High-intensity multi-directional FDM 3D printing method based on stereoscopic vision monitoring

A stereo vision and multi-directional technology, applied in stereo systems, 3D object support structures, program control, etc., can solve the problems of high material cost, low printing accuracy, and inconsistent printing directions, so as to save support structures, ensure printing accuracy, The effect of enhancing the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of this application will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the absence of conflicts, the multi-directional 3D printing, stereo vision inspection, and laser heating enhanced interlayer strength of this application are applicable to all three-dimensional models .

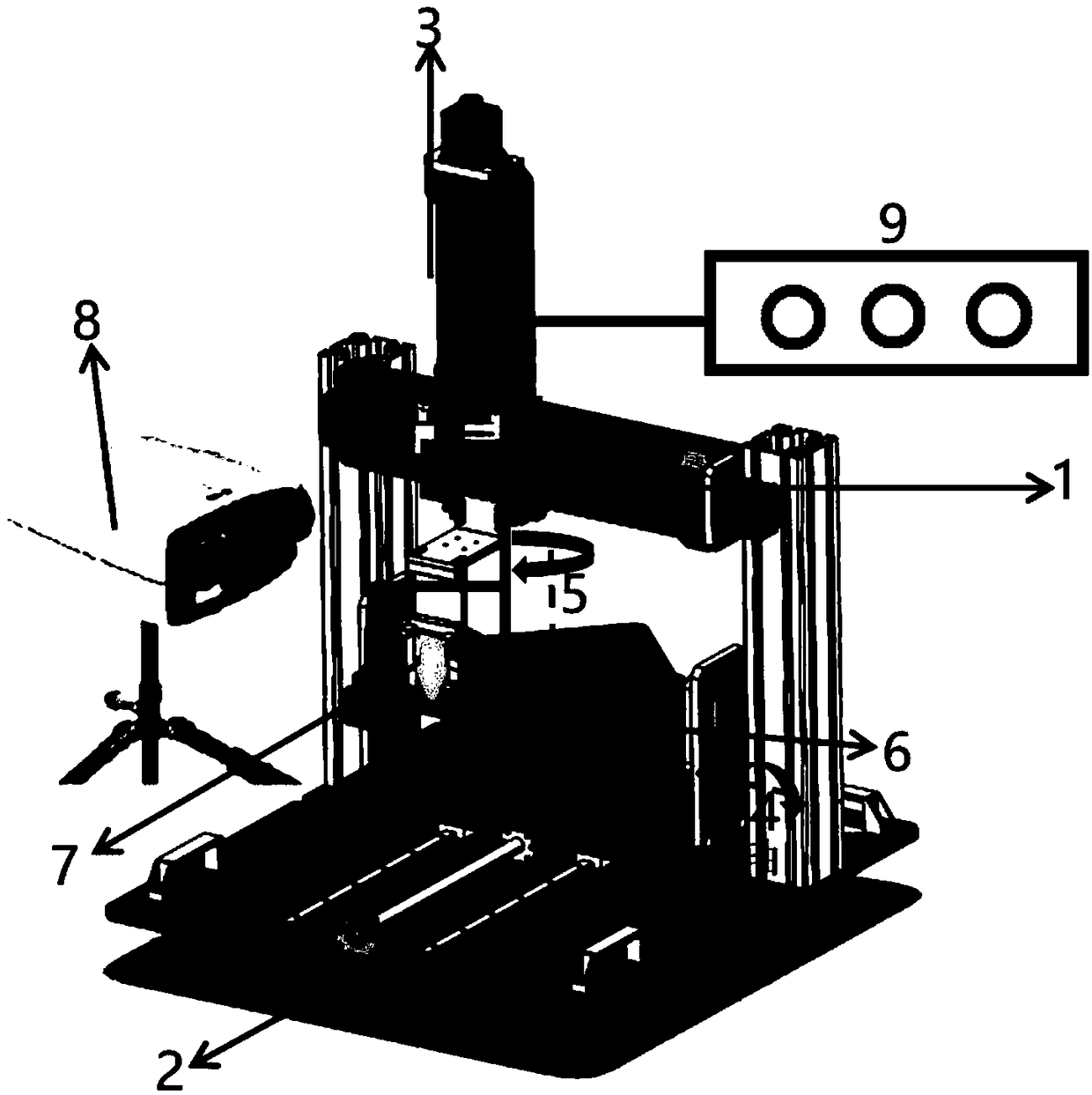

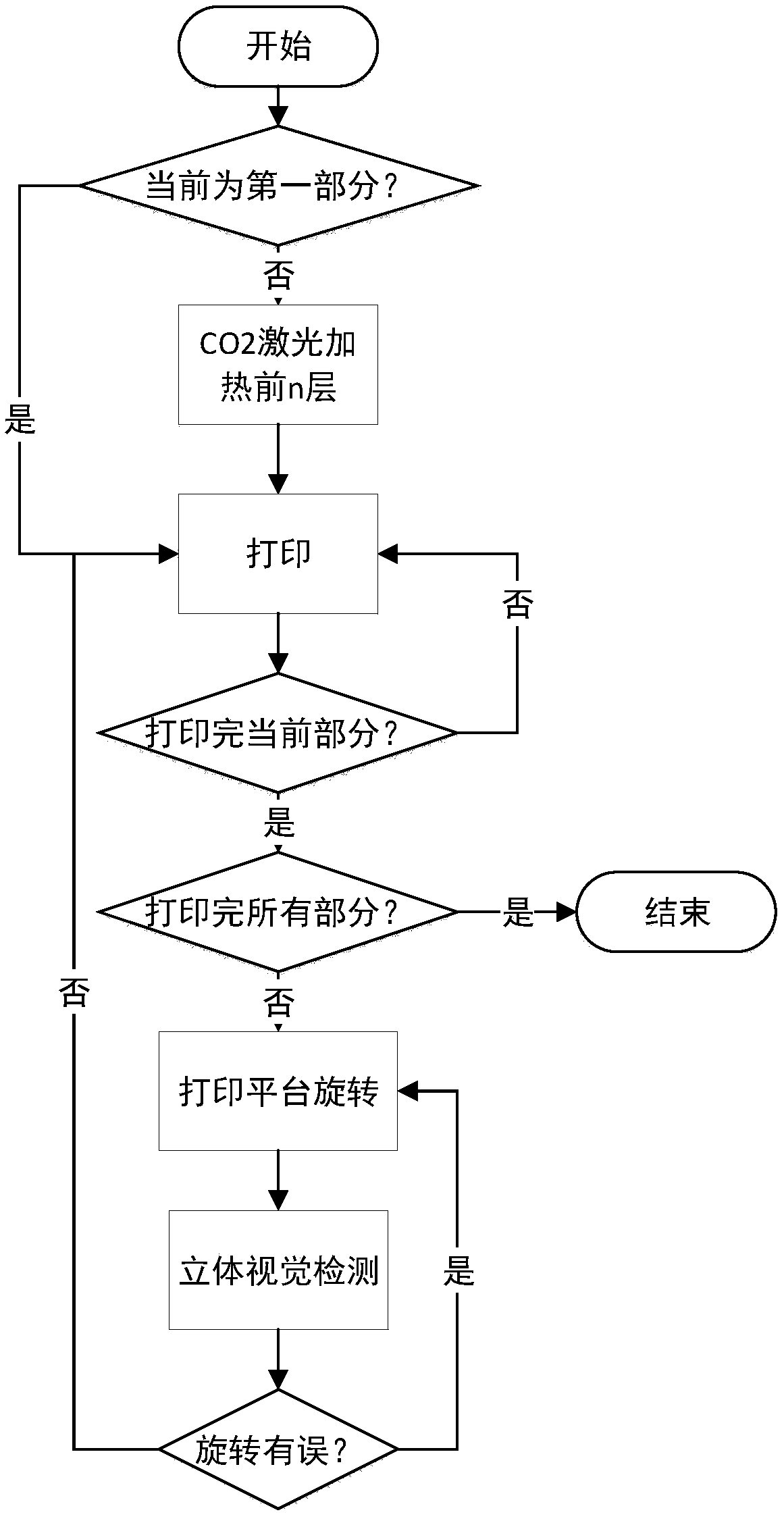

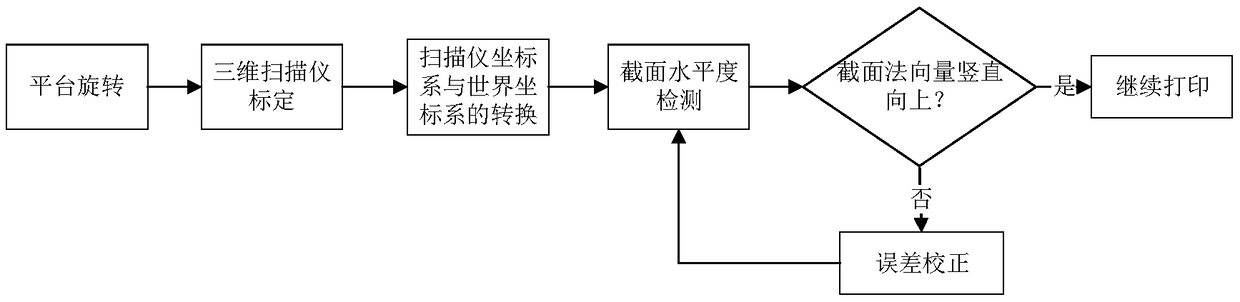

[0031] figure 1 Shown is a high-intensity multi-directional FDM 3D printer for stereo vision monitoring. Its structure includes five-axis mechanical devices: 1.x axis, 2.y axis, 3.z axis, 4.A axis, 5.B axis; printing And laser heating device: 6. Printing platform, 7. Printing extrusion head equipped with laser heating device (see the structure for details Figure 5 and Figure 6 shown), 9. laser; stereo vision detection device: 8. three-dimensional scanner.

[0032] Among them, the five-axis device is mainly used to complete the printing path and can be linked; the printing and laser heating device is used to extrude the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com