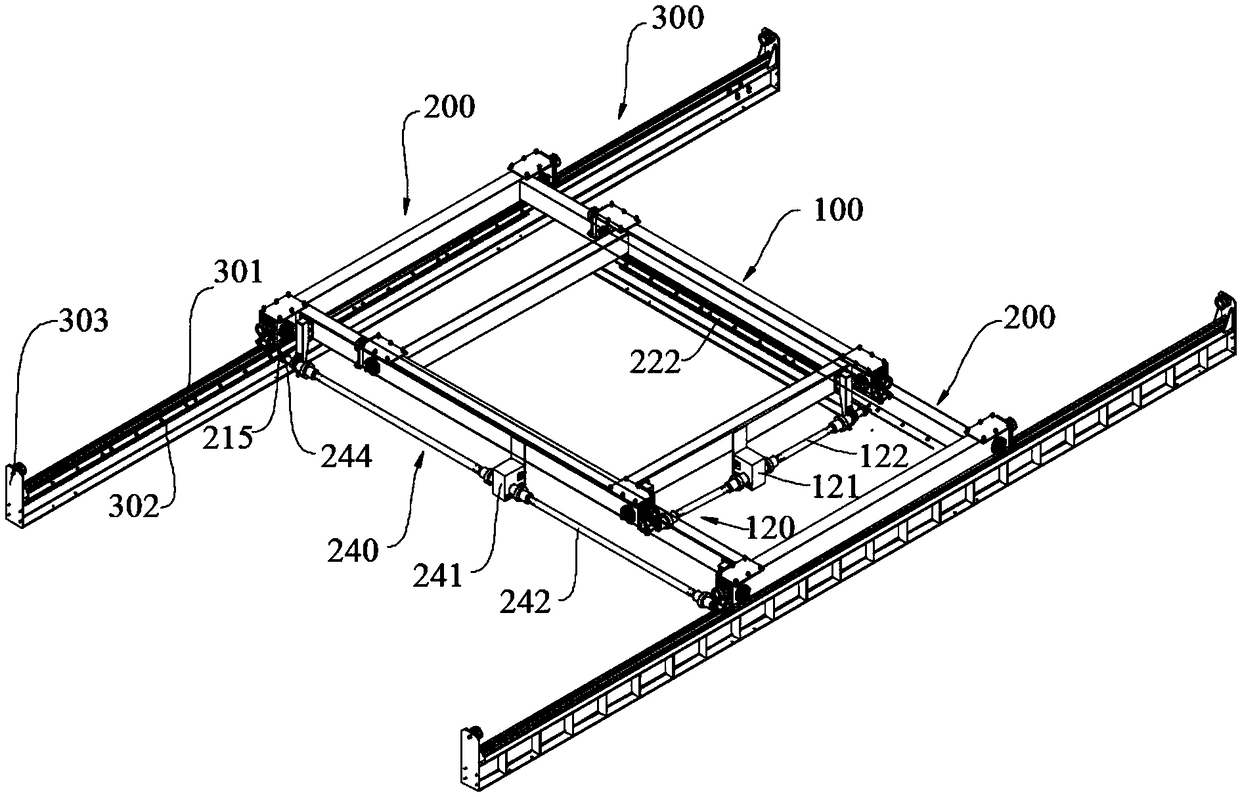

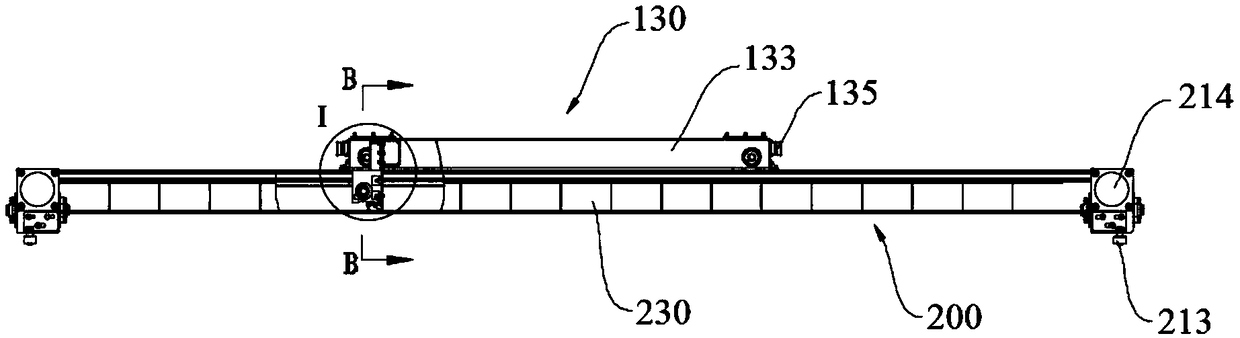

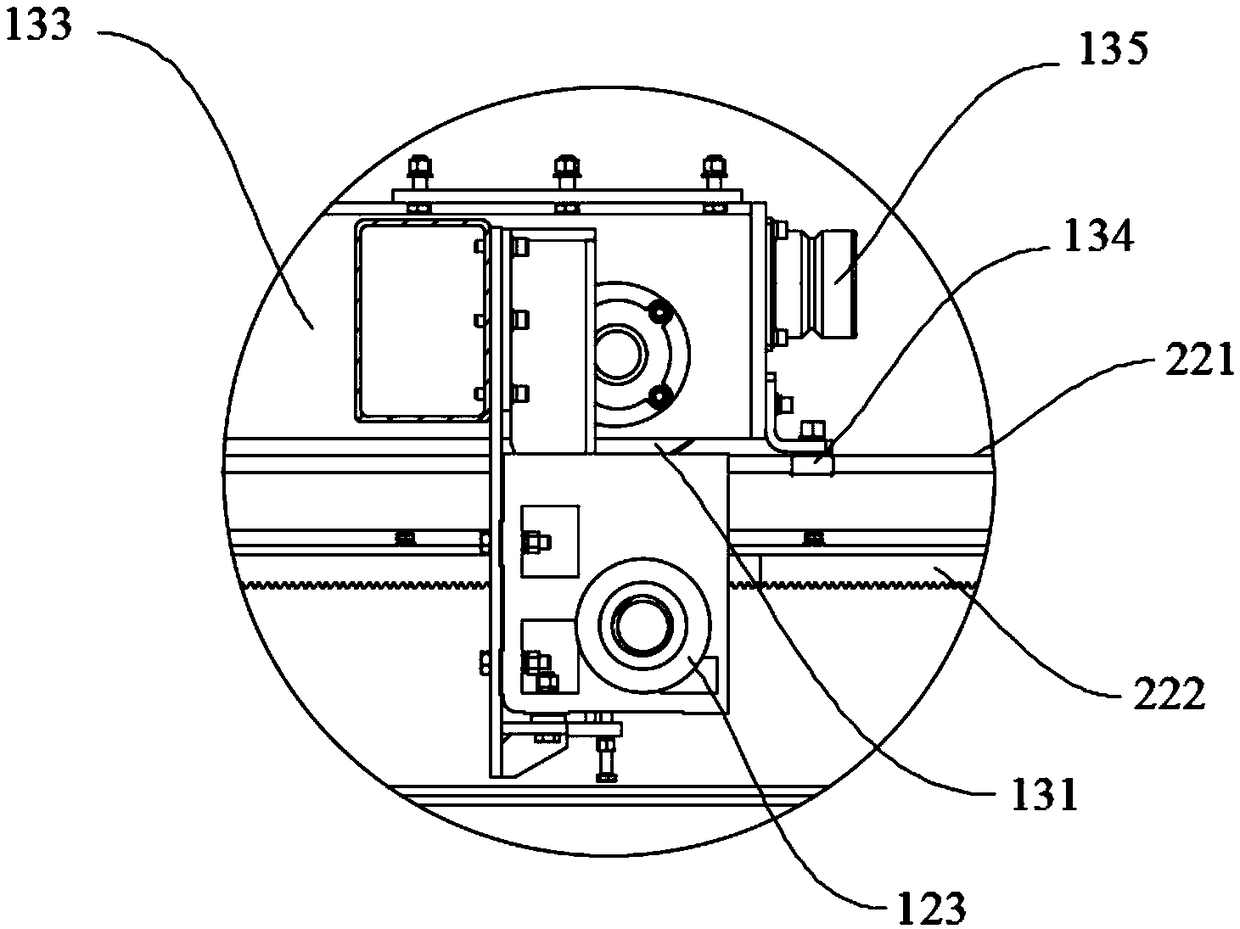

[0029] refer to Figure 1 to Figure 4 , the present embodiment provides a concrete distribution device, the distribution device includes a door frame 300, a cart 200 moving on the door frame 300, a trolley 100 moving on the cart 200, and a distribution mechanism; the distribution mechanism is installed on the trolley 100 . The cart 200 includes two symmetrically arranged first traveling rails 221 and symmetrically arranged two first rack rails 222 , and the first traveling rails 221 are arranged parallel to the first rack rails 222 . The trolley 100 includes two first traveling mechanisms 130 , a first crossbeam 110 and a first transmission mechanism 120 , and two ends of the first crossbeam 110 are vertically connected to corresponding ends of the two first traveling mechanisms 130 . The first transmission mechanism 120 includes a first reducer 121, two first transmission shafts 122 and two first gears 123, one end of each first transmission shaft 122 is connected with the f...

Embodiment 2

[0043] refer to figure 1 , this embodiment provides a concrete distribution device, its structure is basically the same as that of the concrete distribution device in Embodiment 1, the difference is that the cart 200 and the door frame 300 are also driven by rack and pinion track meshing transmission. The second traveling mechanism 210 of the cart 200 moves on the second traveling track 301 of the mast 300 .

[0044] Specifically, the mast 300 includes two symmetrically arranged second running rails 301 and two symmetrically arranged second rack rails 302 , and the second running rails 301 and the second rack rails 302 are arranged in parallel. The cart 200 also includes two second traveling mechanisms 210, a second crossbeam 220, a third crossbeam 230 and a second transmission mechanism 240, and a first traveling rail 221 and a first traveling rail 221 and a The first rack track 222 . Both ends of the second beam 220 are vertically connected to one end of the two second run...

Embodiment 3

[0049]This embodiment provides a prefabricated part production line, and the prefabricated part production line includes the concrete distributing device provided in the above-mentioned embodiments. On the prefabricated parts production line, the transportation device can directly obtain the concrete slurry from the mixing station or the transfer station, transport it to the concrete distribution device through the conveying track, and transfer the concrete slurry to the distribution mechanism. Through the movement of the cart 200 on the door frame 300, the material distribution mechanism is sent to the top of the mold table, and then the trolley 100 moves back and forth on the cart 200 to distribute materials to the mold table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com