Improved washing kettle for producing p-chloropropiophenone

A chloropropiophenone, kettle body technology, applied in the separation/purification of carbonyl compounds, organic chemistry and other directions, can solve the problems of not meeting the needs of use, poor washing effect, incomplete impurity removal, etc., to improve the washing effect, improve the Mixing efficiency, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

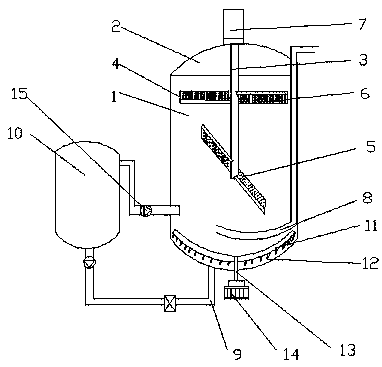

[0020] Such as figure 1 Shown, as the first embodiment of the present invention, a kind of improved water-washing still that produces p-chloropropiophenone uses, comprises still body 1, and the upper part of still body 1 is provided with the loam cake 2 of sealing, and described still body 1 There is a stirring device inside, and the stirring device includes a stirring shaft 3. The upper end of the stirring shaft 3 is connected with the motor 7 arranged on the upper cover 2, and the stirring shaft 3 inserted into the kettle body 1 is from top to bottom An upper agitator 4 and a lower agitator 5 are provided, and through holes 6 are evenly distributed on the blades of the two agitators. The blade axes of the upper agitator 4 and the lower agitator 5 are perpendicular to each other, and the upper agitator 4 and the stirring blades of the lower agitator 5 all include a set of left paddles and right paddles fixedly arranged on both sides of the transmission shaft, and the upper co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com